Folding method of wrapping substrate for lithium battery

A folding method and technology for lithium batteries, which are applied in lithium storage batteries, secondary batteries, battery assembly machines, etc., can solve the problems of increasing production costs, difficulty in folding, and low efficiency, and achieve high setting efficiency, improve efficiency, and reduce difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

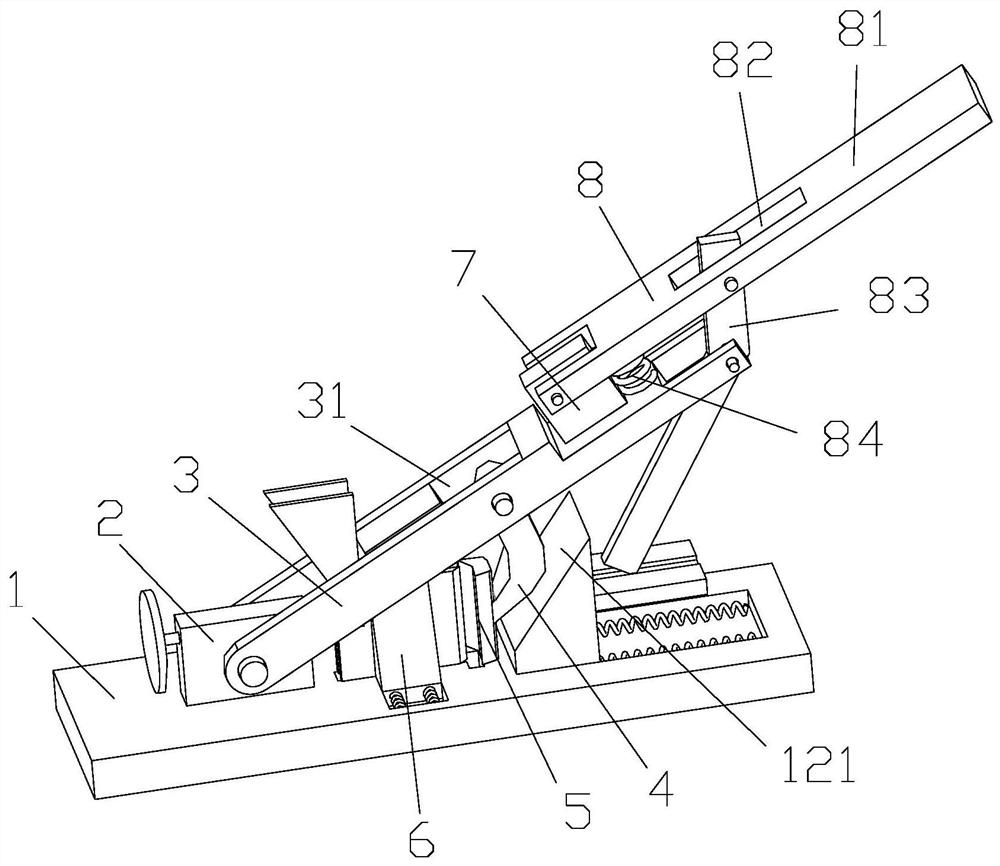

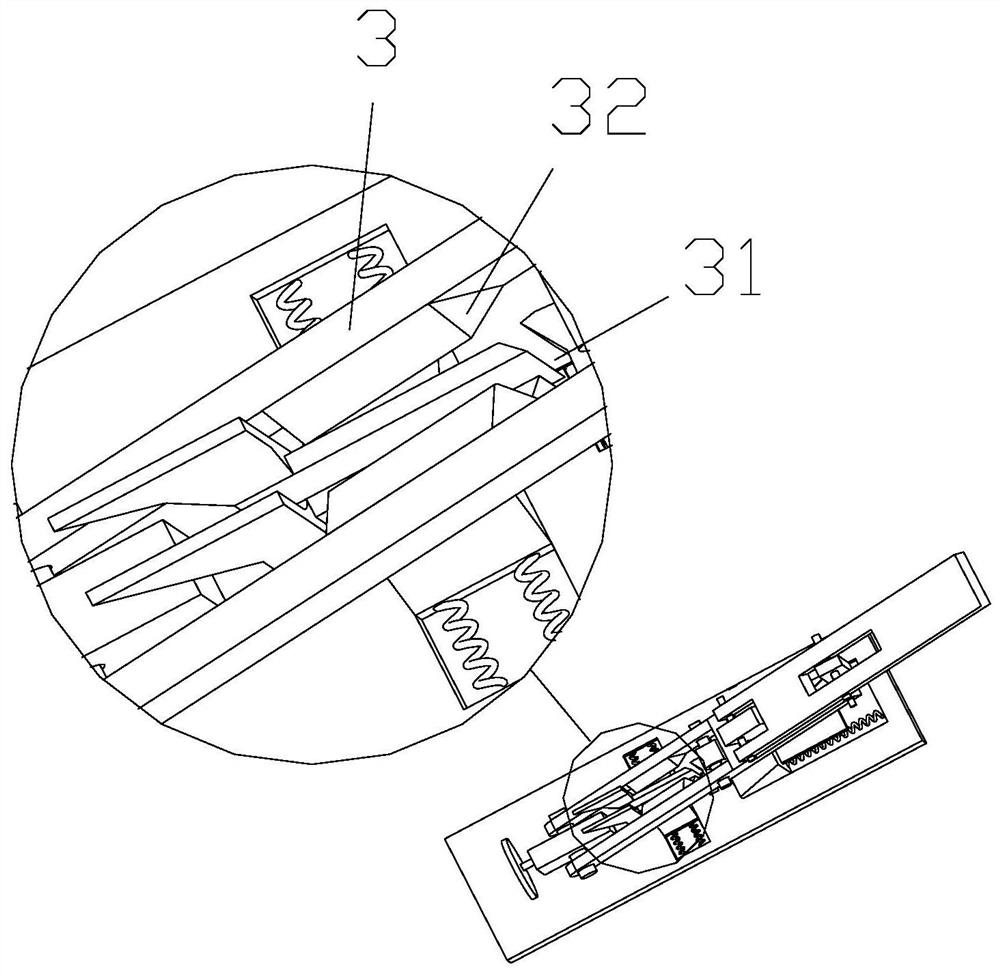

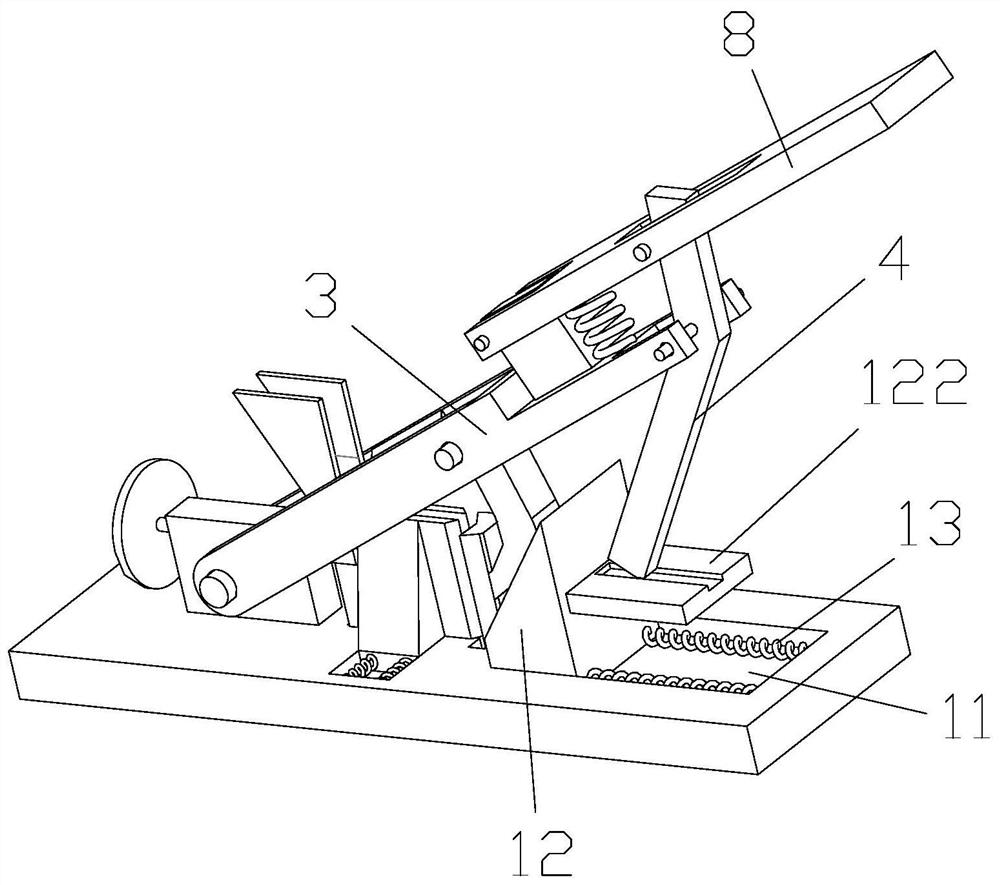

[0032] Attached below Figure 1-9 The present invention is further described with embodiment:

[0033] A folding mechanism for wrapping substrates for lithium batteries, comprising a support plate 1 and a first support 2, the first support 2 is arranged on the upper surface of the support plate 1, and the first support 2 is hinged with a first Pressing rod 3, and the first pressing rod 3 extends away from the direction of the first support 2; the upper end surface of the first pressing rod 3 is vertically downwardly penetrated with a through groove 31, and each of the two side walls of the through groove 31 is provided with There is an oblique pressing block 32, the upper part of the oblique pressing block 32 is provided with a first inclined surface 321, and the lower part is provided with a second inclined surface 322; the end of the through groove 31 different from the first support 2 is hinged with a first push rod 4 , the lower end of the first push rod 4 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com