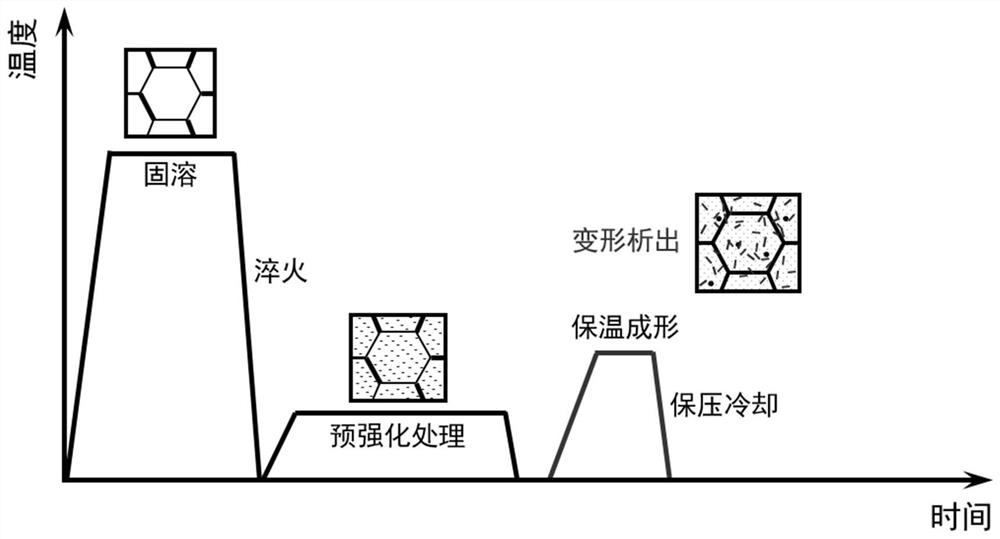

A kind of aluminum alloy pre-strengthening hot stamping forming method

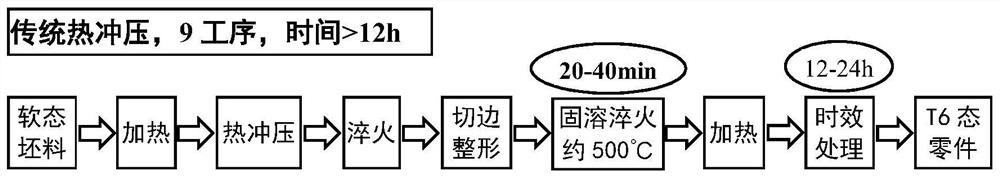

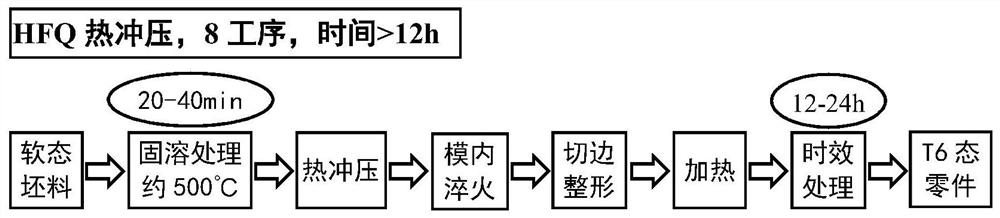

A technology of hot stamping and aluminum alloy, which is applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of complicated procedures, unfavorable efficiency, and high equipment cost, so as to reduce energy consumption, improve production efficiency, and low equipment cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Using 2024 aluminum alloy as a blank, an aluminum alloy pre-strengthening hot stamping forming method includes the following steps:

[0037] (1) Place the 2024 aluminum alloy billet in a resistance furnace and heat it to 487-499°C and keep it warm for 30 minutes to obtain a W-state aluminum alloy plate;

[0038] (2) Pre-strengthen the W-state aluminum alloy plate within 10 minutes, that is, heat it to 50°C and keep it warm for 24 hours to obtain a hot stamping blank;

[0039] (3) Transfer the blank to the hot stamping production line, heat it to 270°C, and keep it warm for 30 seconds;

[0040] (4) The heated billet is quickly transferred to a water-cooled mold within 7 seconds for hot stamping and pressure-holding and cooling in the mold to obtain the final product without subsequent aging heat treatment.

[0041] Cut tensile samples from the parts after stamping and perform uniaxial tensile test to test their mechanical properties after forming. Taking the average val...

Embodiment 2

[0043] Using 2024 aluminum alloy as a blank, an aluminum alloy pre-strengthening hot stamping forming method includes the following steps:

[0044] (1) Place the 2024 aluminum alloy billet in a resistance furnace and heat it to 487-499°C and keep it warm for 30 minutes to obtain a W-state aluminum alloy plate;

[0045] (2) Pre-strengthen the W-state aluminum alloy plate within 10 minutes, that is, heat it to 100°C and keep it warm for 1 hour to obtain a hot stamping blank;

[0046] (3) Transfer the blank to the hot stamping production line, heat it to 230°C, and keep it warm for 5 minutes;

[0047] (4) The heated billet is quickly transferred to a water-cooled mold within 7 seconds for hot stamping and pressure-holding and cooling in the mold to obtain the final product without subsequent aging heat treatment.

[0048] Cut tensile samples from the parts after stamping and perform unidirectional tensile test to test their mechanical properties after forming. Taking the average...

Embodiment 3

[0050] Using 2024 aluminum alloy as a blank, an aluminum alloy pre-strengthening hot stamping forming method includes the following steps:

[0051] (1) Place the 2024 aluminum alloy billet in a resistance furnace and heat it to 487-499°C and keep it warm for 30 minutes to obtain a W-state aluminum alloy plate;

[0052] (2) Pre-strengthen the W-state aluminum alloy plate within 10 minutes, that is, heat it to 75°C and keep it warm for 12 hours to obtain a hot stamping blank;

[0053] (3) Transfer the blank to the hot stamping production line, heat it to 250°C, and keep it warm for 3 minutes;

[0054] (4) The heated billet is quickly transferred to a water-cooled mold within 7 seconds for hot stamping and pressure-holding and cooling in the mold to obtain the final product without subsequent aging heat treatment.

[0055] Cut tensile samples from the parts after stamping and perform uniaxial tensile test to test their mechanical properties after forming. Taking the average valu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com