A single-atom photocatalyst for hydrogen production and its preparation method and application

A catalyst and photocatalytic technology, applied in the field of photocatalytic materials, can solve the problems of cost limitation and high scarcity, and achieve the effects of improved efficiency, good activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

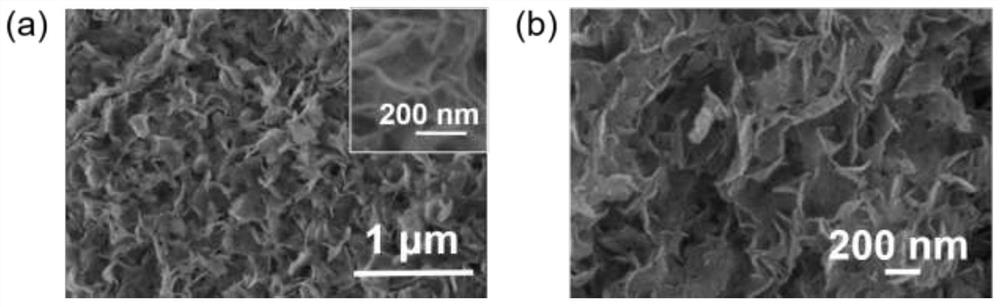

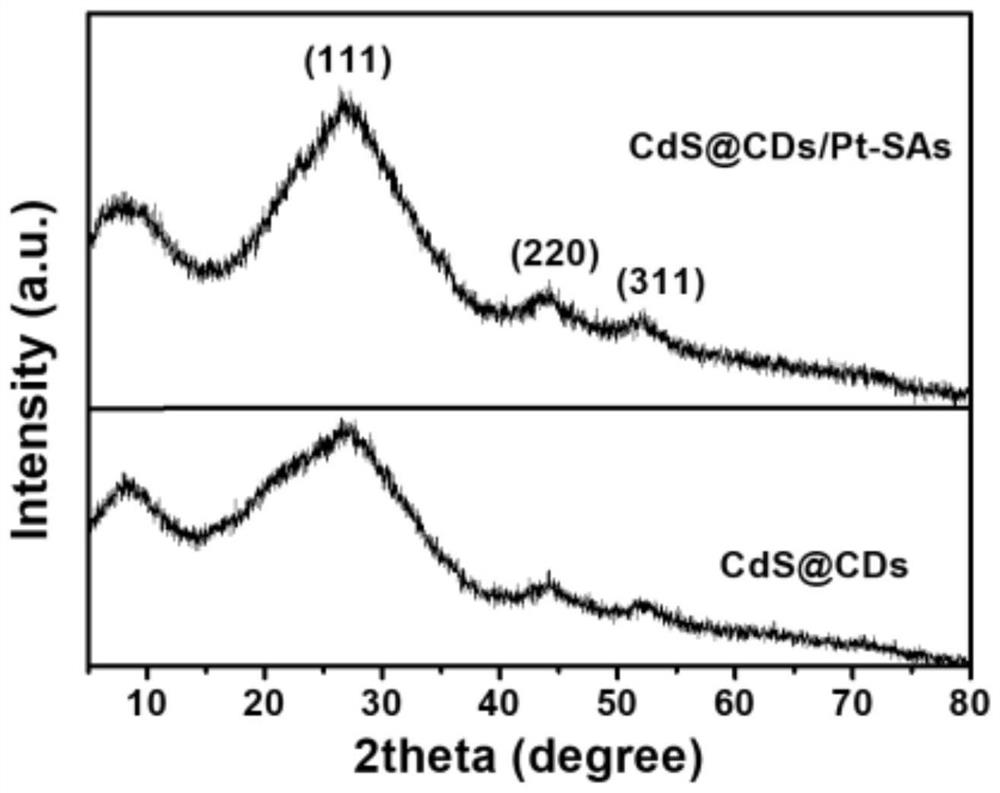

[0030] (2) Preparation of CdS@CDs nanosheets: add 0.01-0.02g Cd(OH) to 60-80mL deionized water 2 @CDs, add 150-200mL of Na Na after freezing for 1-1.5h under magnetic stirring 2 S (3-6mmol / L) solution, react it at room temperature for 10-30min and then add an equal amount of Na again 2 S solution to obtain porous CdS@CDs nanosheets, the product was washed and vacuum dried;

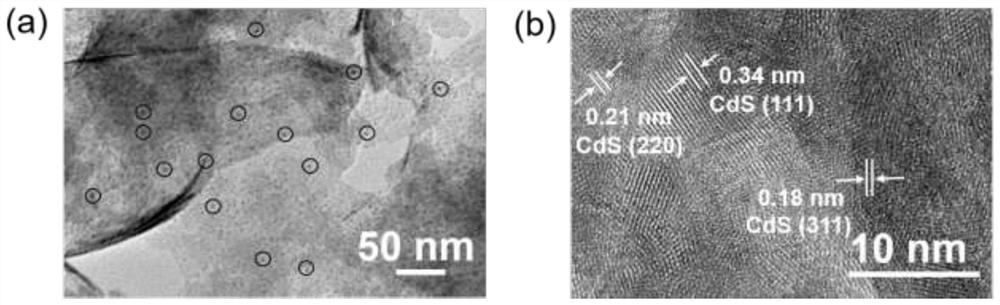

[0031] (3) Preparation of CdS@CDs / Pt-SAs by dipping method: add 15-20 mg of CdS@CDs nanosheets to a beaker containing 8 mL of distilled water, and slowly add another 20 mL of H with a concentration of 0.06 mg / mL dropwise with a peristaltic pump. 2 PtCl 6 The solution was reacted under magnetic stirring for 4 h to obtain the CdS@CDs / Pt-SAs ultra-flake-like structure composite catalyst, and the product was washed and vacuum-dried.

[0032] The present invention develops a new preparation technology of Pt single atoms in CdS@CDs, the photocatalytic hydrogen production efficiency is greatly improved, and the ...

Embodiment 1

[0037] CdS@CDs precursor Cd(OH) 2 Preparation of @CDs:

[0038] Cadmium acetate Cd(CH 3 COO) 2 ·2H 2 O and n-butylamine were dissolved in an appropriate amount of ethylene glycol and carbon dots mixture, stirred for half an hour, and then transferred to a 100 mL reaction kettle for 5 hours at 120 °C to obtain CdS precursor Cd(OH) 2 @CDs nanosheets, the product was washed and vacuum dried.

Embodiment 2

[0040] Preparation of CdS@CDs nanosheets:

[0041] Add 0.01-0.02g Cd(OH) to 60-80mL deionized water 2 @CDs, add 150-200 mL of Na Na after freezing for 1-1.5 h under magnetic stirring 2 S (3-6mmol / L) solution, react it at room temperature for 10-30min and then add an equal amount of Na again 2 S solution, porous CdS@CDs nanosheets were obtained, and the product was washed and vacuum-dried; the obtained brown CdS@CDs could be directly used as a photohydrogen production catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com