Multi-energy-field collaborative forming manufacturing method for high-performance bearing base body

A manufacturing method and multi-energy field technology, applied in the field of bearing manufacturing, can solve problems such as difficulty in ensuring the stability of the matrix structure, coarse grain structure of the matrix, and weakening of the strength and toughness of the matrix, so as to strengthen the weak area of structure performance and refine the grain size. Granular structure, the effect of reducing residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1 of the present invention takes a certain type of bearing base made of GCr15 material as an example, and provides a high-performance bearing base multi-energy field collaborative forming manufacturing method, which specifically includes the following steps:

[0045] S1, cold-rolled ring change pretreatment: adopt the cold-rolled ring method to realize the forming of the bearing matrix (the cold-rolled ring method can adopt a kind of cold-rolled forming method for an L-shaped cross-section automobile wheel bearing ring announced by Chinese patent CN103316926A), at an average feed Under the rolling condition of 1mm / s, the outer diameter of the base ring blank is expanded from 35mm to 48.5mm, and the bearing ring blank is subjected to room temperature deformation pretreatment, and the precise near-net shape of the raceway is realized during the process;

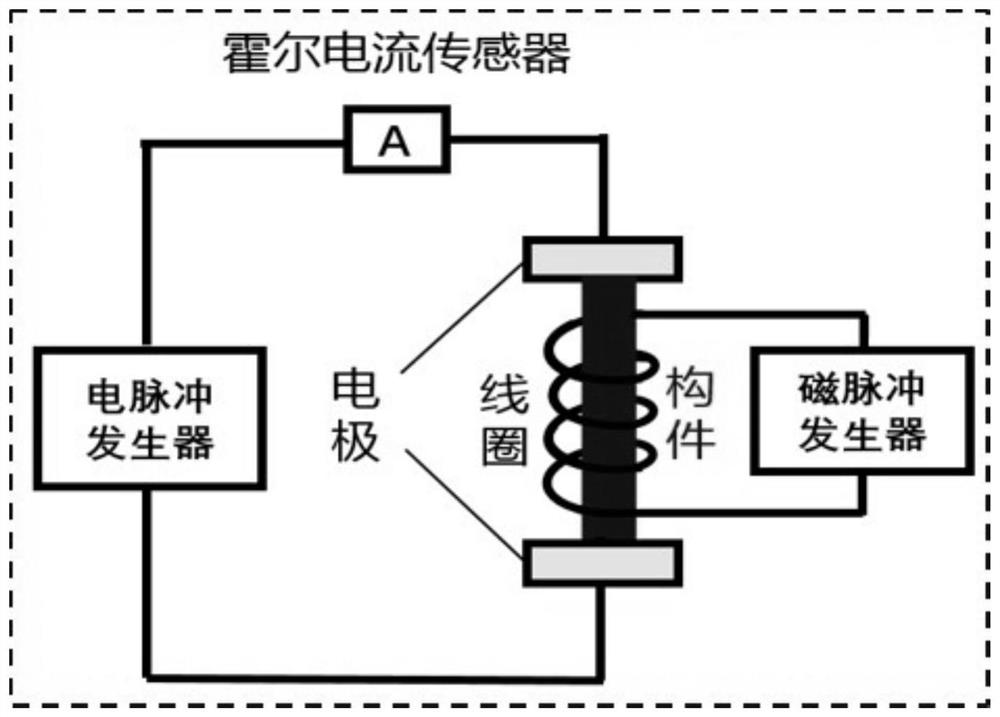

[0046] S2. Electromagnetic coupling auxiliary treatment: synchronously apply electric pulses and magnetic pu...

Embodiment 2

[0054] Embodiment 2 of the present invention takes a certain type of bearing base made of M50 material as an example, and provides a high-performance bearing base multi-energy field collaborative forming manufacturing method, which specifically includes the following steps:

[0055] S1. Cold-rolled ring change pretreatment: The bearing matrix is formed by cold-rolling ring method. Under the rolling condition of an average feed speed of 0.5mm / s, the outer diameter of the matrix ring blank is expanded from 100mm to 123.7mm. The bearing ring blank is subjected to deformation pretreatment at room temperature, and the precise near-net shape of the raceway is realized during the process;

[0056] S2. Electromagnetic coupling auxiliary treatment: synchronously apply electric pulses and magnetic pulses to the cold-rolled bearing substrate to control internal microscopic defects and residual stress respectively. In the pulse electric treatment process, the pulse current passing throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com