Esterification reaction kettle with efficient heat exchange function

A technology of esterification reaction kettle and function, applied in the field of esterification reaction kettle, can solve the problem of low heating efficiency, achieve the effect of increasing the heating area, improving heat transfer efficiency, and promoting heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

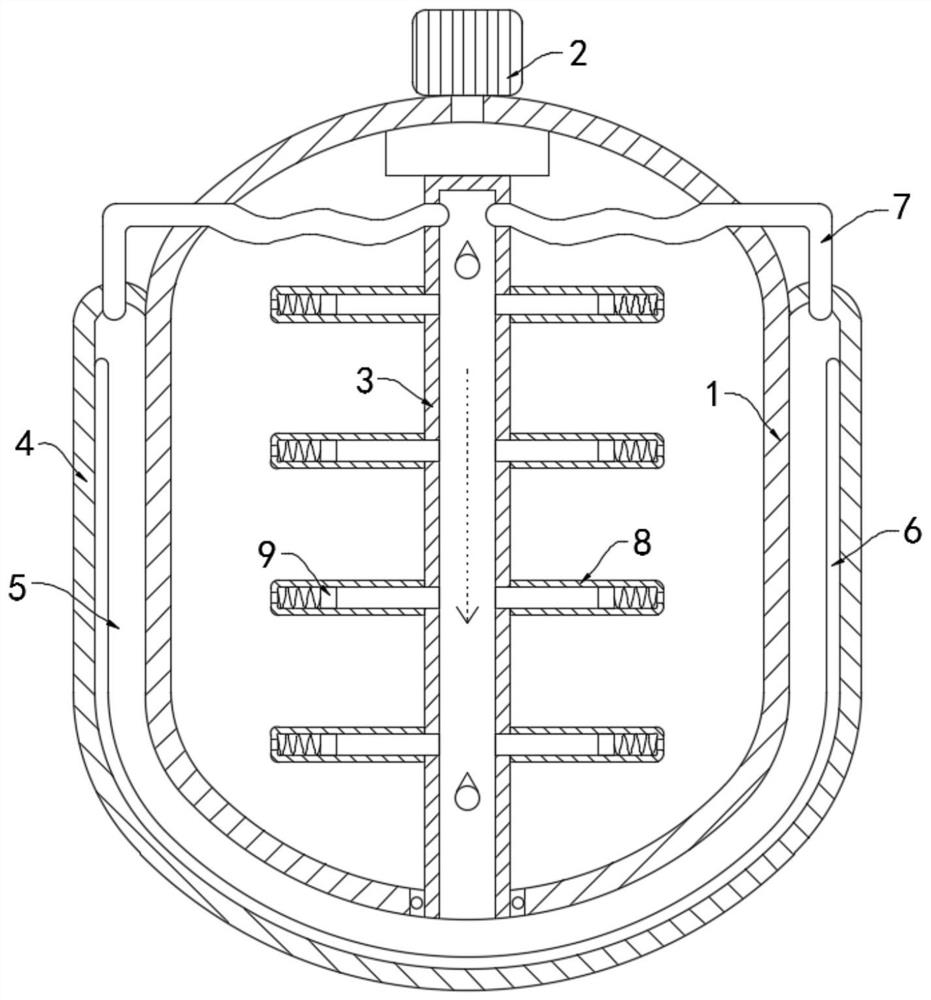

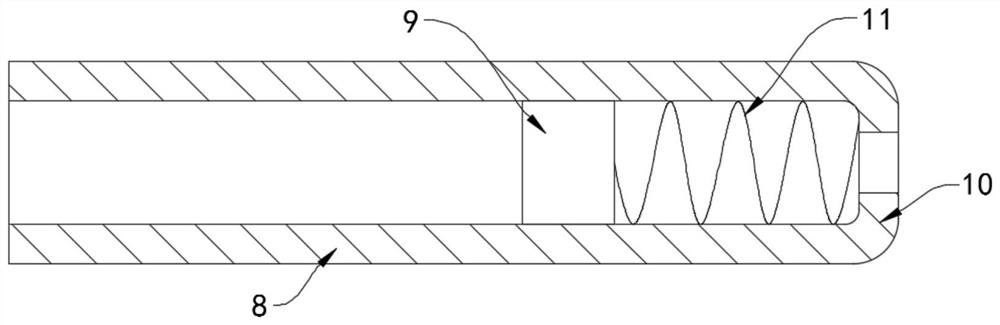

[0025] like Figure 1-2 As shown, an esterification reaction kettle with high-efficiency heat exchange function includes a vertically arranged kettle body 1 and a servo motor 2. The model of the servo motor 2 is TJS-11KW, and the servo motor 2 is installed on the upper end of the kettle body 1.

[0026] The kettle body 1 is provided with a main pipe 3 arranged along its axis. The upper end of the main pipe 3 is rotationally connected with the inner top surface of the kettle body 1 through a bearing. The input end of the servo motor 2 extends into the kettle body 1 and is fixed to the upper end of the main pipe 3. Connected, under the drive of the servo motor 2, the main pipe 3 will continuously rotate forward and reverse alternately.

[0027] The outer fixed sleeve of the kettle body 1 is provided with an insulating layer 4, and a sealed heating chamber 5 is formed between the insulating layer 4 and the outer wall of the kettle body 1. The lower side wall is sealed and rotate...

Embodiment 2

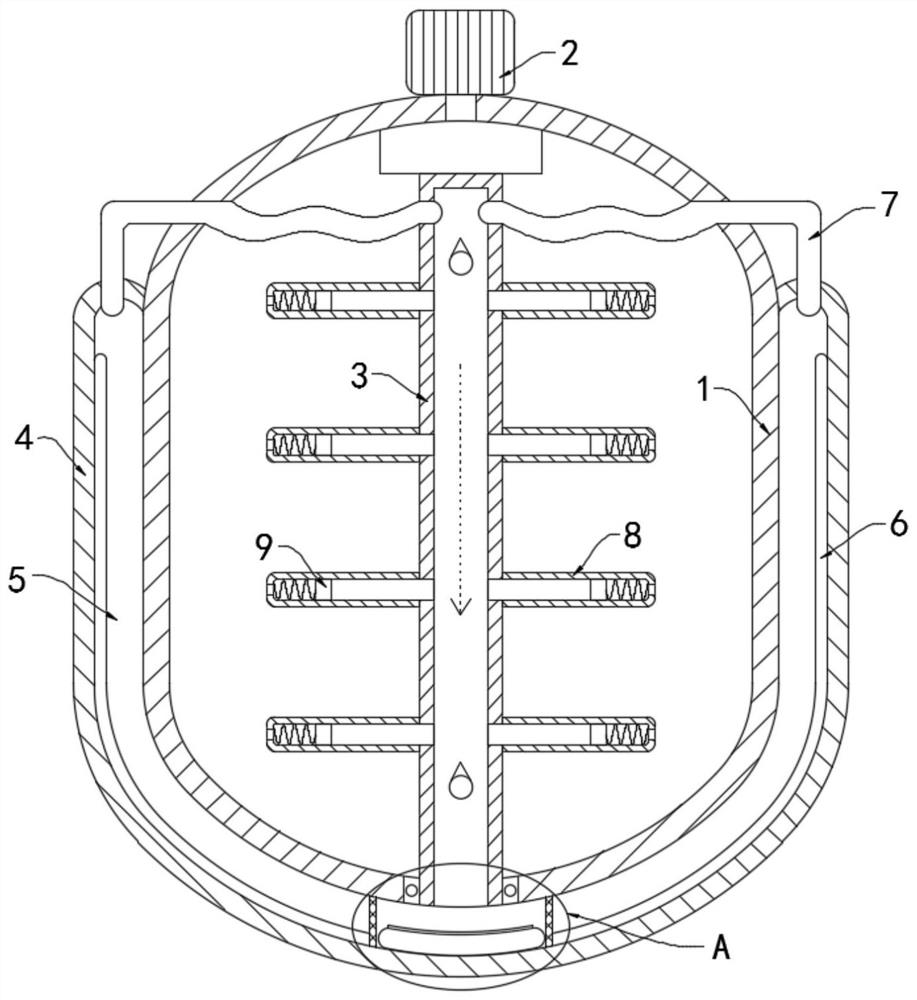

[0038] like Figure 3-4 As shown, the difference between this embodiment and Embodiment 1 is that two screen plates 12 that are all vertically arranged are fixedly connected between the lower side wall of the kettle body 1 and the insulation layer 4, and the two screen plates 12 slide Connected with a magnet block 13, the mesh plate 12 can limit the sliding of the magnet block 13, the magnet block 13 is located directly below the lower port of the main pipe 3, and the Curie point of the magnet block 13 is not higher than the maximum temperature required for the esterification reaction .

[0039] Be positioned at the still body 1 side wall of magnet block 13 upper ends and be fixedly embedded with the permanent magnet block (not shown) of homopolar repelling mutually, under normal circumstances magnet block 13 and permanent magnet block homopolar repel mutually, when temperature is high When the Curie point of the magnet block 13 causes degaussing, the magnet block 13 will be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com