Semiconductor packaging device, light-emitting device and manufacturing method of semiconductor integrated circuit

A technology for packaging devices and integrated circuits, which is applied in the direction of semiconductor devices, printed circuit manufacturing, and electrical component assembly of printed circuits, etc., can solve the problems of low reliability of semiconductor packaging devices and insufficient processing solutions, etc., so as to facilitate popularization and use, improve reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

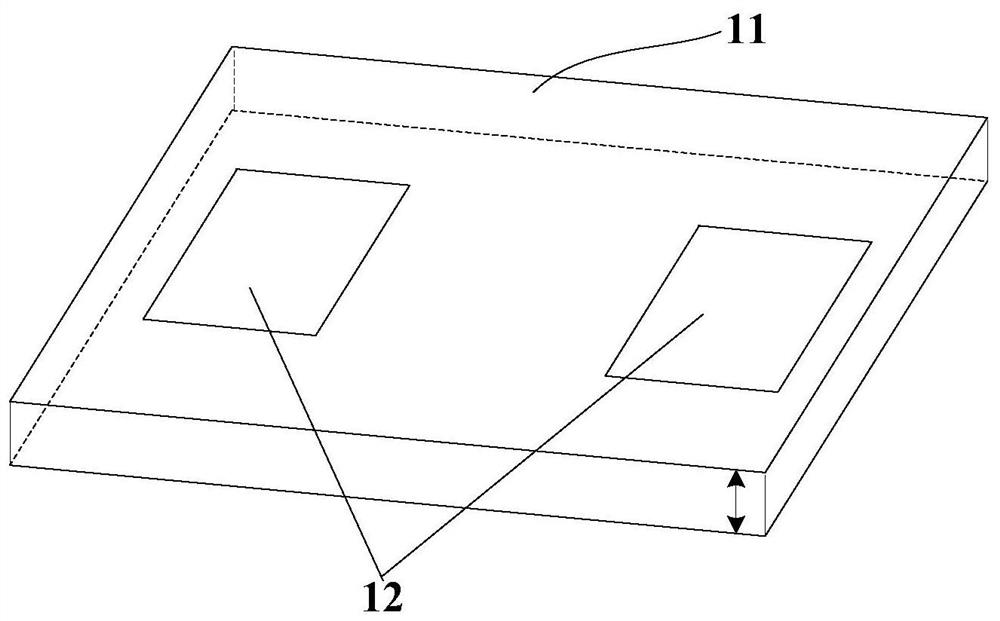

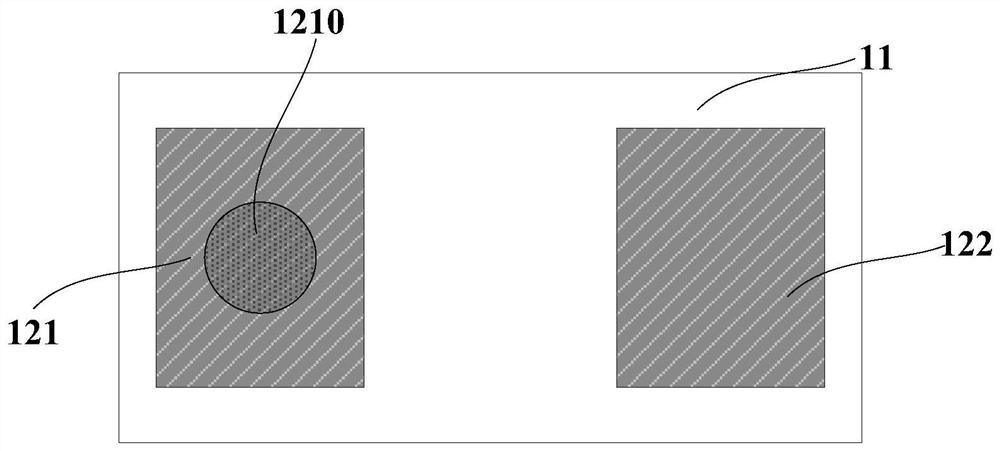

[0049] In order to solve the problem of insufficient air treatment solutions in the reflow soldering process in the prior art, resulting in low reliability of the semiconductor packaging device, this embodiment provides a semiconductor packaging device, the semiconductor packaging device includes a base, wherein, The base is composed of a non-metallic substrate and a metal pad, the metal pad penetrates the non-metallic substrate along the height direction, and at least one vent hole is provided on the metal pad, and the vent hole is used to discharge the air inside the semiconductor packaging device.

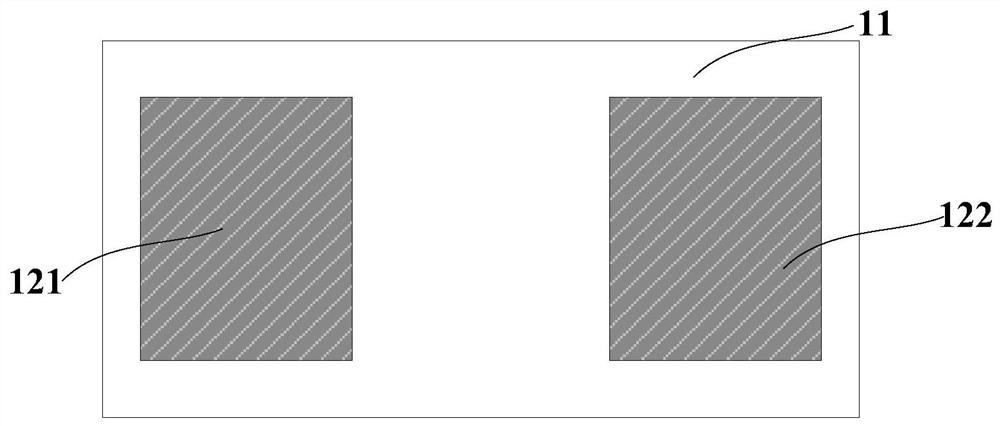

[0050] In this example, see Picture 1-1 , Figure 1-2 As shown, the metal pad 12 includes a first metal pad 121 and a second metal pad 122, and the first metal pad 121 and the second metal pad 122 respectively pass through the non-metal On the substrate 11 , the first metal pad 121 is isolated from the second metal pad 122 by the non-metallic substrate 11 .

[0051] The first ...

Embodiment 2

[0085] In order to solve the problem of insufficient air treatment solutions in the reflow soldering process in the prior art, resulting in low reliability of semiconductor packaging devices, this embodiment provides a method for manufacturing a semiconductor integrated circuit. Please refer to Figure 4 As shown, the manufacturing method of the semiconductor integrated circuit includes:

[0086] S401: Use the steel mesh as a mold to print soldering material on the PCB circuit board;

[0087] S402: Attach the semiconductor package device with vent holes on the pad to the corresponding soldering material position on the PCB circuit board;

[0088] S403: Place the PCB circuit board on which the semiconductor packaging device has been attached in S402 in the reflow furnace for reflow heating. During the heating process of the reflow furnace, the air inside the semiconductor packaging device is discharged from the vent hole of the pad at the bottom of the bowl, and at the same tim...

Embodiment 3

[0121] This embodiment also provides a light emitting device, which includes the semiconductor packaging device exemplified in the above embodiments. The light emitting device in this embodiment may be an illuminating device, a light signal indicating device, a supplementary light device or a backlight device, and the like. When it is a lighting device, it can specifically be a lighting device used in various fields, such as desk lamps, fluorescent lamps, ceiling lamps, downlights, street lights, projection lights, etc. in daily life, and for example, high beams and low beams in cars Lamps, ambient lights, etc., such as surgical lights, low-electromagnetic lighting, and lighting for various medical instruments, and various colored lights, landscape lighting, advertising lights, etc. in the field of decorative lighting; for In the case of an optical signal indicating device, it may specifically be an optical signal indicating device applied in various fields, such as signal ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com