Piston rubber coating production line

A production line and encapsulation technology, which is applied in the field of shock absorber piston production equipment, can solve the problems of reduced production efficiency, low efficiency, and large energy consumption, and achieve the effects of reducing use and errors, preventing temperature shifting, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

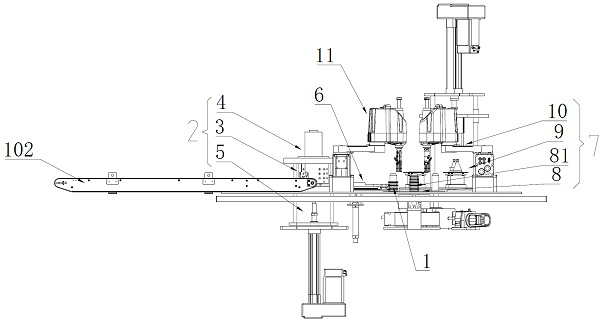

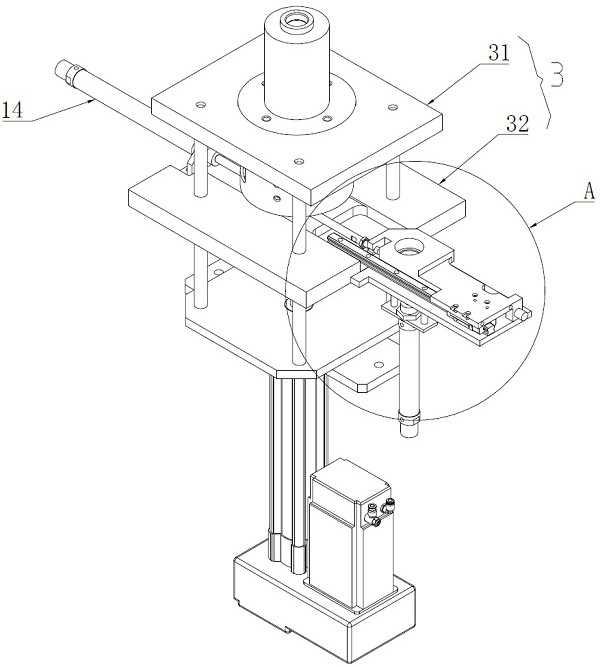

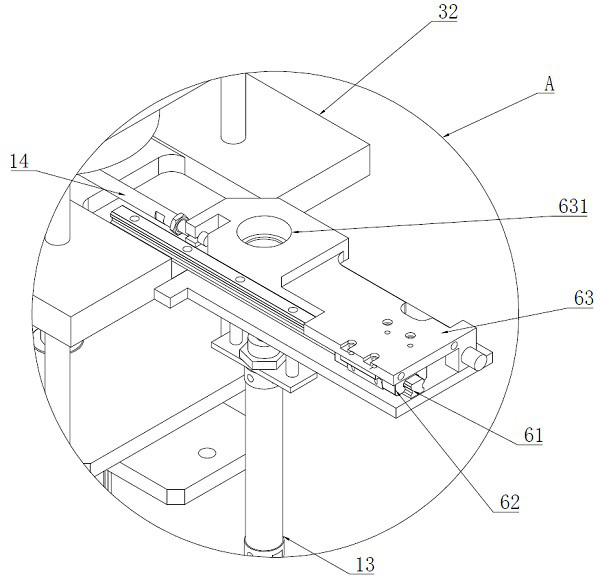

[0055] see figure 1 , figure 2 , Figure 4 , Figure 6 , Figure 7 , Figure 8 , Figure 13 , Figure 14 and Figure 15 As shown, a piston lagging production line, which wraps the film 1 on the piston ring 101 to make piston lagging, has:

[0056] The conveying line 102 for the product to be processed that conveys the piston ring 101;

[0057] A turntable 8 for conveying the film 1;

[0058] A pre-encapsulation device 7 for pre-encapsulating the film 1 on the piston ring 101;

[0059] A forming device 2 for forming the pre-encapsulated piston ring 101;

[0060] Transferring the film 1 and piston ring 101 to the pre-encapsulation device 7, and transferring the pre-encapsulated piston ring 101 to the forming device 2, and transferring the piston encapsulation to a finished product delivery line 103;

[0061] A turntable 9 with a feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com