Wave-absorbing material and preparation method thereof

A wave absorbing material and ball milling technology, applied in chemical instruments and methods, other chemical processes, electrical components, etc., can solve the problem that the wave absorbing material cannot meet the stealth technology at the same time, and achieve good wave absorbing effect, high magnetic permeability, The effect of improving the low frequency absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

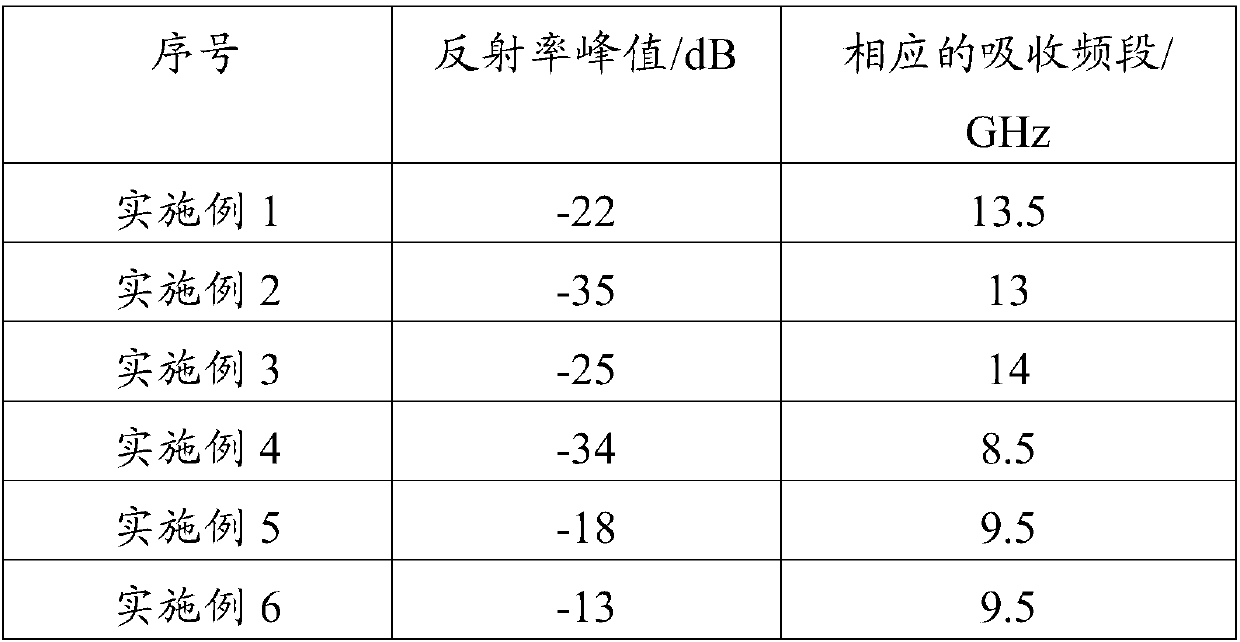

Examples

preparation example Construction

[0017] The preparation method of the wave-absorbing material provided by the invention comprises:

[0018] Add FeSiAl powder to the ball mill jar with a mass ratio of 1:4 to 10, and add an appropriate amount of C 1 -C 4 Alcohol solution, under the condition of rotating speed of 250-350rpm, ball mill for 24h-48h to obtain flake FeSiAl powder after ball milling. FeSiAl powder is oxidized, where, C 1 -C 4 The alcohol solution is selected from one or more combinations of methanol, ethanol, ethylene glycol, propanol, isopropanol and n-butanol.

[0019] According to the mass fraction of FeSiAl powder after ball milling in the mixture composed of FeSiAl powder after ball milling and carbonyl iron powder is 10% to 30%, weigh carbonyl iron powder and flake FeSiAl powder after ball milling and mix, and then according to the above The mass fraction of the mixture in both the above mixture and the binder is 70% to 80%, and the binder is weighed, and the above mixture is mixed with the...

Embodiment 1

[0022] Ball milling of FeSiAl powder: at a ball mass ratio of 1:4, add FeSiAl powder into the ball mill tank, and add an appropriate amount of absolute ethanol solution, and ball mill for 24 hours at a speed of 350rpm to obtain flake FeSiAl powder. Before ball milling, vacuumize the ball mill tank and pass nitrogen gas to remove the air in the tank and prevent the FeSiAl powder from being oxidized during the ball milling process.

[0023] Preparation of wave-absorbing material M1: Weigh 7g of ball-milled flaky FeSiAl powder and 63g of carbonyl iron powder, mix them evenly, add 30g of paraffin, and mix thoroughly to prepare a wave-absorbing material.

Embodiment 2

[0025] Ball milling of FeSiAl powder: Add FeSiAl powder to the ball mill tank at a mass ratio of 1:7, and add an appropriate amount of methanol solution, and ball mill for 48 hours at a speed of 250rpm to obtain flake FeSiAl powder. Vacuumize the ball mill tank and pass nitrogen gas to remove the air in the tank and prevent the FeSiAl powder from being oxidized during the ball milling process.

[0026] Preparation of wave-absorbing material M2: Weigh 21g of ball-milled flaky FeSiAl powder and 49g of carbonyl iron powder, mix well, add 30g of paraffin, and mix thoroughly to prepare wave-absorbing material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com