High-thermal-conductivity high-strength copper alloy heat conduction pipe for electronic products

A technology with high thermal conductivity and electronic products. It is applied in the fields of modification through conduction and heat transfer, electrical components, and structural parts of electrical equipment. and other issues, to achieve the effect of good thermal conductivity, good plasticity, and efficient heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

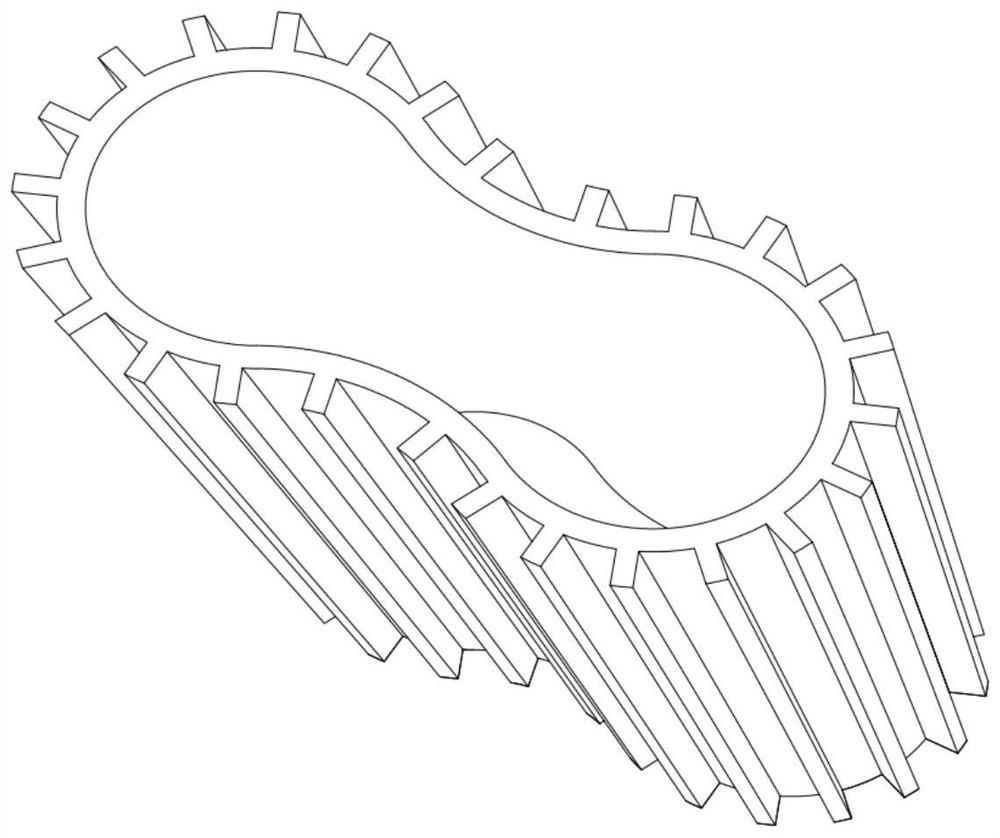

Image

Examples

Embodiment 1

[0038] A high-thermal-conductivity high-strength copper alloy heat pipe for electronic products, comprising the following components by mass percentage:

[0039] Cr, 0.5%;

[0040] Ni, 0.26%;

[0041] Zr, 0.05%;

[0042] Nb, 0.03%;

[0043] Mg, 0.06%;

[0044] Fe, 0.04%;

[0045] Sn, 0.01%;

[0046] Ag, 0.01%;

[0047] Rh, 0.05%;

[0048] Ce, 0.04%;

[0049] P, 0.02%;

[0050] Cu, balance.

[0051] In this embodiment, the heat pipe is prepared by smelting, casting, extrusion, water cooling, and aging treatment. Specifically, the ingredients are prepared according to the ratio of each component. After the ingredients are melted and cast at a high temperature, a long billet with a circular cross-section is formed. The billet is extruded in a mold to form a pipe with a specific cross-sectional shape. The finished heat pipe is obtained through water cooling and aging treatment.

[0052] In this embodiment, the melting temperature is within the range of 1180°C; the extr...

Embodiment 2

[0055] A high-strength copper alloy heat pipe with high thermal conductivity for electronic products, comprising the following components by mass percentage:

[0056] Cr, 0.8%;

[0057] Ni, 0.2%;

[0058] Zr, 0.4%;

[0059] Nb, 0.05%;

[0060] Mg, 0.07%;

[0061] Fe, 0.08%;

[0062] Sn, 0.03%;

[0063] Ag, 0.05%;

[0064] Rh, 0.01%;

[0065] Ce, 0.12%;

[0066] P, 0.03%;

[0067] Cu, balance.

[0068] In this embodiment, the heat pipe is prepared by smelting, casting, extrusion, water cooling, and aging treatment. Specifically, the ingredients are prepared according to the ratio of each component. After the ingredients are melted and cast at a high temperature, a long billet with a circular cross-section is formed. The billet is extruded in a mold to form a pipe with a specific cross-sectional shape. The finished heat pipe is obtained through water cooling and aging treatment.

[0069] In this embodiment, the melting temperature is within the range of 1230°C; the e...

Embodiment 3

[0072] A high-strength copper alloy heat pipe with high thermal conductivity for electronic products, comprising the following components by mass percentage:

[0073] Cr, 0.65%;

[0074] Ni, 0.23%;

[0075] Zr, 0.24%;

[0076] Nb, 0.042%;

[0077] Mg, 0.06%;

[0078] Fe, 0.05%;

[0079] Sn, 0.026%;

[0080] Ag, 0.02%;

[0081] Rh, 0.04%;

[0082] Ce, 0.07%;

[0083] P, 0.02%;

[0084] Cu, balance.

[0085] In this embodiment, the heat pipe is prepared by smelting, casting, extrusion, water cooling, and aging treatment. Specifically, the ingredients are prepared according to the ratio of each component. After the ingredients are melted and cast at a high temperature, a long billet with a circular cross-section is formed. The billet is extruded in a mold to form a pipe with a specific cross-sectional shape. The finished heat pipe is obtained through water cooling and aging treatment.

[0086] In this embodiment, the melting temperature is 1210°C; the extrusion temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat transfer coefficient | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com