Novel connecting shaft bracket for short-stress rolling mill

A short-stress rolling mill and shaft-connecting bracket technology is applied in the driving device, rolling mill control device, metal rolling and other directions for metal rolling mills, which can solve the problem of reducing hourly output and product yield, automatic control, and short-stress rolling mill opening. It can reduce the accidents of process equipment and product quality, facilitate adjustment, and improve the hourly output and product yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

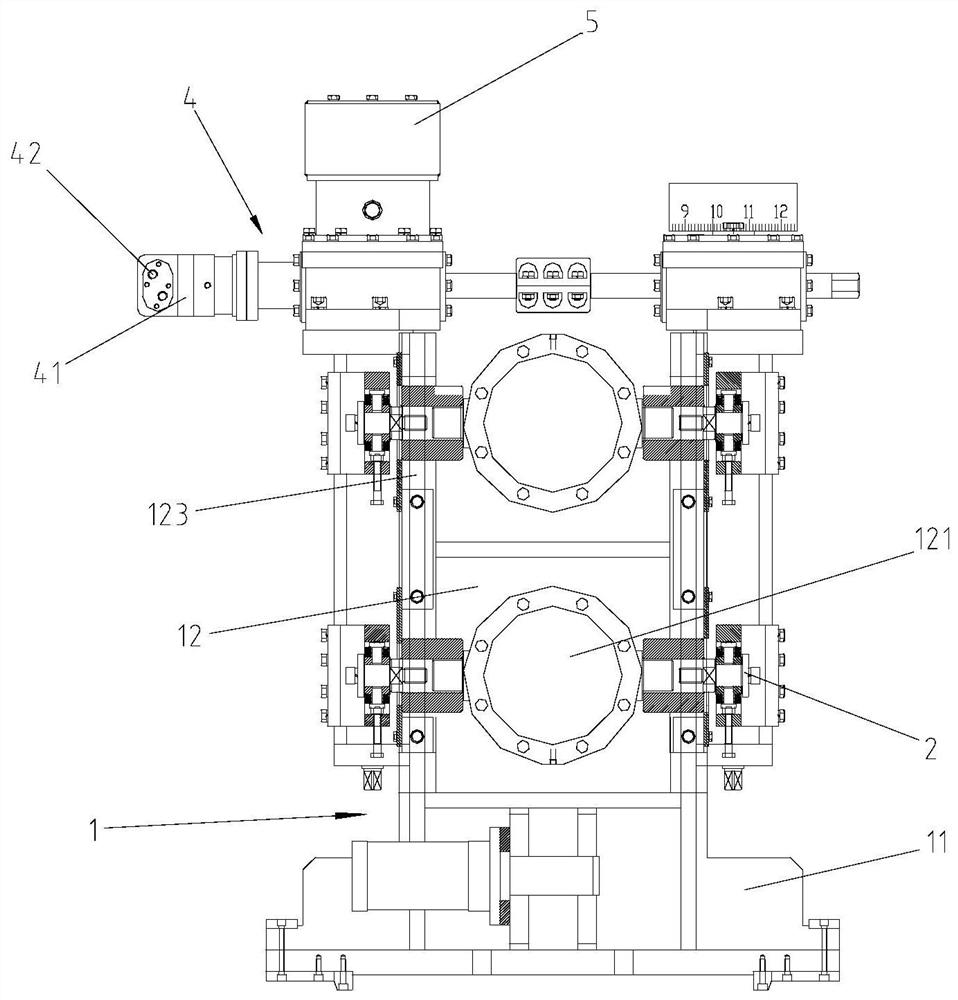

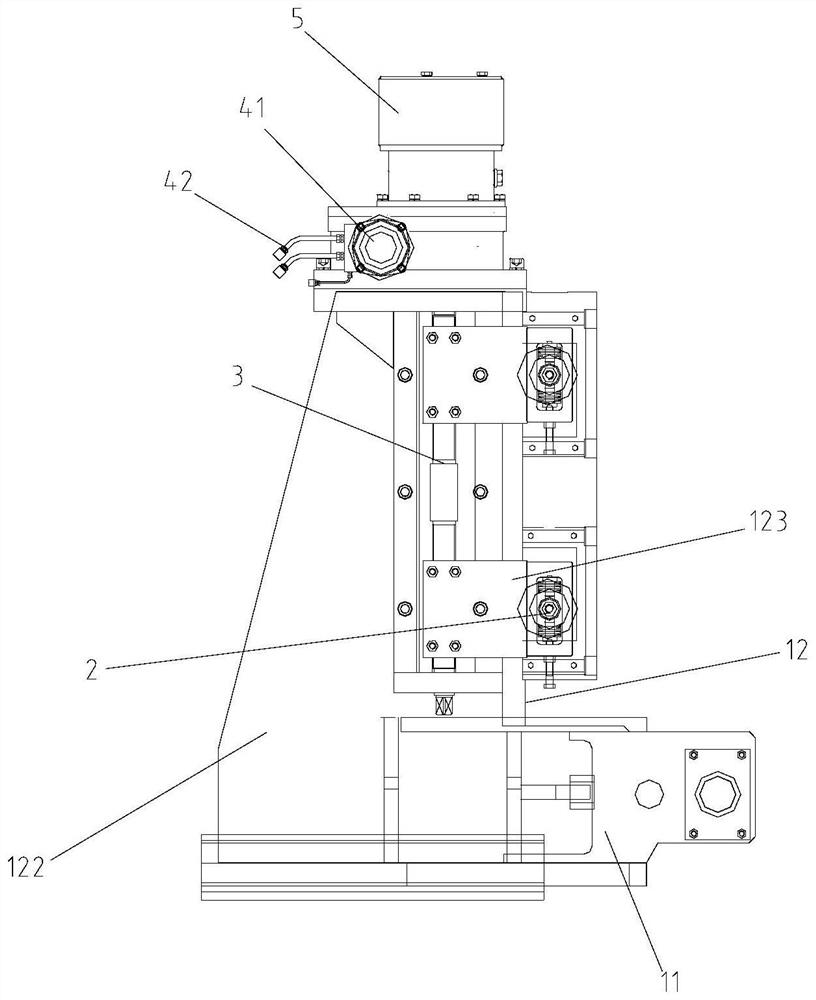

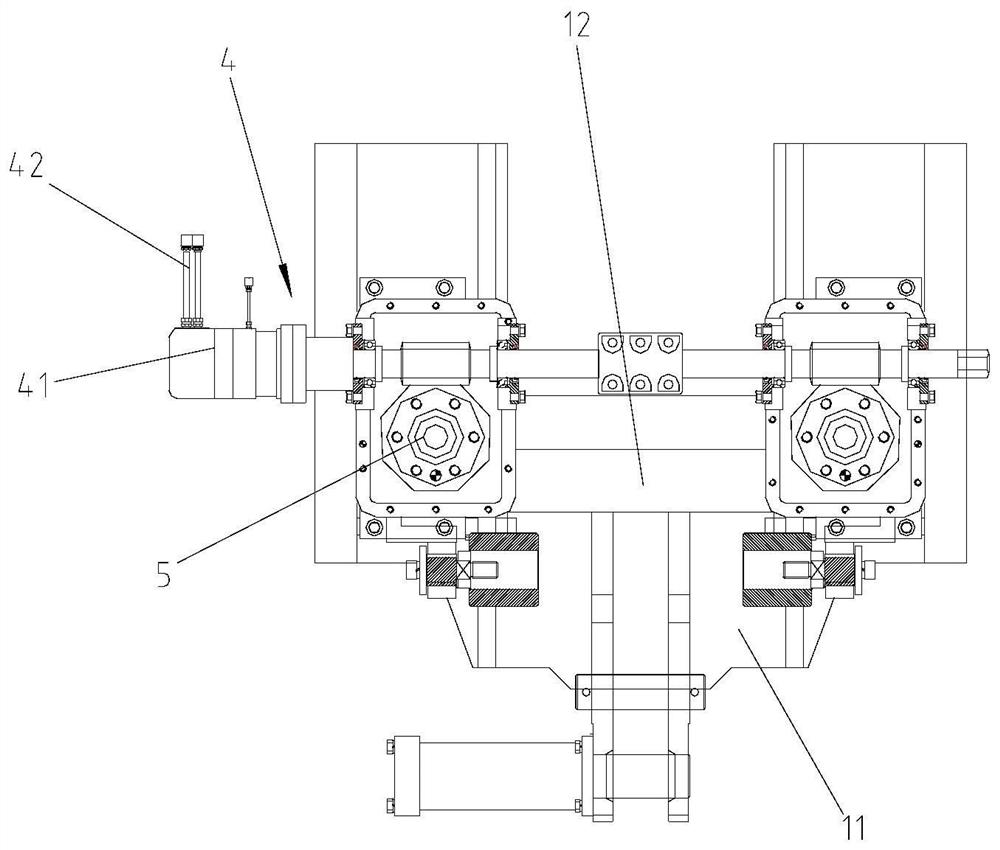

[0022] A new type of shaft bracket for short stress rolling mills, such as Figure 1-3 As shown, it includes a rolling mill bracket 1, elastic connectors 2 installed on both sides of the rolling mill bracket 1 and arranged symmetrically to each other, several connecting rods 3 installed inside the rolling mill bracket 1, installed on the The pressing device 4 on the top of the rolling mill bracket 1 and connected with the connecting rod 3 by bolts, and the code biaser 5 installed on the top of the rolling mill bracket 1 and located on the side of the pressing device 4 . The rolling mill bracket 1 includes a bracket base 11, a bracket body 12 formed by welding with the bracket base 11, through which the bracket body 12 is respectively fixed and installed with an elastic connector 2, an extension rod 3, a depressing device 4 and a code biaser 5. The middle part of the bracket body 12 is provided with a shaft mounting hole 121, specifically, the number of the shaft mounting hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com