High-speed solid-liquid separation equipment of high-flow circulating granulation fluidized bed

A solid-liquid separation, fluidized bed technology, applied in the direction of precipitation separation, separation method, special binder granulation, etc., can solve the problem of small amount of water to be treated, and achieve the effect of convenient water discharge, reduced equipment installation height, and simple and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

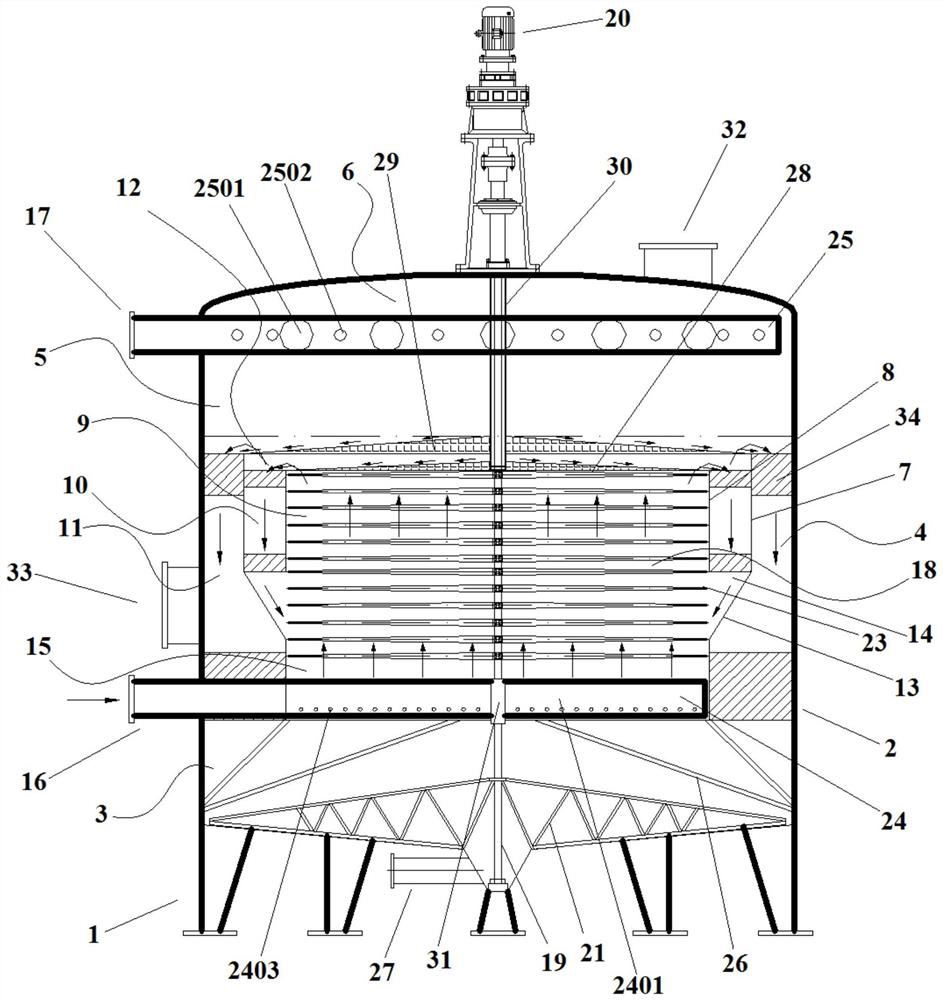

[0050] This embodiment provides a high-speed solid-liquid separation equipment for a large-flow circulating granulation fluidized bed, including the main device of the fluidized bed, such as Figure 1 to Figure 5 As shown, the main device of the fluidized bed includes a base frame 1, on which a tank body 2 is fixedly installed. Water District 6;

[0051] A middle cylinder 7 and an inner cylinder 8 are installed in the circulating granulation zone 4, and the tank body 2, the middle cylinder 7 and the inner cylinder 8 are arranged coaxially from the outside to the inside, and the inner cylinder 8 is a granulation fluidization zone 9, and the inner cylinder 8 The recirculation area 10 is between the middle cylinder 7 and the middle cylinder 7, and the sludge settlement area 11 is between the middle cylinder 7 and the tank body 2;

[0052] The tops of the middle cylinder 7 and the inner cylinder 8 are open and the top of the middle cylinder 7 is higher than the top of the inner c...

Embodiment 2

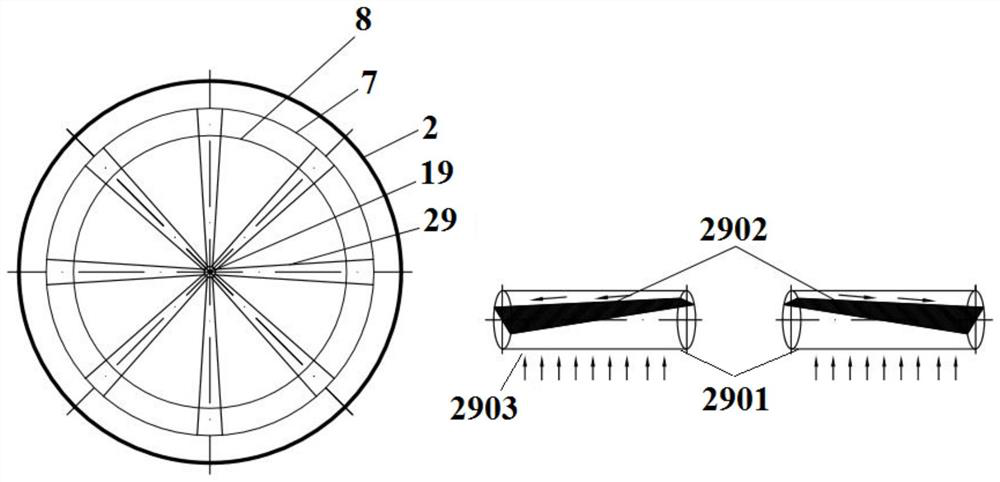

[0084] This embodiment provides a high-speed solid-liquid separation equipment for a large-flow circulating granulation fluidized bed, which is basically the same as the high-speed solid-liquid separation equipment for a large-flow circulating granulation fluidized bed in Example 1. The difference is that this implementation In the example, the separation zone 5 can also be equipped with a separation device, and different separation devices can be selected according to the difference in water quality. Such as vertical vortex enhanced separation device or suspension layer filtration separation device.

[0085] The vertical eddy current strengthening separation device adopts the vertical eddy current strengthening separation device known in the prior art.

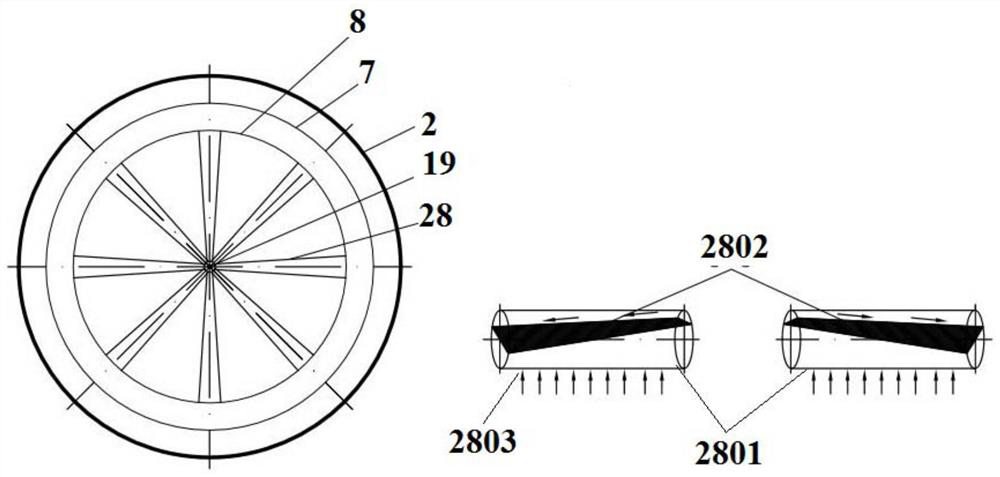

[0086] Such as Figure 6 As shown, the suspension layer filtration solid-liquid separation device 22 is divided into upper and lower parts, the upper part is a static suspension layer 2201, the lower part is a stirring suspe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com