Composite absorbing material, preparation method and application thereof

A technology of composite absorbing materials and mixtures, which is applied in the field of absorbing materials to achieve excellent absorbing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

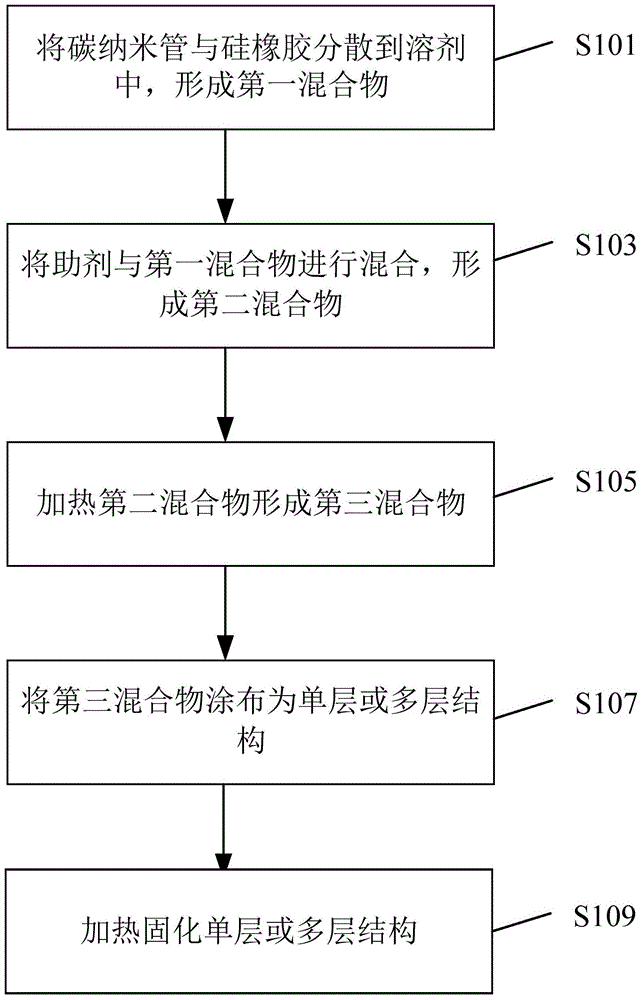

[0039] Preparation of Electrically Tunable Composite Absorbing Material

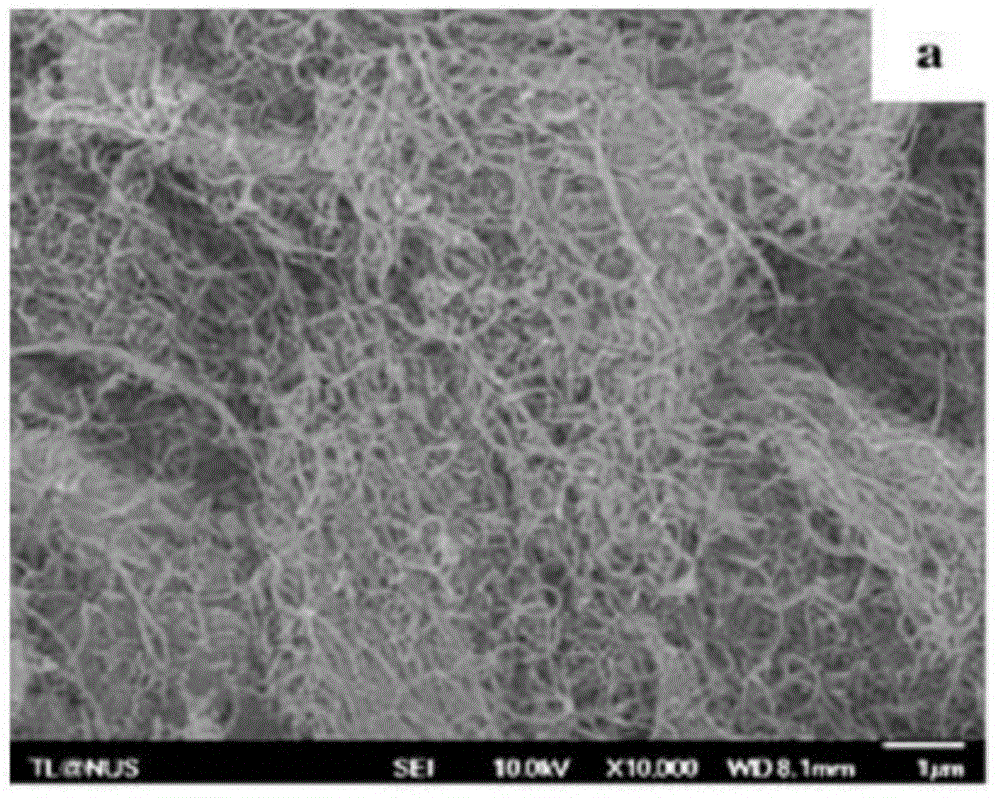

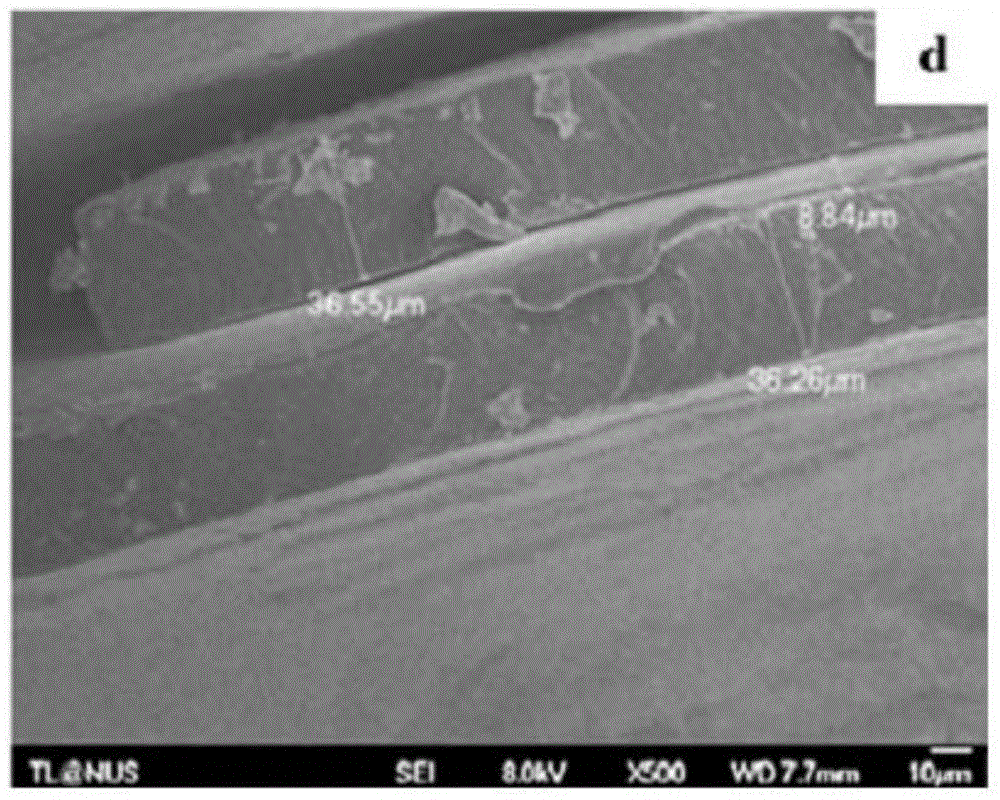

[0040] like figure 1 As shown in step S101, the silicone rubber and carbon nanotubes are dispersed into the organic solvent by an ultrasonic stirrer, thereby forming a first mixture. The organic solvent may include any solvent capable of dissolving silicone rubber, preferably, the organic solvent includes benzene, toluene and xylene. like figure 2 As shown, in the present invention, in order to make the final composite material have good wave-absorbing width and wave-absorbing ability, and have adjustable performance, the carbon nanotubes used are all multi-walled carbon nanotubes, and the carbon The average length of the nanotubes should be in the range of 40 microns to 80 microns, and the average diameter of the carbon nanotubes should be in the range of 5 microns to 20 microns. Preferably, the average length of the carbon nanotubes should be 50 microns, and the average diameter should be in the ra...

Embodiment 1

[0056] 98.75g silicone rubber (purchased from Dow Corning (DowCorningCooperation)) and 0.25g multi-walled carbon nanotubes (purchased from Chengdu Times Nano Chemical Company, Chinese Academy of Sciences) were dispersed in benzene solvent using an ultrasonic stirrer, wherein, the multi-walled carbon nanotubes The average length is 50 microns and the average diameter is 8 to 15 microns. The dispersion time was 20 minutes. Then 1 g of curing agent (purchased from Dow Corning (Dow Corning Cooperation)) was added to the above mixture and stirred for 10 minutes. The obtained mixed solution was heated in an oven at a temperature of 50° C. for 10 hours to remove the solvent benzene. The silicone rubber and curing agent used in the embodiment are all purchased from Dow Corning Corporation (DowCorningCooperation), and the brand is SYLGARD170; and this kind of silicone rubber is AB component silicone rubber, A component is silicone rubber, and B component is the The corresponding curi...

Embodiment 2

[0063] 96.5g silicone rubber (purchased from Dow Corning (DowCorningCooperation)) and 0.5g multi-walled carbon nanotubes (purchased from Chengdu Times Nanochemical Company, Chinese Academy of Sciences) were dispersed in toluene solvent using an ultrasonic stirrer, wherein, the multi-walled carbon nanotubes The average length is 50 microns and the average diameter is 8 to 15 microns. The dispersion time was 10 minutes. Then 2 g of curing agent (purchased from Dow Corning Cooperation) and 1 g of silicon dioxide were added to the above mixture and stirred for 15 minutes. The obtained mixed solution was heated in an oven at a temperature of 70° C. for 9 hours to remove the solvent toluene.

[0064] Subsequently, the solvent-removed mixture was coated on a glass substrate using a spin coater, wherein the rotation speed of the spin coater was 3000 rpm, and the coating thickness was 20 microns. Afterwards, the glass substrate and the coating were heated together in an oven at a tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com