Optical film and preparation method and application thereof

An optical film and film technology, applied in optics, optical components, nonlinear optics, etc., can solve problems such as accelerated optical film aging, and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

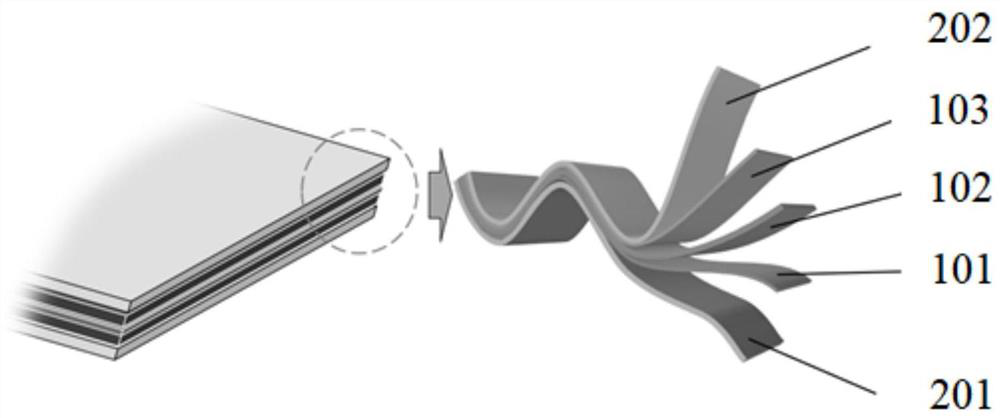

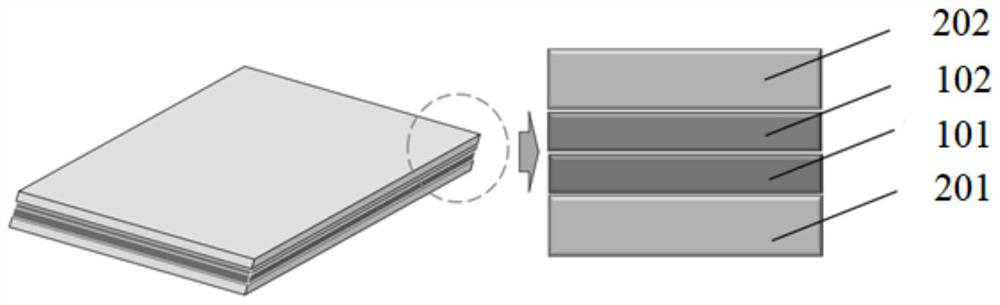

[0093] This embodiment provides an optical film such as figure 1 As shown in the figure, the optical film includes a first water and oxygen barrier film 201 (silicon nitride), a red light quantum dot light-emitting film 101 (thickness is 50 μm), and a green light quantum dot light-emitting film. 102 (thickness: 25 μm), blue quantum dot luminescent film 103 (thickness: 50 μm), and second water and oxygen barrier layer 202 (silicon nitride).

[0094] The preparation method of above-mentioned optical film comprises the steps:

[0095] (a) Preparation of quantum dot materials:

[0096] Dissolve InP, drop PMA, and then drop oleylamine to obtain a red light quantum dot material with a core-shell structure (luminescence peak wavelength is 630nm);

[0097] CsPbBr 3 Dissolved, SiO was added dropwise 2 , then drop oleylamine to obtain a green light quantum dot material with a core-shell structure (luminescence peak wavelength is 530nm);

[0098] Dissolve the CdSe system material, t...

Embodiment 2

[0109] This embodiment provides an optical film, which includes a first water and oxygen barrier film (aluminum oxide), a red light quantum dot luminescent film (thickness is 10 μm), and a green light quantum dot luminescent film that are sequentially stacked. (thickness is 5 μm), blue light quantum dot luminescent film (thickness is 10 μm), and the second water and oxygen barrier film (aluminum oxide).

[0110] The preparation method of above-mentioned optical film comprises the steps:

[0111] (a) Preparation of quantum dot materials:

[0112] Dissolve CdSe, drop ZrO 2 , then drop oleic acid to obtain a red light quantum dot material with a core-shell structure (luminescence peak wavelength is 600nm);

[0113] CsPbBr 3 Dissolve, add PVDF dropwise, and drop oleic acid again to obtain a green light quantum dot material with a core-shell structure (luminescence peak wavelength is 510nm);

[0114] Dissolve InP, then add TiO 2 , ZrO 2 and ZnO, and then drop oleic acid to ob...

Embodiment 3

[0125] This embodiment provides an optical film, which includes a first water and oxygen barrier film (silicon carbide), a red light quantum dot light-emitting film (thickness is 80 μm), and a green light quantum dot light-emitting film that are sequentially stacked. (thickness is 50 μm), blue light quantum dot luminescent film (thickness is 80 μm), and the second water and oxygen barrier film (silicon carbide).

[0126] The preparation method of above-mentioned optical film comprises the steps:

[0127] (a) Preparation of quantum dot materials:

[0128] CsPbBr 3 Dissolve, drop TiO 2 , and then drop long-chain phosphonic acid to obtain a red light quantum dot material with a core-shell structure (luminescence peak wavelength is 660nm);

[0129] Dissolve InP, drop TiO 2 , and then drop long-chain phosphonic acid to obtain a green light quantum dot material with a core-shell structure (luminescence peak wavelength is 550nm);

[0130] Dissolve CdSe, then add TiO 2 , and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com