Intelligent agricultural cultivation system

An agricultural and intelligent technology, applied in agriculture, agricultural gas emission reduction, cultivation, etc., can solve problems such as inability to cultivate seeds, and achieve the effect of achieving healthy growth and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

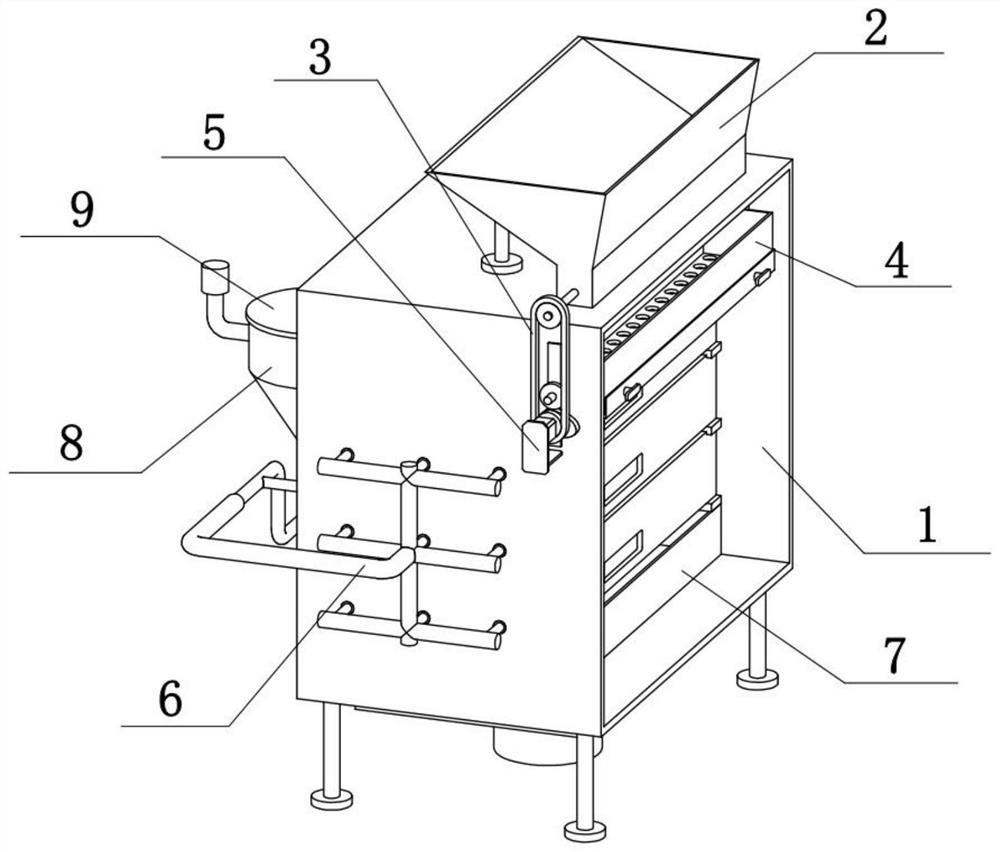

[0035] Combine below Figure 1-12 Describe this embodiment, an intelligent agricultural cultivation system, including a carrying component 1, a stocking component 2, a feeding component 3, a sorting component 4, a vibrating component 5, a spraying component 6, a recycling component 7, a supply component 8 and a mixing component 9 , the storage assembly 2 is fixedly connected to the carrying assembly 1, the unloading assembly 3 is rotatably connected to the storage assembly 2, the sorting assembly 4 is slidingly connected to the carrying assembly 1, and the vibration assembly 5 is provided with two, two vibrating Components 5 are respectively fixedly connected to the front and rear sides of the bearing component 1, and the two vibration components 5 are in line contact with the sorting component 4. The blanking component 3 is fixedly connected to the vibration component 5 at the front end. Two spraying assemblies 6 are respectively fixedly connected to the front and rear sides ...

specific Embodiment approach 2

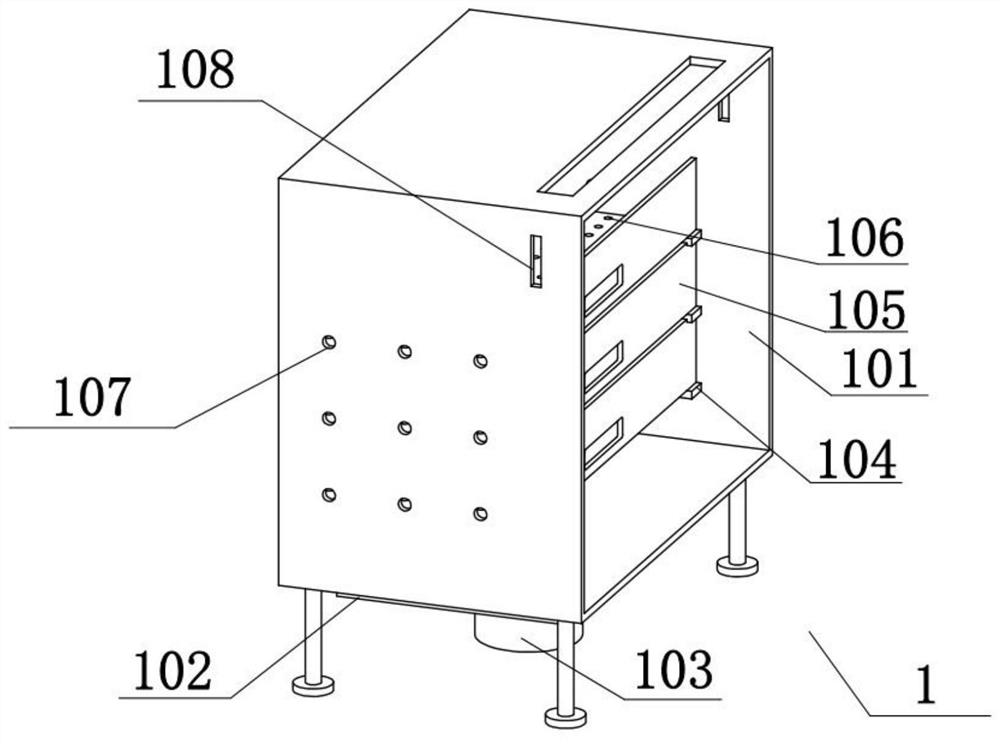

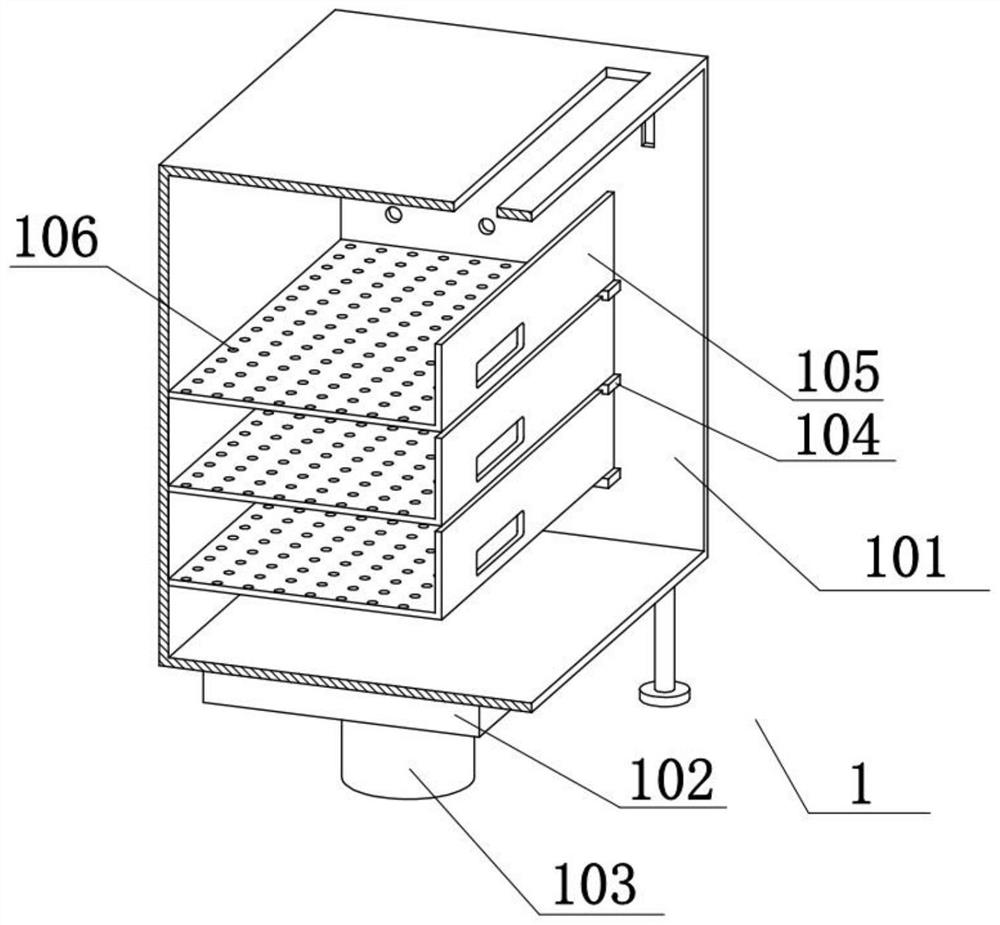

[0038] Combine below Figure 1-12 To illustrate this embodiment, the carrying assembly 1 includes an incubator 101, a heat uniform box 102, a heating furnace 103, a slideway 104, a graded cultivation tank 105, a penetration hole 106, a spray hole 107 and a chute 108, and the lower end of the incubator 101 The heat uniform box 102 is fixedly connected, and the heating furnace 103 is fixedly connected to the heat uniform box 102. The left and right sides of the incubator 101 are provided with slideways 104, and multiple graded cultivation tanks 105 are respectively slidably connected to multiple slideways 104. A plurality of permeation holes 106 are evenly distributed on a plurality of graded cultivation tanks 105, a plurality of spray holes 107 are evenly distributed on the front and rear sides of the cultivation box 101, and chutes 108 are arranged on the front and rear sides of the cultivation box 101.

specific Embodiment approach 3

[0040] Combine below Figure 1-12 To illustrate this embodiment, the material storage assembly 2 includes a storage hopper 201, a lower hopper 202 and a hopper leg 203, the storage hopper 201 is fixedly connected to the lower hopper 202, and the lower hopper 202 is fixedly connected to the upper end of the incubator 101, A plurality of hopper legs 203 are fixedly connected to the storage hopper 201 , and the plurality of hopper legs 203 are fixedly connected to the incubator 101 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com