A method for preparing zinc oxide/zinc sulfide nano-heterojunction photocatalyst

A photocatalyst and heterojunction technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., to achieve the effects of easy reuse, good stability, and high photocatalytic hydrogen production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

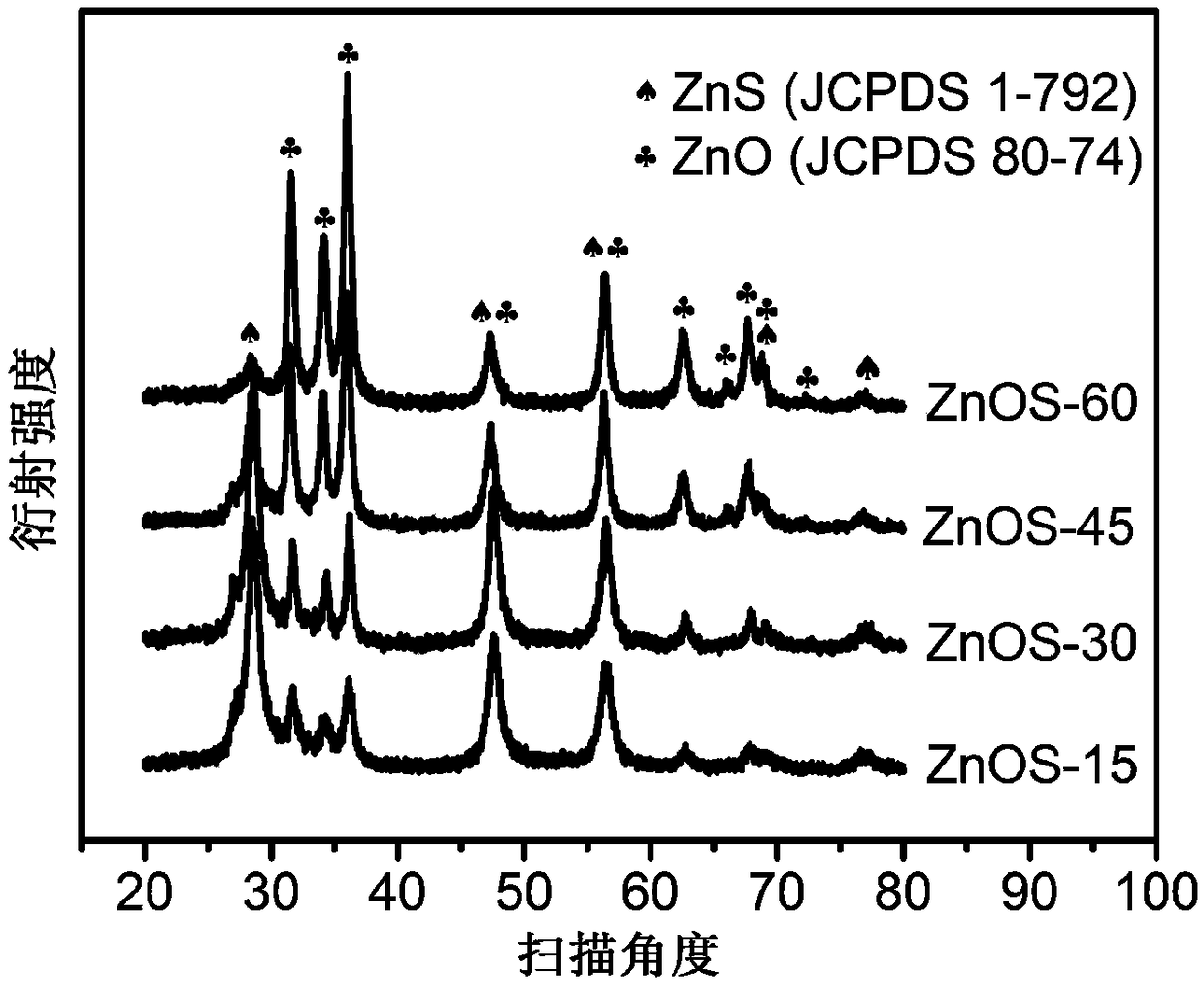

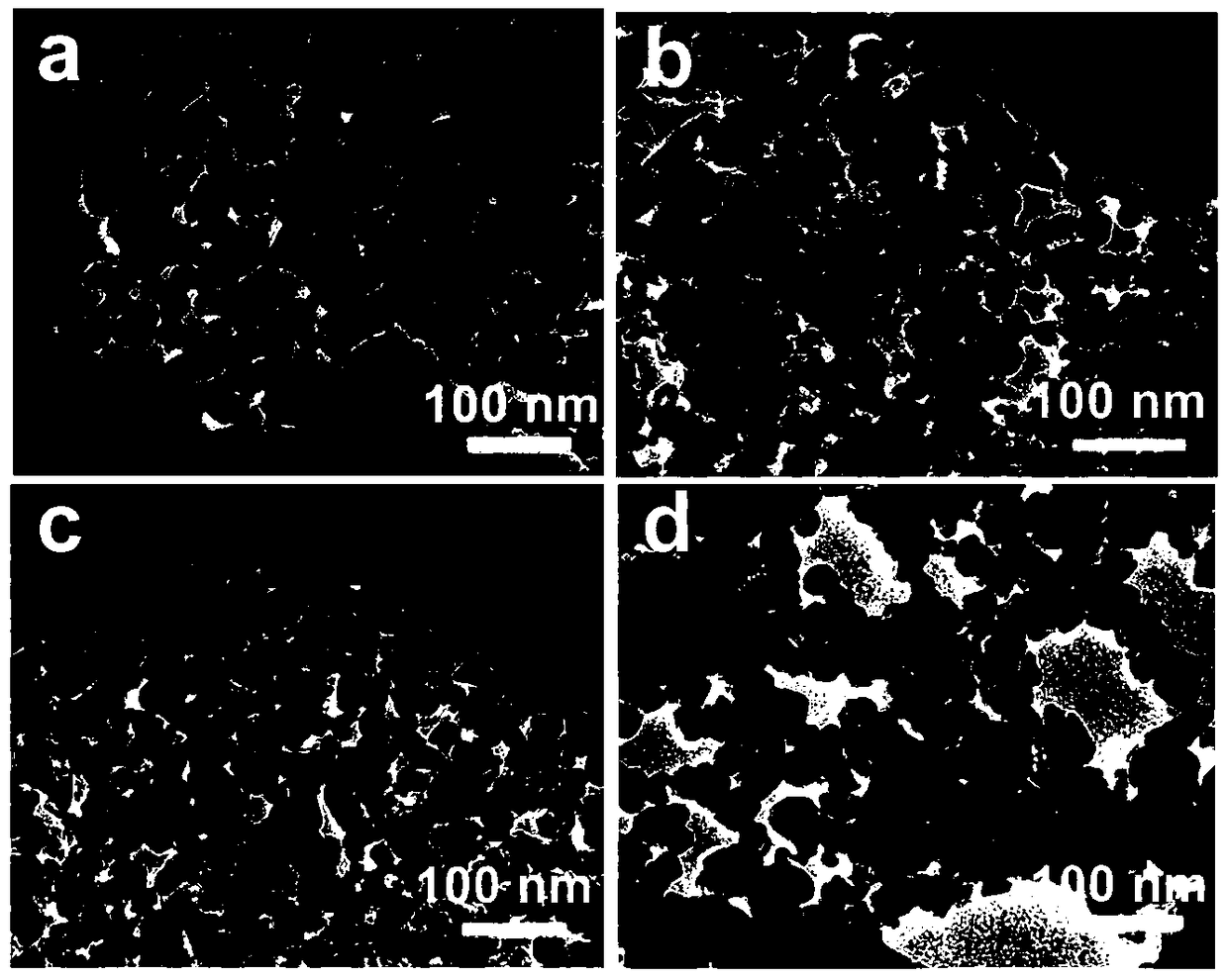

[0024] A method for preparing ZnO / ZnS heterojunction nanoparticle photocatalyst, the steps are as follows:

[0025] 1) Dissolve 2.98 g (10 mmol) of zinc nitrate hexahydrate in 25 ml of N-N-dimethylformamide to form solution 1, and dissolve 0.33 g (2 mmol) of terephthalic acid in 65 ml of N-N-dimethylformamide. In methylformamide, solution 2 was formed, then solution 1 was added to solution 2, mixed evenly, placed at 100 ° C for reflux reaction for 12 hours, naturally cooled and filtered, and the obtained solids were respectively treated with N-N-dimethylformamide. The amide and methanol were washed three times, and finally dried under vacuum at 70 °C for 12 h to obtain a white powdery solid metal-organic framework complex MOF-5.

[0026] 2) 80 mg of the above-mentioned metal-organic framework complex MOF-5 and 160 mg of thioacetamide were added to 16 ml of ethanol, placed in an oven at 120° C. for 4 hours, centrifuged after natural cooling, and the obtained solid was treated w...

Embodiment 2

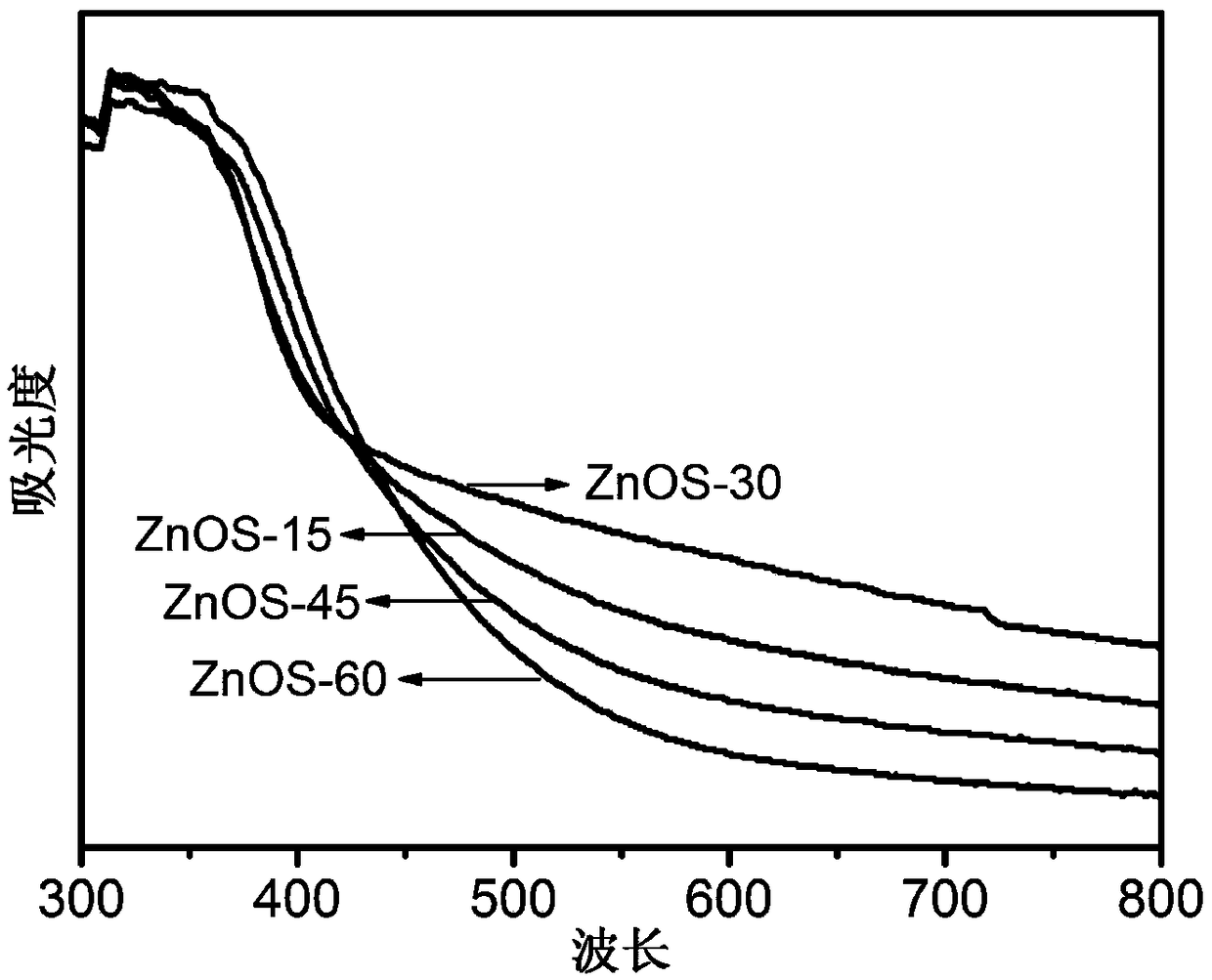

[0030] The steps are the same as those in Example 1, except that the calcination at 550° C. for 15 minutes in an air atmosphere in Example 1 is changed to calcination for 30 minutes. The resulting ZnO / ZnS heterojunction is labeled as ZnOS-30. The photocatalytic hydrogen production efficiency of this material was 415.3 μmol / hour (1 g of catalyst).

Embodiment 3

[0032] The steps are the same as in Example 1, except that the calcination at 550 °C for 15 minutes in an air atmosphere in Example 1 is changed to calcination for 45 minutes. The resulting ZnO / ZnS heterojunction is labeled as ZnOS-45. The photocatalytic hydrogen production efficiency of this material was 53.6 μmol / hour (1 g of catalyst).

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com