FeSiAl flaky wave-absorbing material and preparation method thereof

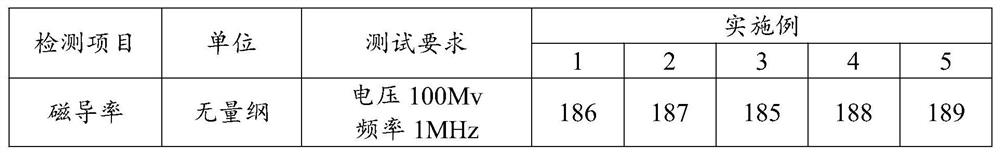

A wave-absorbing material and sheet-like technology, applied in the field of FeSiAl sheet-like wave-absorbing material and its preparation, can solve the problems of weak electromagnetic shielding ability, complicated preparation process, low magnetic permeability, etc., and achieve strong electromagnetic shielding ability and good absorption. Wave effect, high permeability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A FeSiAl sheet absorbing material

[0029] The FeSiAl sheet-shaped wave-absorbing material is made of FeSiAl wave-absorbing powder and colloid with a mass ratio of 10:0.45. The mass fractions of Fe, Si, and Al in the FeSiAl wave-absorbing powder are Fe9.4%, Si6.1%, Al84 .5%; Among them, the colloid is water-based polyurethane.

[0030] The preparation steps are as follows:

[0031] Step 1. Preparation of FeSiAl alloy powder: After the mass fraction of Fe, Si, and Al is smelted, centrifuged, and ball milled, FeSiAl alloy powder with a particle size of 100 μm is obtained;

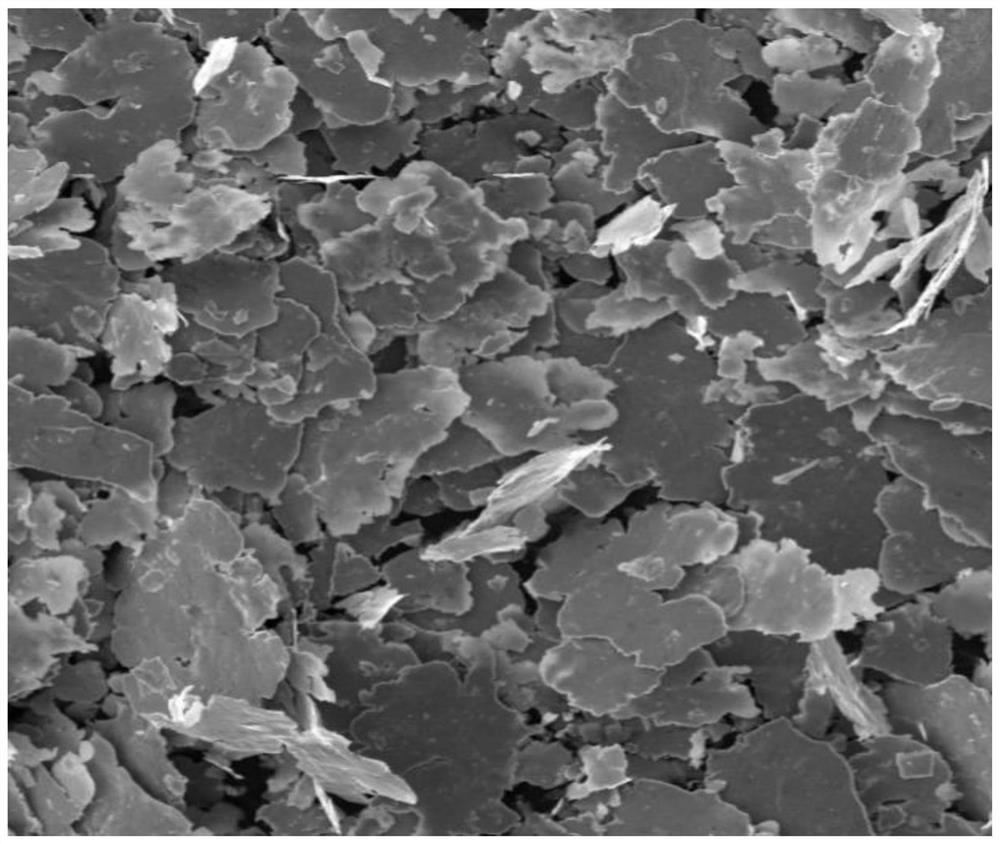

[0032] Step 2. FeSiAl flake powder preparation: FeSiAl alloy powder obtained in step 1 was wet ball milled at a rate of 800 rpm for 120 min in a high-energy ball mill to obtain scale-like FeSiAl flake powder with a thickness of 0.5 μm;

[0033] Step 3. Preparation of FeSiAl microwave-absorbing powder: The FeSiAl flake powder obtained in step 2 is first dried at a temperature of 100°C for 3 hours, and...

Embodiment 2

[0036] A FeSiAl sheet absorbing material

[0037] The FeSiAl sheet-shaped wave-absorbing material is made of FeSiAl wave-absorbing powder and colloid with a mass ratio of 10:0.85. The mass fractions of Fe, Si, and Al in the FeSiAl wave-absorbing powder are Fe10.0%, Si5.5%, Al84 .5%; Among them, the colloid is EPDM rubber.

[0038] The preparation steps are as follows:

[0039] Step 1. Preparation of FeSiAl alloy powder: After the mass fractions of Fe, Si, and Al are smelted, centrifuged, and ball milled, FeSiAl alloy powder with a particle size of 200 μm is obtained;

[0040] Step 2. FeSiAl flake powder preparation: FeSiAl alloy powder obtained in step 1 was wet ball milled at a rate of 1200 rpm for 60 min in a high-energy ball mill to obtain scale-like FeSiAl flake powder with a thickness of 1.0 μm;

[0041] Step 3. Preparation of FeSiAl microwave-absorbing powder: The FeSiAl flake powder obtained in step 2 is first dried at a temperature of 150°C for 2 hours, and then heat...

Embodiment 3

[0044] A FeSiAl sheet absorbing material

[0045] The FeSiAl sheet-shaped wave-absorbing material is made of FeSiAl wave-absorbing powder and colloid with a mass ratio of 10:0.65; the mass fractions of Fe, Si, and Al in the FeSiAl wave-absorbing powder are Fe9.7%, Si5.8%, Al84 .5%; Among them, the colloid is polyvinyl alcohol.

[0046] The preparation steps are as follows:

[0047] Step 1. Preparation of FeSiAl alloy powder: after the mass fractions of Fe, Si, and Al are smelted, centrifuged, and ball milled, FeSiAl alloy powder with a particle size of 150 μm is obtained;

[0048]Step 2. FeSiAl flake powder preparation: FeSiAl alloy powder obtained in step 1 was wet ball milled at a rate of 1000 rpm for 90 minutes in a high-energy ball mill to obtain scale-like FeSiAl flake powder with a thickness of 0.8 μm;

[0049] Step 3. Preparation of FeSiAl microwave-absorbing powder: The FeSiAl flake powder obtained in step 2 was first dried at 125°C for 2.5 hours, and then heated at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com