Fructus cinnamomi green tea processing method

A processing method, the technology of Guiding green tea, which is applied in the direction of tea treatment before extraction, can solve the problems of unobvious product characteristics, high production cost, and high labor intensity, so as to improve the taste of tea, reduce the rate of broken leaves of tea, and strengthen the tea. The effect of heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The processing method of the Guiding green tea of the present invention comprises the steps:

[0022] 1) Green spreading: Evenly spread the fresh leaves of Guiding tea picked that day in the withering tank for natural green spreading. The thickness of spreading is 1-2cm, and the spreading time is 2-6h. Rain leaves can be properly blown or extended. During the cool time, the water content of fresh leaves is about 70% after spreading green. The specific performance is: the fresh leaves are stretched, energetic, shiny, moderately soft and hard, and should be stirred as little as possible during green spreading.

[0023] 2) Finishing: Send green leaves to the drum electric heating machine through the conveyor belt or fresh leaf conveyor. The temperature of the drum is set at 300-350°C, and the killing time is set at 60-80 seconds. The standard is that the leaves are dry and soft, and the leaves White bubbles appear on the edge, no water overflows after kneading with hands...

Embodiment 1

[0029] During the production process of the fresh leaves of Guiding tea, after the greening is done, it is naturally spread to cool, and then it is rolled and dried, and the rest of the conditions are the same as in Example 1.

Embodiment 2

[0031] In the production process of the fresh leaves of Guiding tea, after the greening, resurgence and sweeping up and down are adopted, and there is no high-humidity air auxiliary cooling treatment, and the rest of the conditions are the same as in Example 1.

[0032] Effect verification.

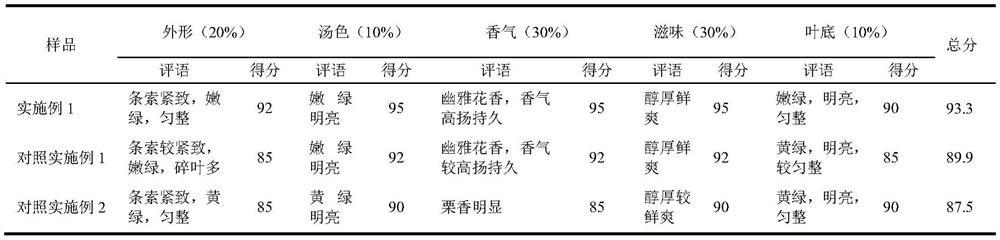

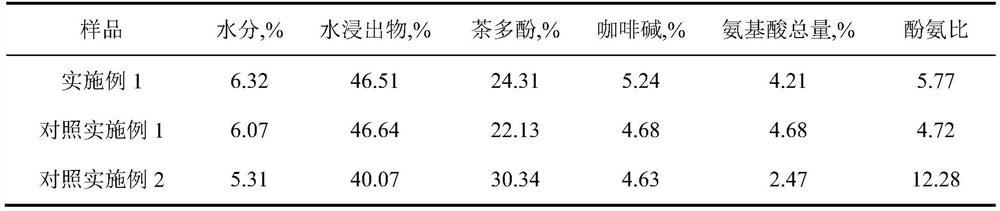

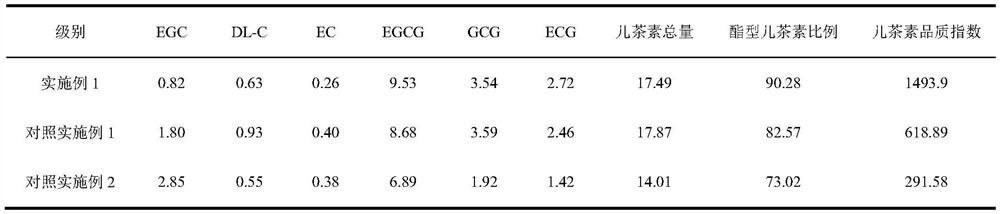

[0033] The products obtained in Example 1, Comparative Example 1, and Comparative Example 2 were subjected to sensory evaluation, quality testing of main components, and analysis of catechin composition. The results are shown in Table 1, Table 2, and Table 3.

[0034] Table 1 Sensory evaluation results

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com