Regeneration process of resin sand for casting

A casting resin and process technology, which is applied in the field of casting resin sand regeneration technology, can solve the problems of poor quality of recycled sand, and achieve the effects of ensuring emission, improving heat treatment effect, and low emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

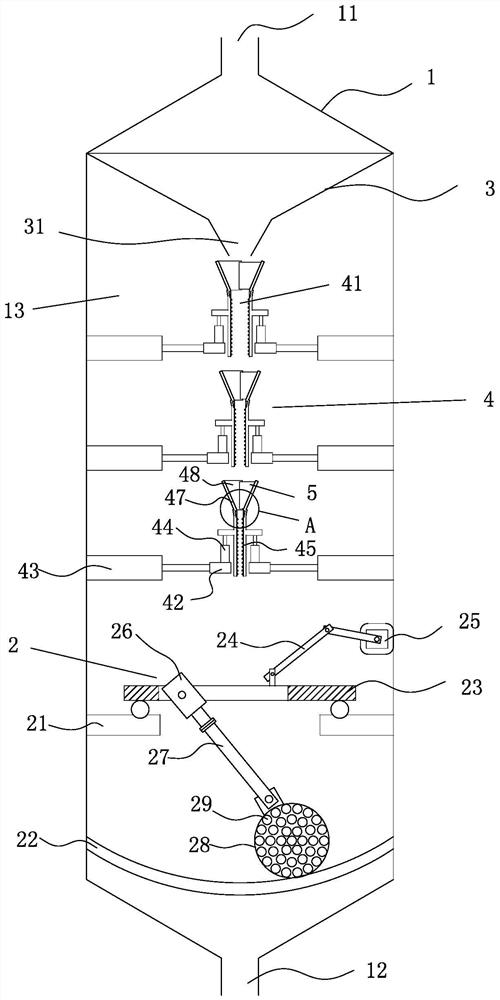

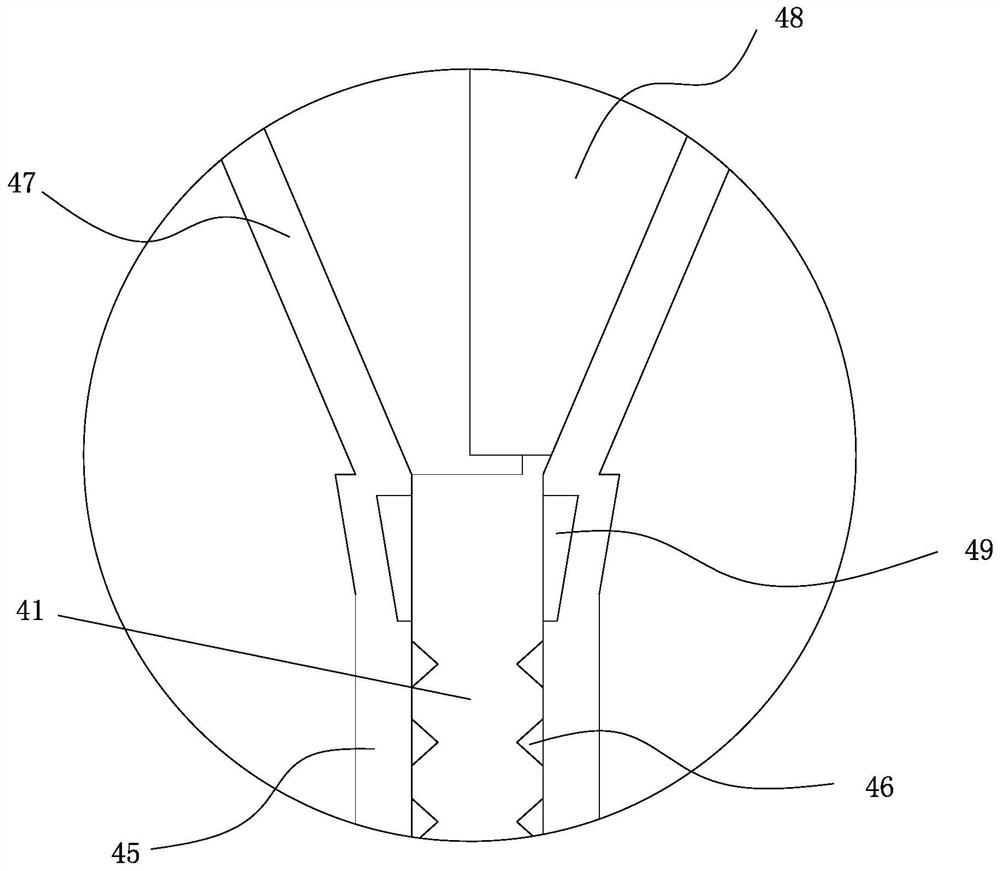

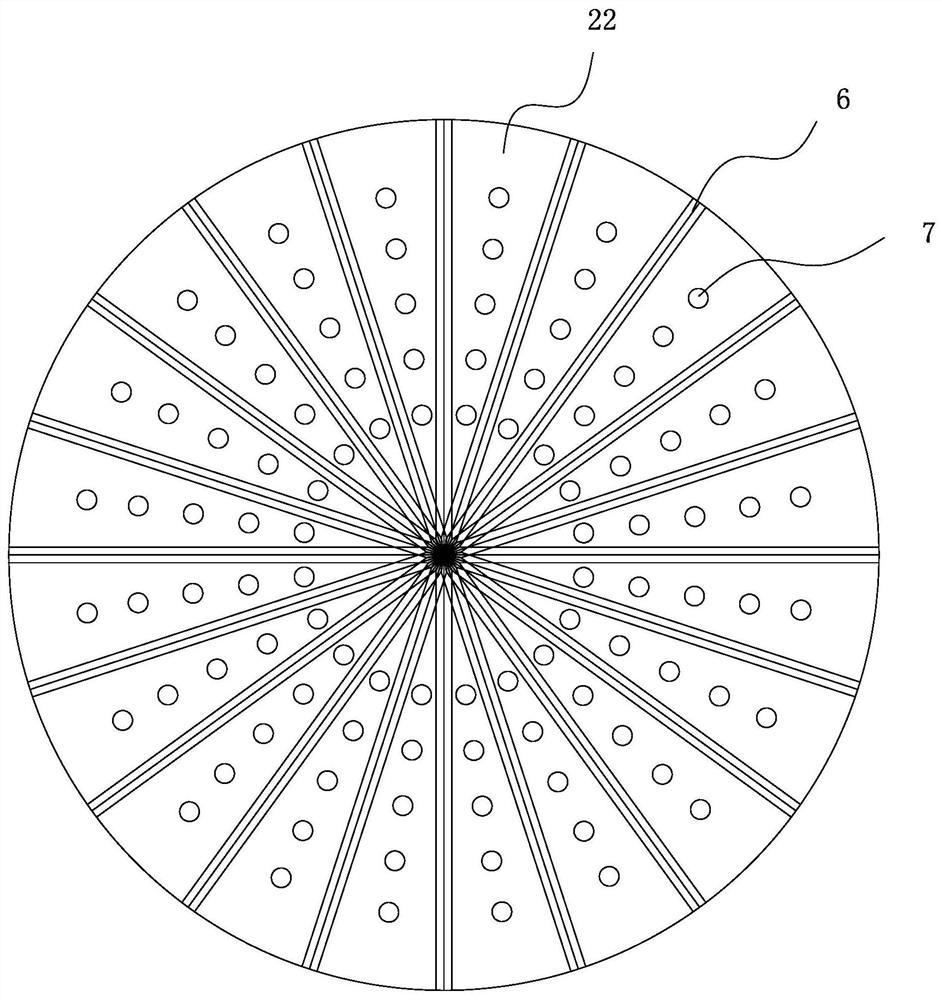

[0021] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

[0022] Embodiments of the invention are:

[0023] A resin sand regeneration process for foundry, comprising the following steps:

[0024] 1) molding sand crushing;

[0025] 2) Flatten the old sand that has been crushed to form granules on the conveyor belt on the conveying device and transport it through a magnetic field with a magnetic field strength of 1.2T;

[0026] 3) putting the old sand treated in step 2) into a solution with a pH value of 4.7 for soaking and ultrasonic treatment;

[0027] 4) putting the old sand treated in step 3) into a roasting furnace with a temperature of 870° C. for 4 hours;

[0028] 5) After gradually lowering the temperature of the roasting furnace to 250°C, take out the old sand and soak it in the cooling liquid for rapid cooling, and then put it into the potassium hydroxide solution;

[0029] 6) Take out the old s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com