Oil-gas well oil pipe sand removing device and method

A technology for well tubing and sand cleaning, which is used in earth-moving drilling, wellbore/well components, etc., can solve the problems of safety and environmental protection risks, large operation area, large investment, etc., and achieves simple construction operation, reasonable structure and low investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

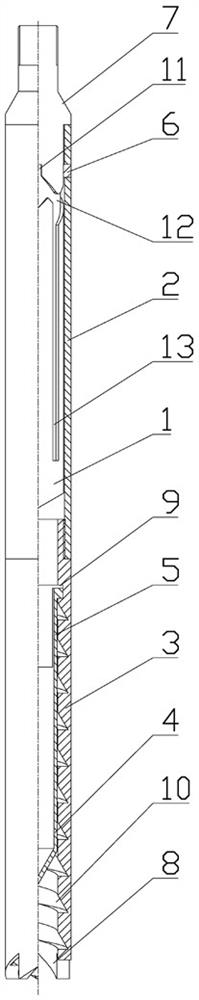

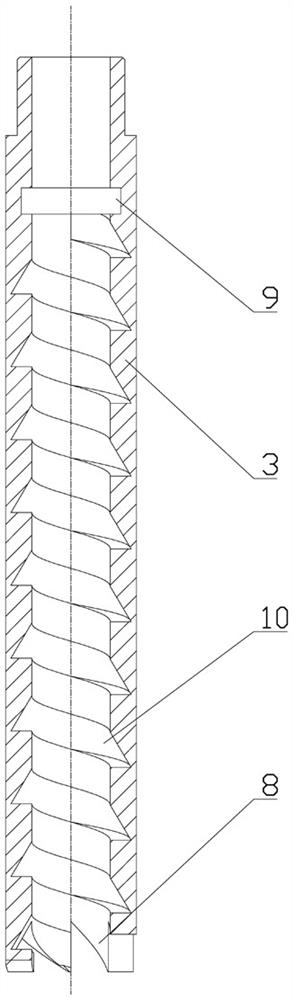

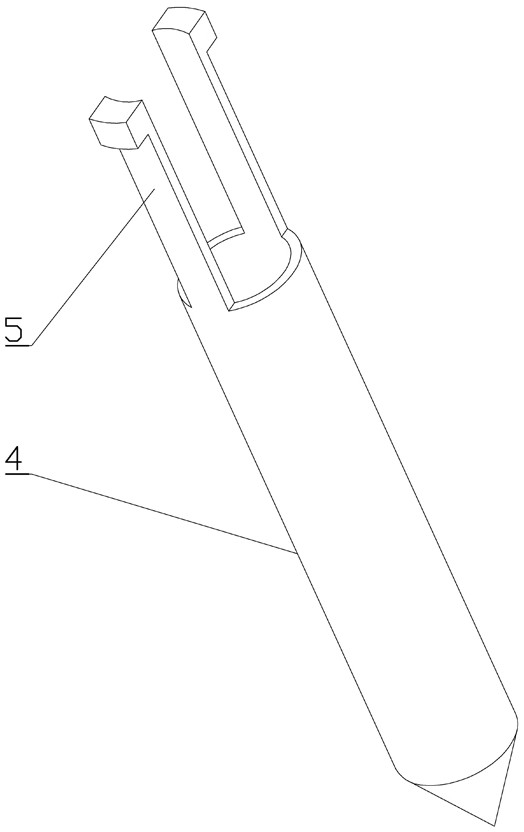

[0030] Embodiment one: as attached figure 1 , 2 , 3, 4, and 5, the oil and gas well tubing sand cleaning device includes a mandrel 1, a sheath 2, a sand taking barrel 3 and a sand fishing cup 4, and the sand taking barrel 3 is a hollow tubular structure arranged vertically, and the sand taking The inner side of the upper part of the cylinder 3 is provided with an inner ring groove 9, and the inner wall of the sand extraction cylinder 3 is provided with a spiral groove 10 whose upper end communicates with the inner ring groove 9 and the lower end extends to the lower end surface of the sand extraction cylinder 3, and the lower end surface of the sand extraction cylinder 3 is along the circumference. Several gnawing teeth 8 cutting along the helical direction of the spiral groove 10 are evenly distributed, and a sand-picking cup 4 with a cylindrical structure with an open upper end and a closed lower end is set inside the sand-taking cylinder 3. There are several earrings 5 w...

Embodiment 2

[0043] Embodiment two: as attached figure 1 , 5 Shown, a kind of sand cleaning method using above-mentioned oil and gas well tubing sand cleaning device comprises the following steps:

[0044] The first step is to detect the position of sand accumulation in the production string by using the stereotype device with the steel wire well testing vehicle, and calculate the amount of sand accumulation in the tubing according to the structure of the production string of the oil and gas well, so as to determine the number of operations;

[0045] The second step is to connect the upper part of the mandrel 1 of the oil and gas well tubing sand removal device with the corresponding weighting device, the upper part of the weighting device is connected to the wire rope cap, and the wire rope passes through the simple blowout preventer at the wellhead to connect with the wire rope cap;

[0046] The third step is to close the oil and gas well production string and connect the simple blowout...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap