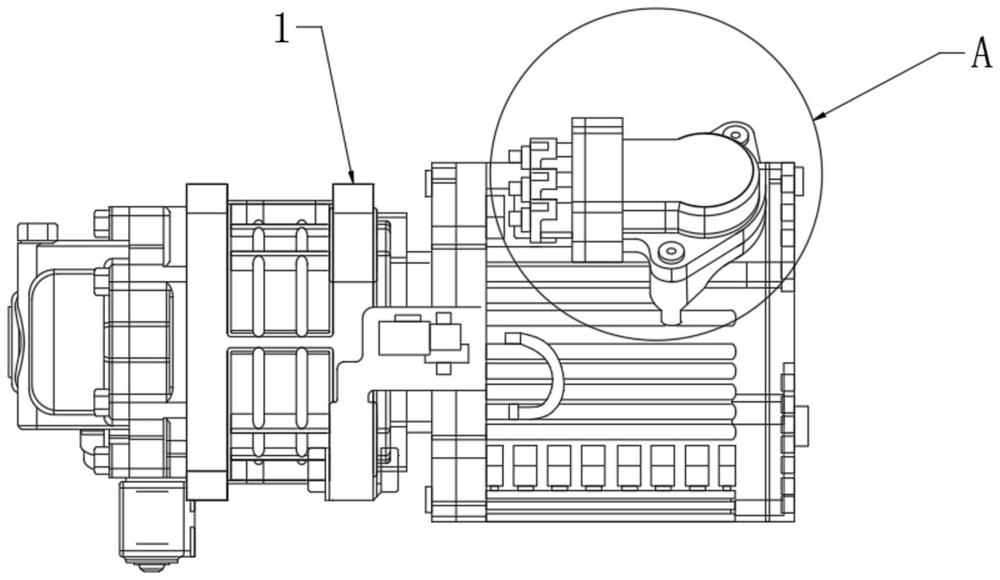

Integrated hydrogen circulating pump in fuel cell system

A fuel cell system and circulating pump technology, applied to fuel cells, fuel cell additives, electrical components, etc., can solve problems such as rotor misalignment, leakage of hydrogen circulating pump, shortening the service life of hydrogen circulating pump, etc. non-concentric effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

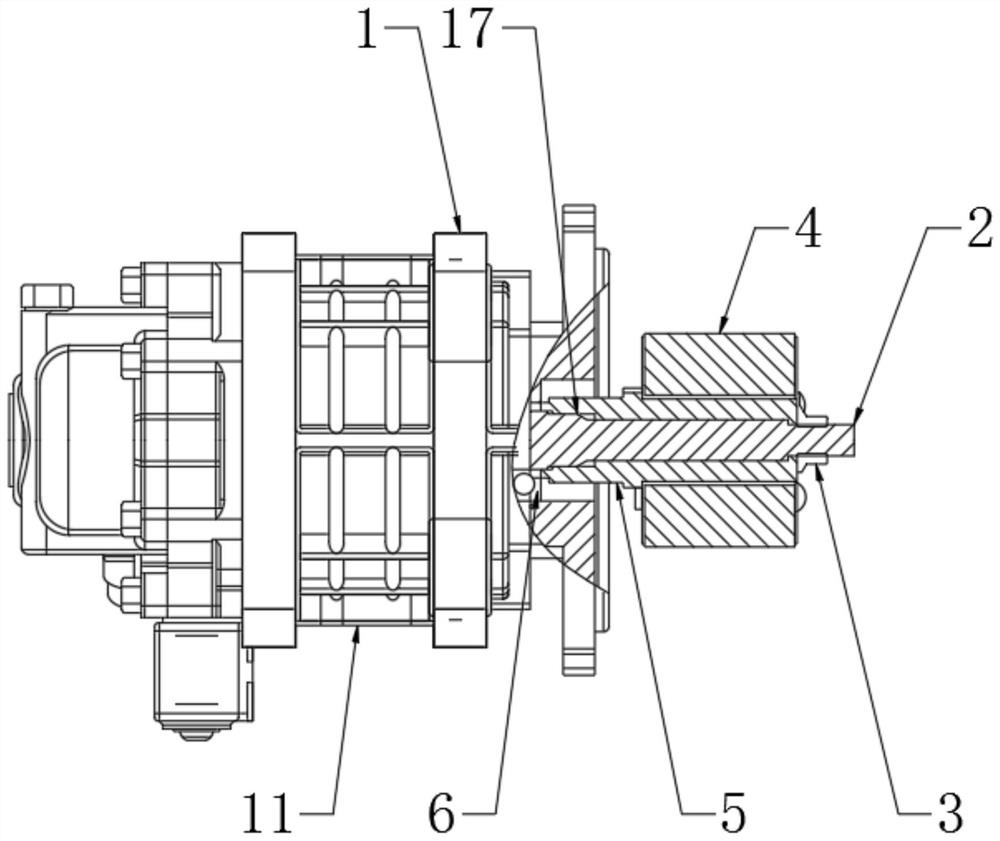

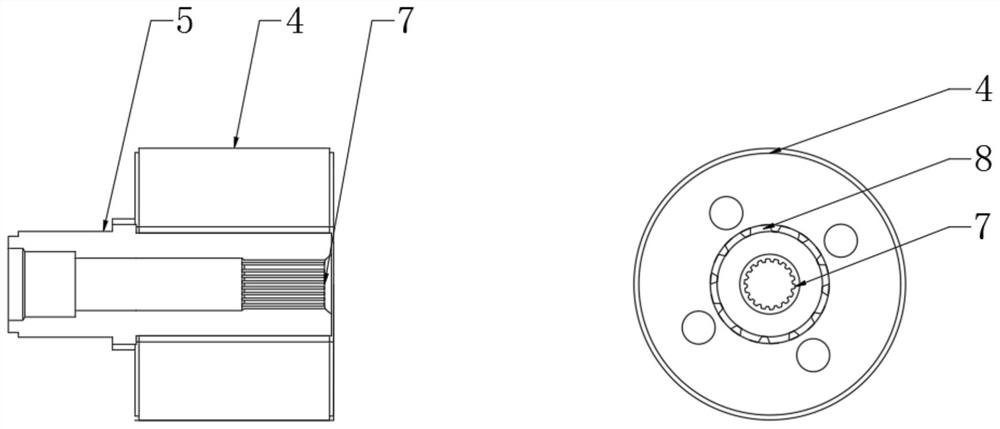

[0028] Solve the non-concentricity problem between the permanent magnet synchronous motor rotor assembly and the shaft 2 by detecting the amount of rotor runout after installation; pass the water injection and freezing test on the casing of the hydrogen circulation pump by simulating the operating conditions, and it can start normally under low temperature conditions; through the integration The motor part of the hydrogen circulation pump is tested for airtight helium leakage, so that the sealing problem of the motor is solved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com