Steel for 540 MPa-grade LPG fuel tank and manufacturing method of steel

A manufacturing method and fuel tank technology, applied in the field of steel production, can solve the problems of reduced welding performance, high alloy cost, and extended delivery time, and achieve the effects of no reduction in strength and toughness, high strength, and excellent low-temperature toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

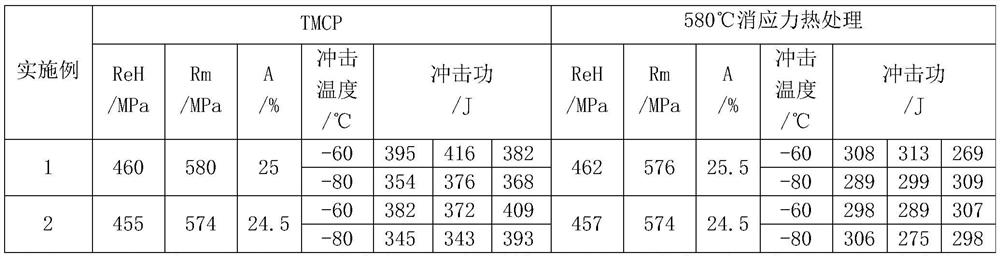

Embodiment 1

[0030] A 540MPa grade LPG fuel tank steel provided in this example has the following chemical composition and mass percentages: C: 0.07%, Si: 0.40%, Mn: 1.60%, P: 0.008%, S: 0.002%, Alt: 0.058%, N: 0.0038%, Nb: 0.025%, Ti: 0.014%, Cr: 0.20%, Ni: 0.20%, and the balance is Fe and unavoidable impurities.

[0031] The manufacturing method includes molten iron desulfurization pretreatment, converter smelting, LF refining, RH vacuum treatment, continuous casting, slab heating, controlled rolling and controlled cooling after rolling. Specifically: heat a 260mm slab to 1150°C, hold it for 300min, and carry out two Stage controlled rolling, the rolling temperature in the recrystallization zone is 1050°C; the thickness of the billet to be warmed is 80mm, the deformation in each pass is 32mm, the rolling start temperature in the non-recrystallization zone is 785°C, and the final rolling temperature is 770°C. The steel plate is 30mm, weak cooling is adopted after rolling, the cooling rate...

Embodiment 2

[0033] A kind of 500MPa grade LPG fuel tank steel provided by this embodiment differs from Embodiment 1 in that:

[0034] Its chemical composition and mass percentage are as follows: C: 0.09%, Si: 0.40%, Mn: 1.55%, P: 0.008%, S: 0.002%, Alt: 0.040%, N: 0.0040%, Nb: 0.005%, Ti: 0.010%, Cr: 0.10%, Ni: 0.25%, Cu: 0.10%, and the balance is Fe and unavoidable impurities.

[0035] Heat the 320mm billet to 1130°C, keep it warm for 300min, and carry out two-stage controlled rolling. The rolling temperature in the recrystallization zone is 1050°C; The rolling start temperature is 765°C, the finish rolling temperature is 760°C, the steel plate after rolling is 50mm, water cooling is adopted after rolling, the cooling rate is 10°C / s, the reddening temperature is 540°C, and then air-cooled to room temperature.

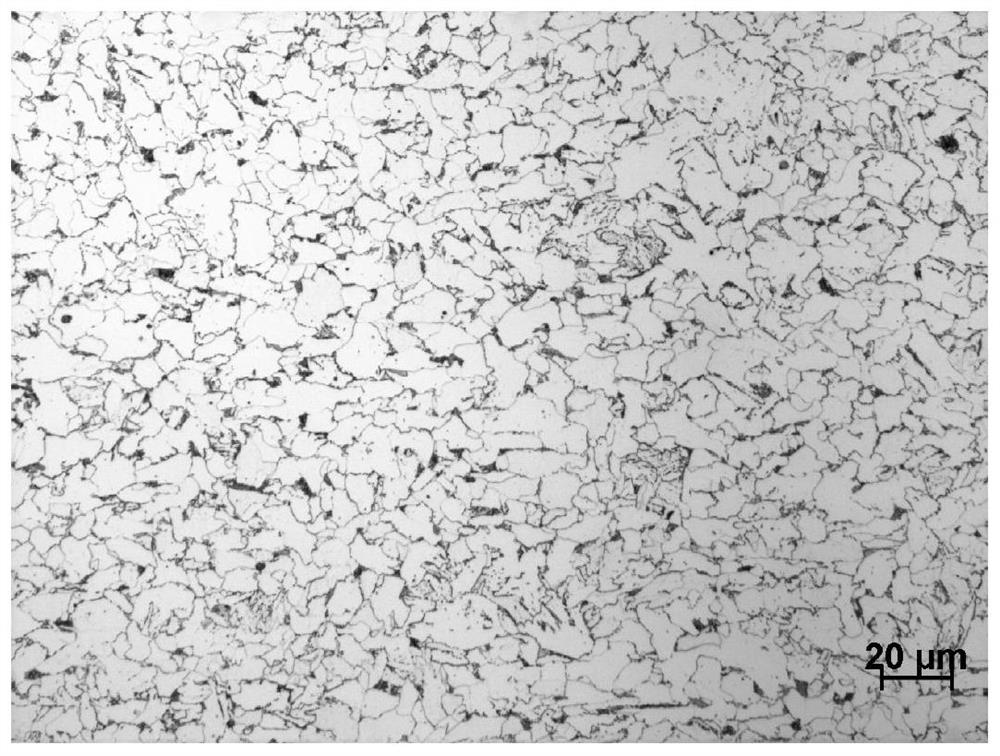

[0036] Depend on figure 1 It can be seen that the microstructure of the steel plate is ferrite + bainite + a small amount of pearlite, the grain size of ferrite is 9-11.5, the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com