Fatty acid amide MIPA as well as preparation method and application thereof

A fatty acid amide and fatty acid technology, applied in the field of non-ionic surfactants, can solve the problems of poor foaming performance, oxidative yellowing, darkening of product color, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The present invention provides a kind of preparation method of fatty acid amide MIPA described in above-mentioned technical scheme, comprises the following steps:

[0045] Raise the temperature of the fatty acid to 150°C-200°C, slowly add isopropanolamine dropwise, react at constant temperature for 6h-12h, and post-process to obtain fatty acid amide MIPA;

[0046] The fatty acid comprises 50-100 wt% of lauric acid, 0-25 wt% of myristic acid, 0-15 wt% of palmitic acid and 0-15 wt% of stearic acid.

[0047] The method provided by the invention adopts one-step reaction, the process is simple, no catalyst action is needed, and the content of free amine in the prepared product is low; the unreacted monoisopropanolamine is recovered and reused, and the cost is effectively reduced.

[0048] In the present invention, the molar ratio of the fatty acid to monoisopropanolamine is 1:1.0-1.5.

[0049] The time for the constant temperature reaction is 6h to 12h; in specific embodime...

Embodiment 1

[0065] Add 165g of lauric acid, 60g of myristic acid, 45g of palmitic acid and 30g of stearic acid into the reaction kettle, raise the temperature to 170°C, slowly add 135g of monoisopropanolamine dropwise, react at constant temperature for 12 hours, then vacuumize, the degree of vacuum is - 0.095MPa, recover the unreacted monoisopropanolamine, lower the temperature, and cool to obtain the crude product; after the crude product is refined, a white to light yellow solid is obtained, namely fatty acid amide MIPA.

[0066] The composition of the fatty acid amide MIPA prepared by embodiment 1 is shown in Table 1:

[0067] The composition of the fatty acid amide MIPA that table 1 embodiment 1 prepares

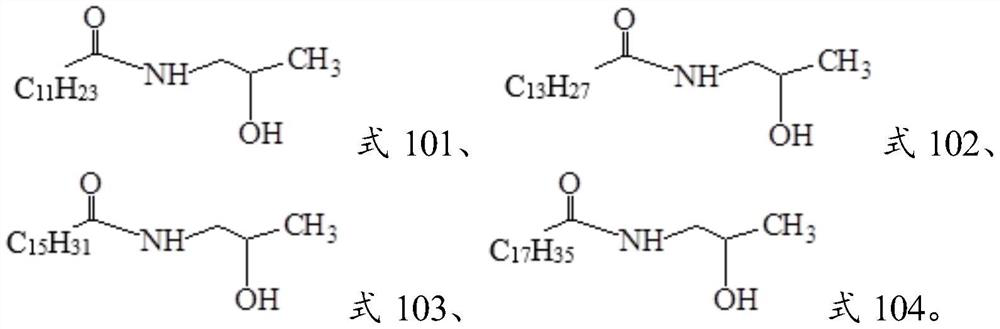

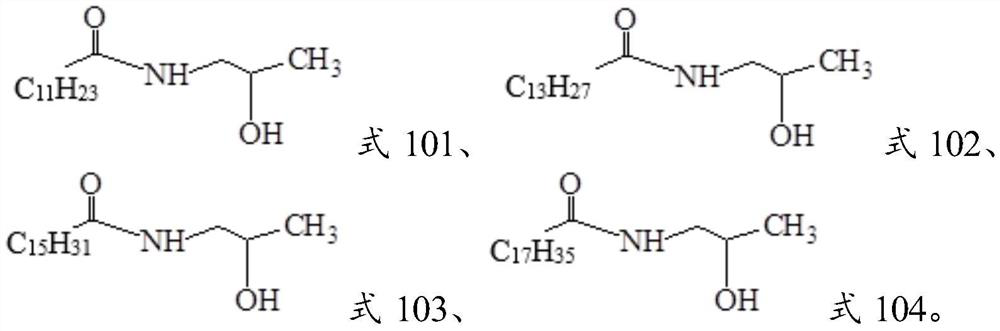

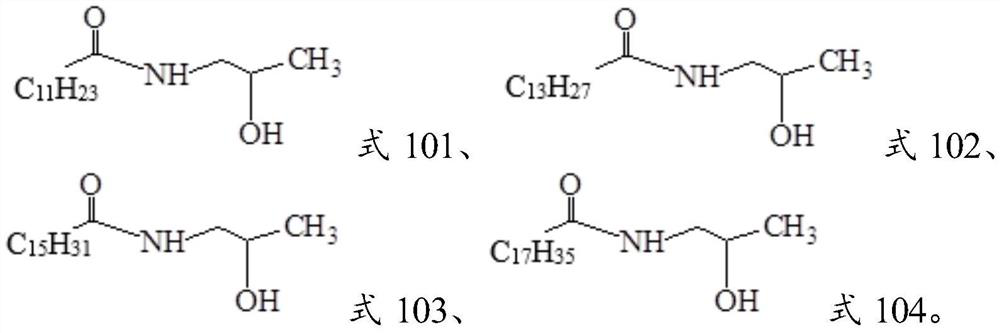

[0068] components Ratio / wt% Compound shown in formula 101 55.0 Compound shown in formula 102 20.0 Compound shown in formula 103 15.0 Compound shown in formula 104 10.0

[0069] After testing, the color (Gardner) of the product prepared in Exam...

Embodiment 2

[0071] Add 150g of lauric acid, 60g of myristic acid, 45g of palmitic acid and 45g of stearic acid into the reaction kettle, raise the temperature to 160°C, slowly add 130g of monoisopropanolamine dropwise, react at constant temperature for 11 hours, and then vacuumize, the degree of vacuum is - 0.098MPa, recover the unreacted monoisopropanolamine, lower the temperature, and cool down to obtain the crude product; after the crude product is refined, a white to light yellow solid is obtained, namely fatty acid amide MIPA.

[0072] The composition of the fatty acid amide MIPA prepared by embodiment 2 is shown in Table 2:

[0073] The composition of the fatty acid amide MIPA that table 2 embodiment 2 prepares

[0074] components Ratio / wt% Compound shown in formula 101 50.0 Compound shown in formula 102 20.0 Compound shown in formula 103 15.0 Compound shown in formula 104 15.0

[0075] After testing, the color (Gardner) of the fatty acid amid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com