Surface grinding and cleaning device for artificial stone

A cleaning device and artificial stone technology, applied in the direction of dry gas arrangement, cleaning method and utensils, cleaning method using liquid, etc., can solve the problems of high manual labor intensity, low work efficiency, inconvenience, etc., to reduce labor intensity, High working efficiency and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

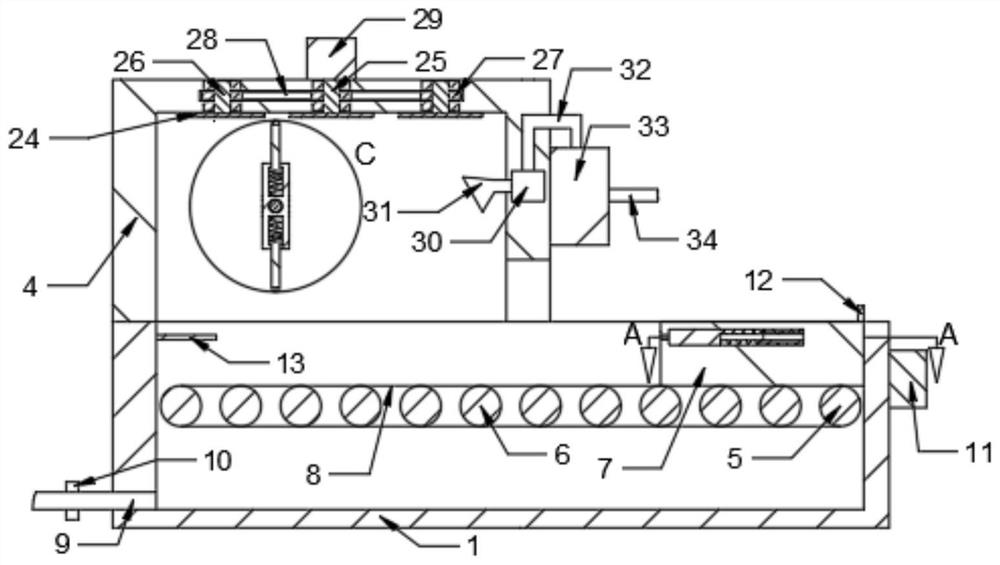

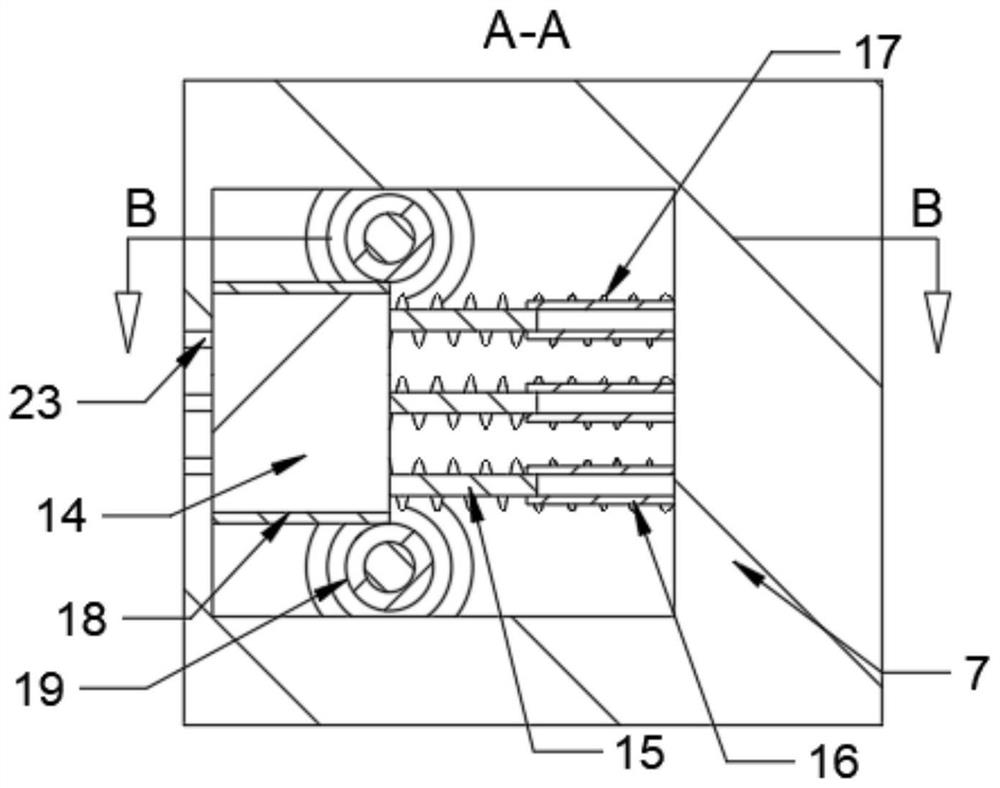

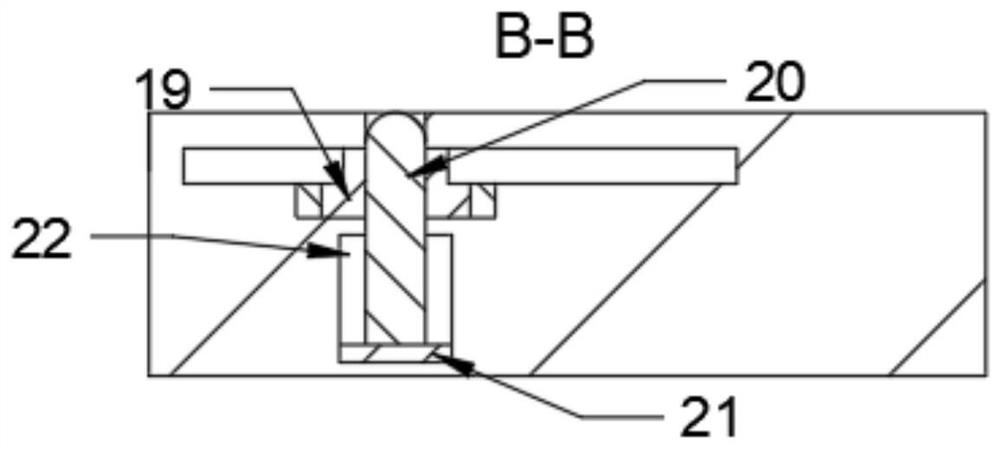

[0024] see figure 1 , figure 2 and Figure 5 , in an embodiment of the present invention, a device for flat grinding and cleaning artificial stone surfaces includes a base 1; three sets of push rods 13 are fixedly installed on the top of one side of the base 1; device; one end of the transmission device is fixedly installed with a placement seat 7; the middle part of the side of the placement seat 7 close to the push rod 13 is slidingly provided with a square block 14; the two sides of the square block 14 are symmetrically fixed and fixed There is a toothed plate 18, and the toothed plate 18 drives and engages the supporting device; the side of the square block 14 close to the push rod 13 is uniformly arranged with three groups of through holes 23; the side of the square block 14 away from the push rod 13 is provided with Elastic device; the side away from the push rod 13 on the placement seat 7 is symmetrically fixed with a stop bar 12 to prevent the artificial stone from ...

Embodiment 2

[0031] see figure 1 and Figure 4 , the top of the installation shell 4 is provided with an air-drying device; the side of the installation shell 4 close to the push rod 13 is rotated with a fifth shaft 35; the fifth shaft 35 is fixed with a square plate 36; A chute 38 is provided above and below the square plate 36; a second spring 37 is slidably provided on one side of the chute 38 close to the fifth rotating shaft 35; A support rod 2 is provided on the side, and one end of the support rod 2 close to the fifth rotating shaft 35 is slidably disposed in the slide groove 38 ; the end of the support rod 2 away from the second spring 37 is fixedly installed with a sponge 3 . The two sets of sponges 3 provided can respectively wipe the artificial stone when cleaning and when air-drying, and the air-drying device can speed up the rapid air-drying of the artificial stone after cleaning.

[0032] see figure 1 , the air-drying device includes a fan blade 24, a third shaft 25, a fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com