Device and method for treating containers filled with foamable liquid filling material

A liquid filling and container technology, applied in the field of container equipment, can solve problems such as errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

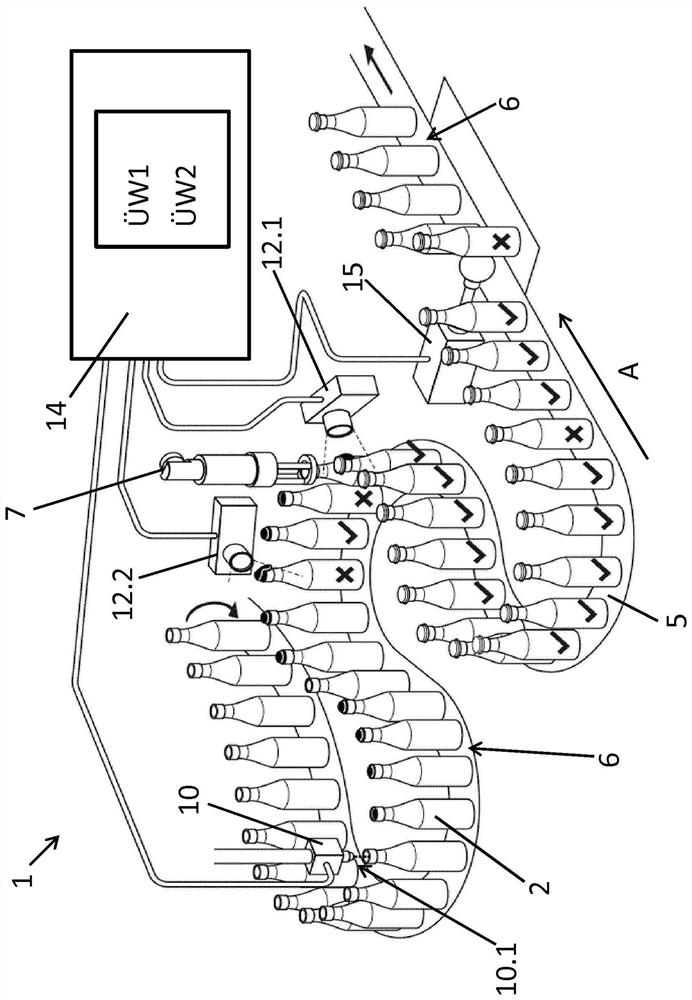

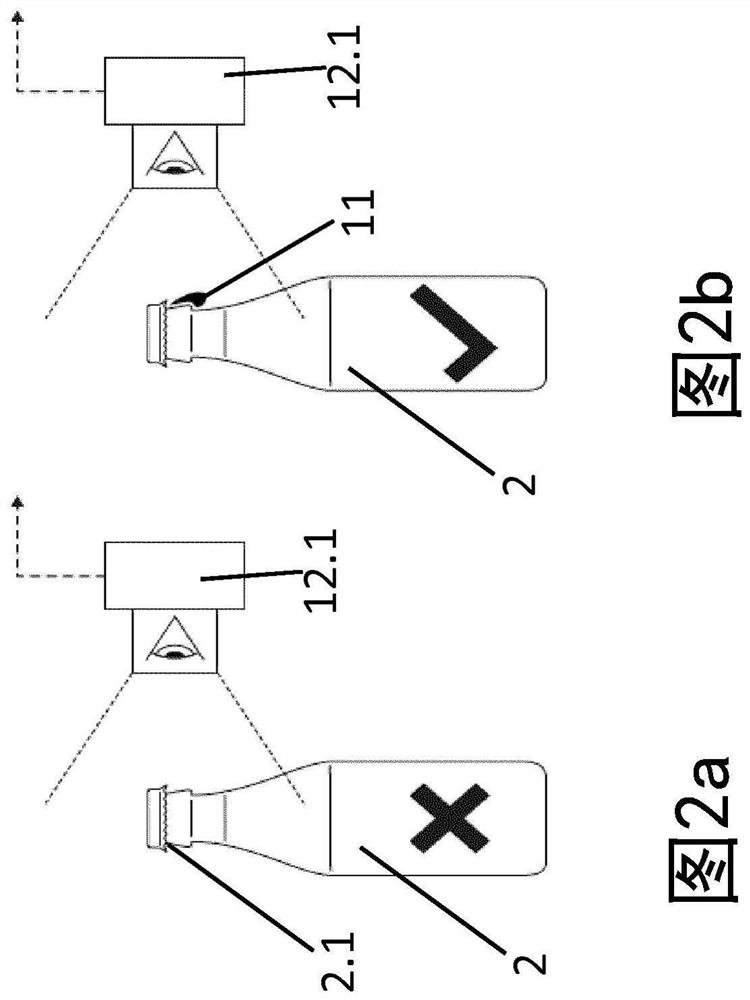

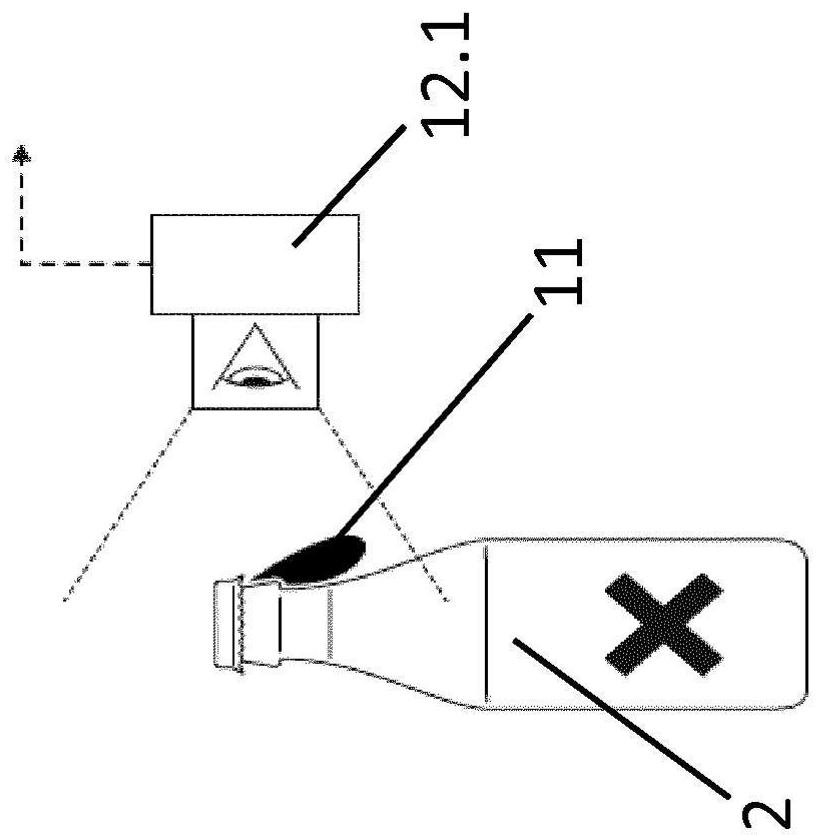

[0032] figure 1 An embodiment of a device according to the invention for processing containers 2 , such as bottles, jars or the like, which have been filled with a foamable liquid filler is shown. In this case, the device according to the invention can in particular be part or a component part of a plant for filling containers 2 , but alternatively can also be connected downstream of such a plant for filling containers in the conveying direction A of the containers 2 .

[0033] In particular, the device according to the invention has: at least one foaming unit 10 arranged along the conveying path 6; a closing station 7 following along the conveying path 6 in the conveying direction A; and following along the conveying path 6 Discharge unit 15 thereafter.

[0034] For this purpose, the facilities for filling the containers 2, which are not shown in detail in the drawings, can in particular comprise filling machines of the orbital type, which have corresponding rotors which can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com