Self-powered environment corrosion monitoring system for wind power equipment

A technology for environmental corrosion and monitoring systems, applied in weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve problems such as qualitative and quantitative difficulties, stripping insulation materials, and many factors affecting eddy current effects, etc., to achieve convenient analysis And the effect of early warning, easy installation and movement, and long battery life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

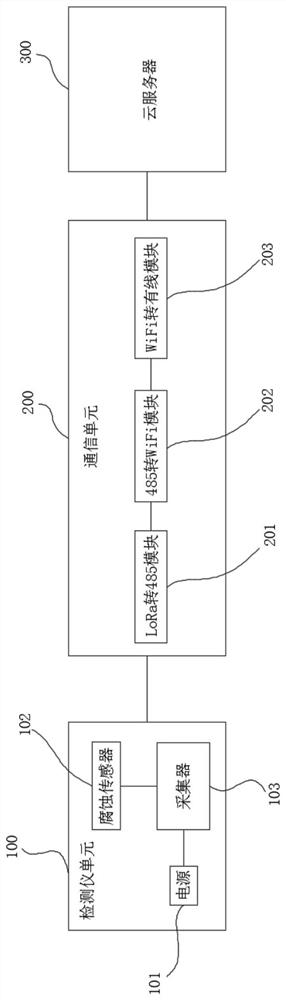

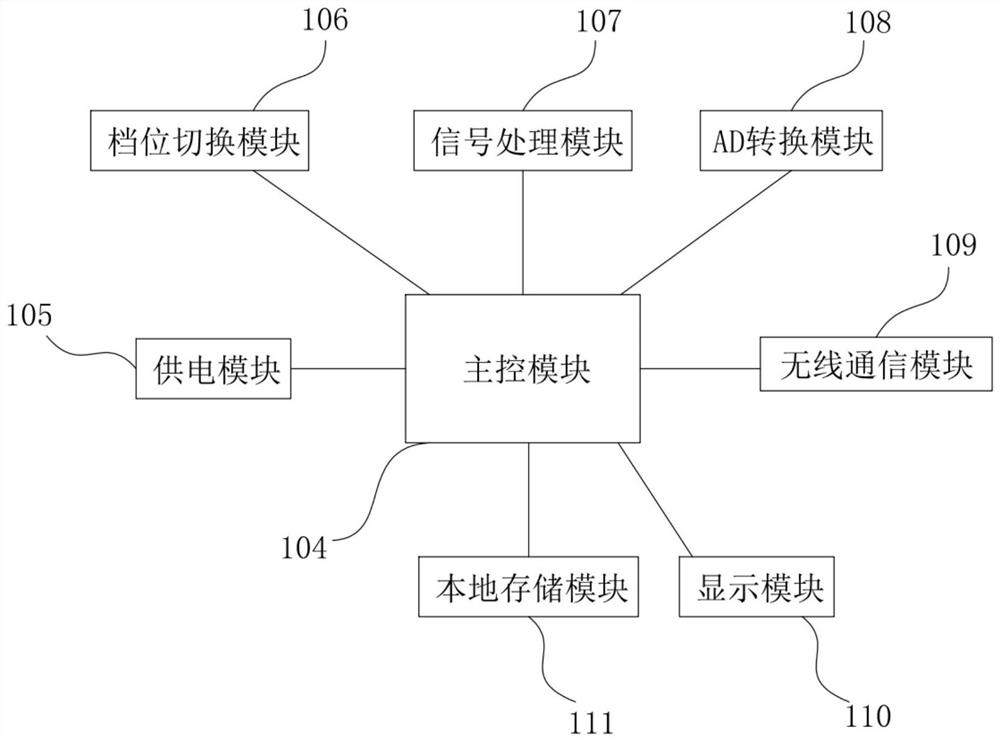

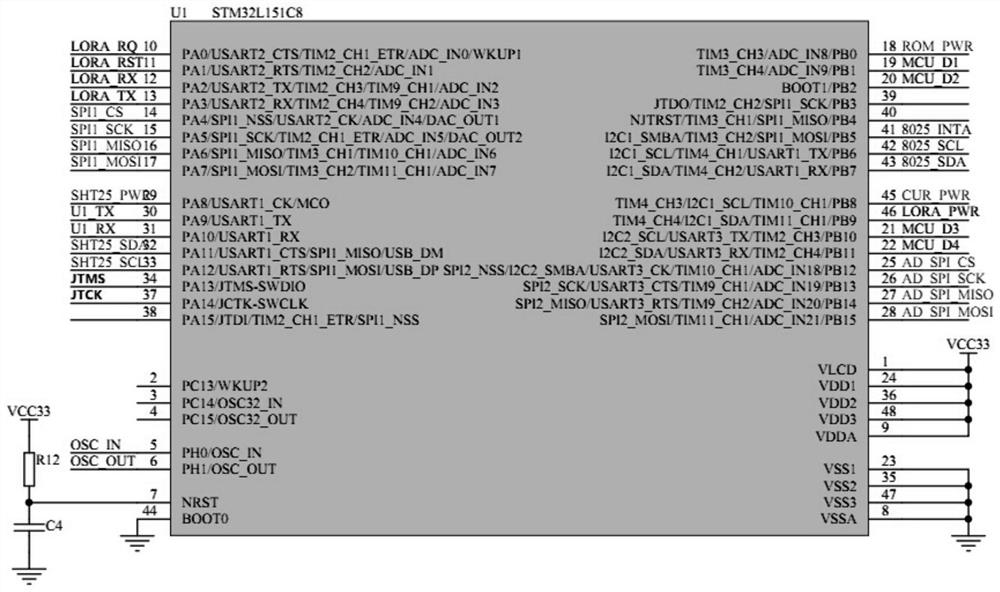

[0027] Please refer to Figure 1 to Figure 17 , in this embodiment, the present invention provides a self-powered environmental corrosion monitoring system for wind power equipment, including: several detector units 100, and a cloud connected to the detector units 100 through the communication unit 200 Server 300. In this solution, the detector unit 100 includes several corrosion sensors 102 , a power supply, and a collector 103 . The power supply is used to provide the power required for the collector 103 and the corrosion sensor 102 to work. The corrosion sensor 102 is used to detect the corrosion of wind power equipment. The collector 103 includes: a main control module 104, a power supply module 105 electrically connected to the main control module 104, a gear switching module 106, a signal processing module 107, an AD conversion modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com