Metallurgical replica material as well as preparation method and replica process thereof

A technology of process and raw materials, applied in the field of preparation method and replica technology, metallographic replica material, can solve problems such as difficulty in metallographic inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of metallographic replica material of the present invention, comprises the following steps successively:

[0040] The first step is to fully mix the powdered methyl violet with the curing agent, so that the methyl violet is fully dissolved in the curing agent, so as to ensure that the laminating film has a better contrast;

[0041] The second step is to mix the curing agent dissolved in the methyl violet in the first step and the epoxy resin in proportion, and stir it, and let it stand for at least 2 hours to obtain the metallographic replica material.

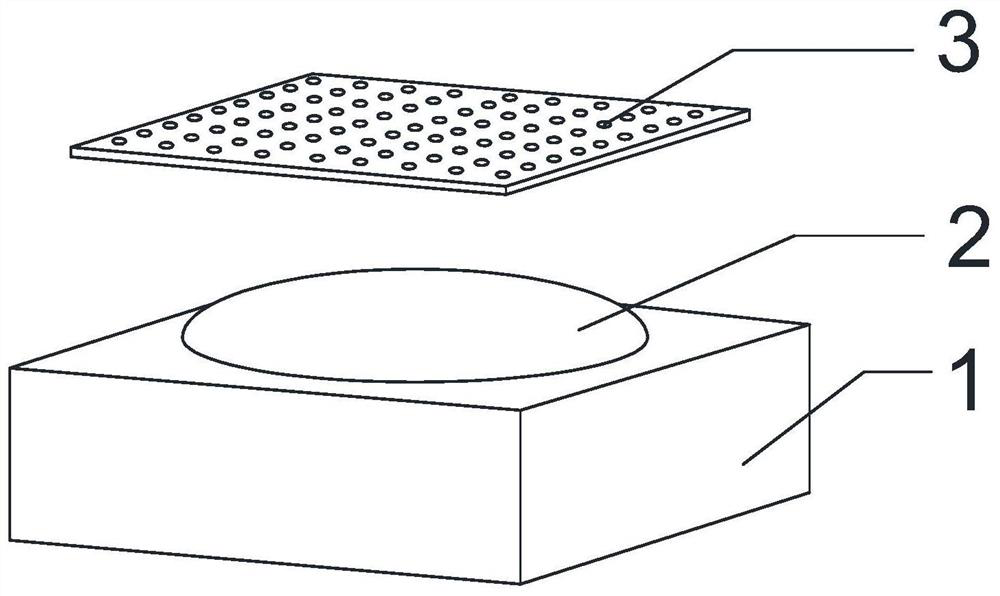

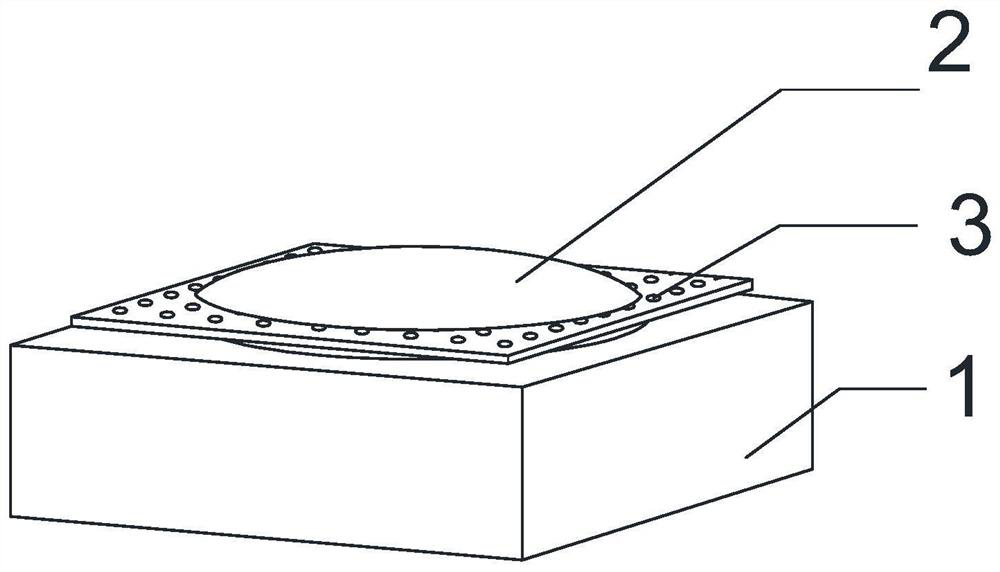

[0042] combine figure 1 with figure 2 As shown, during the replication process, an appropriate amount of metallographic replica material 2 can be poured directly on the inspection site of the inspected part 1, or an appropriate amount of replica material can be sucked up with a straw and dropped on the inspection site, and the composite material can be completely soaked in a liquid state. The c...

Embodiment 1

[0045] In this embodiment, an amine curing agent such as ethylenediamine is selected as the curing agent.

[0046] The first step: configure the metallographic replica material.

[0047] Metallographic replica materials can only be prepared and used immediately, but the configured replica materials need to be reserved for 2 hours of standing time. First, the powdered methyl violet and the curing agent ethylenediamine are fully mixed to allow the methyl violet to fully Dissolve in the curing agent ethylenediamine to ensure that the film has a good contrast, then mix the curing agent ethylenediamine and epoxy resin in proportion, and stir. The stirring direction is the same direction and cannot be replaced repeatedly Stirring direction, after fully mixing, let it stand for a period of time, usually 2 hours, to eliminate the air bubbles generated during mixing, so as to obtain the replica material. The prepared replica material should be a viscous purple transparent liquid. The ...

Embodiment 2

[0051] In this embodiment, a synthetic resin curing agent such as polyamide resin is selected as the curing agent.

[0052] The first step: configure the metallographic replica material.

[0053] Metallographic replica materials can only be prepared and used immediately, but the configured replica materials need to be reserved for 2 hours of standing time. First, the powdered methyl violet and the curing agent polyamide resin are fully mixed to allow the methyl violet to fully Dissolve in the curing agent polyamide resin to ensure that the lamination film has a good contrast, then mix the curing agent polyamide resin and epoxy resin in proportion, and stir, the stirring direction is the same direction, and cannot be replaced repeatedly Stirring direction, after fully mixing, let it stand for a period of time, usually 2 hours, to eliminate the air bubbles generated during mixing, so as to obtain the replica material. The prepared replica material should be a viscous purple tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com