Discharge system for electrostatic voltage adjustment of high-voltage electrostatic equipment

A technology of high-voltage static electricity and static voltage, applied in the field of high-voltage static electricity, can solve problems such as difficult control, impact on life, and distance reduction, and achieve the effects of simple production procedures, prevention of creepage, and less failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

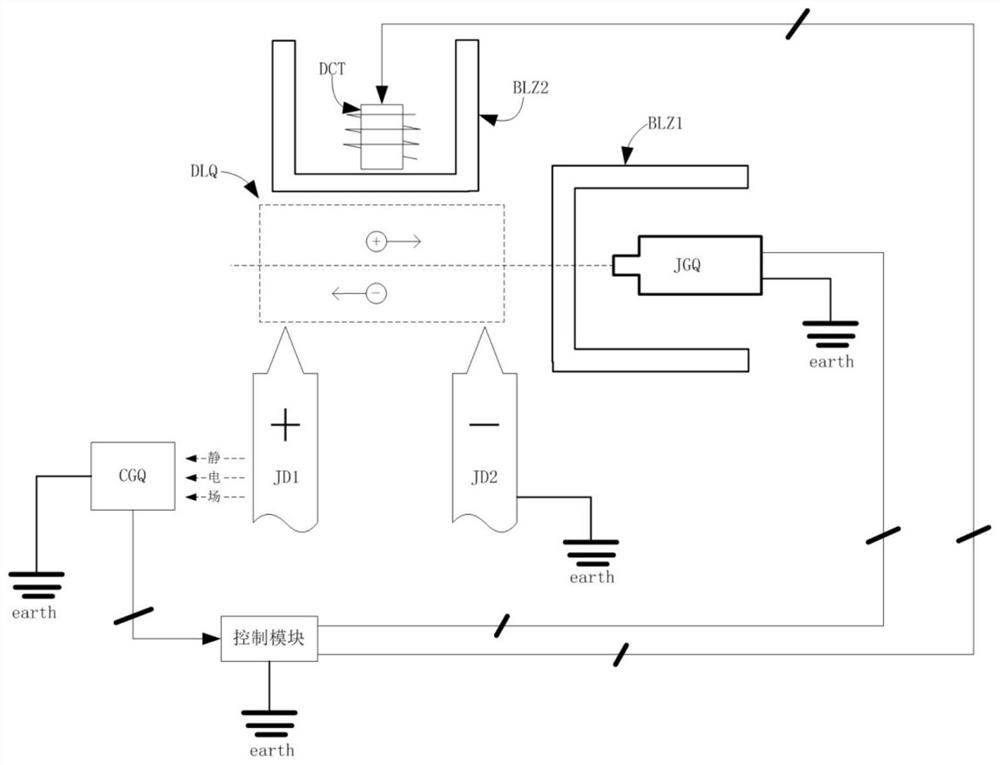

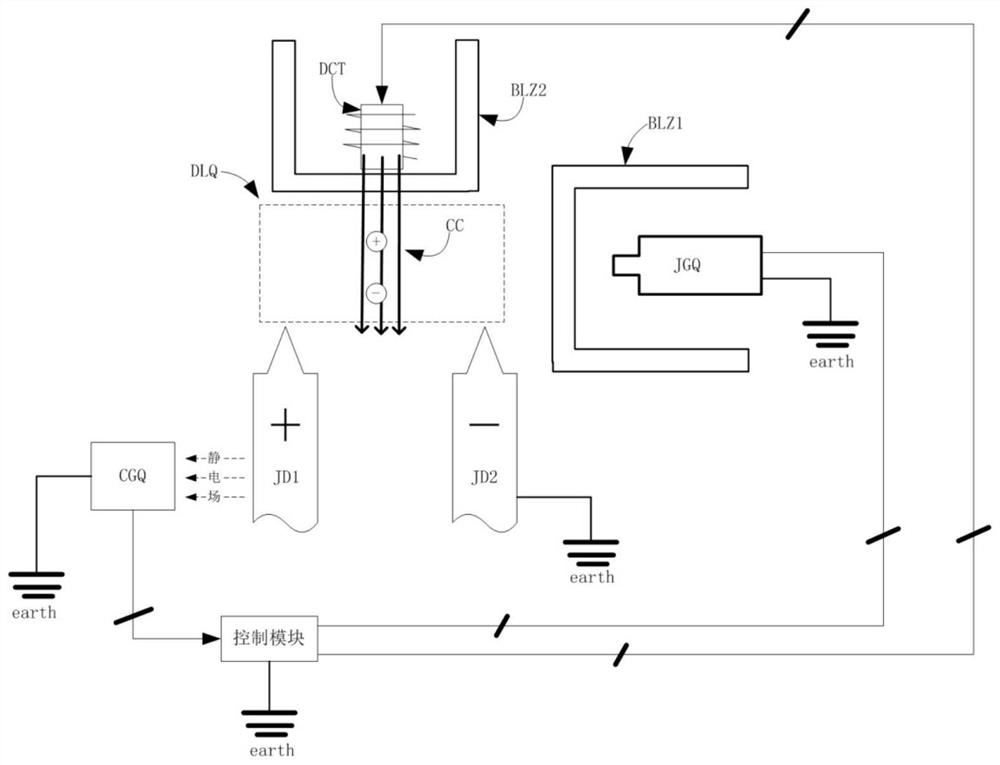

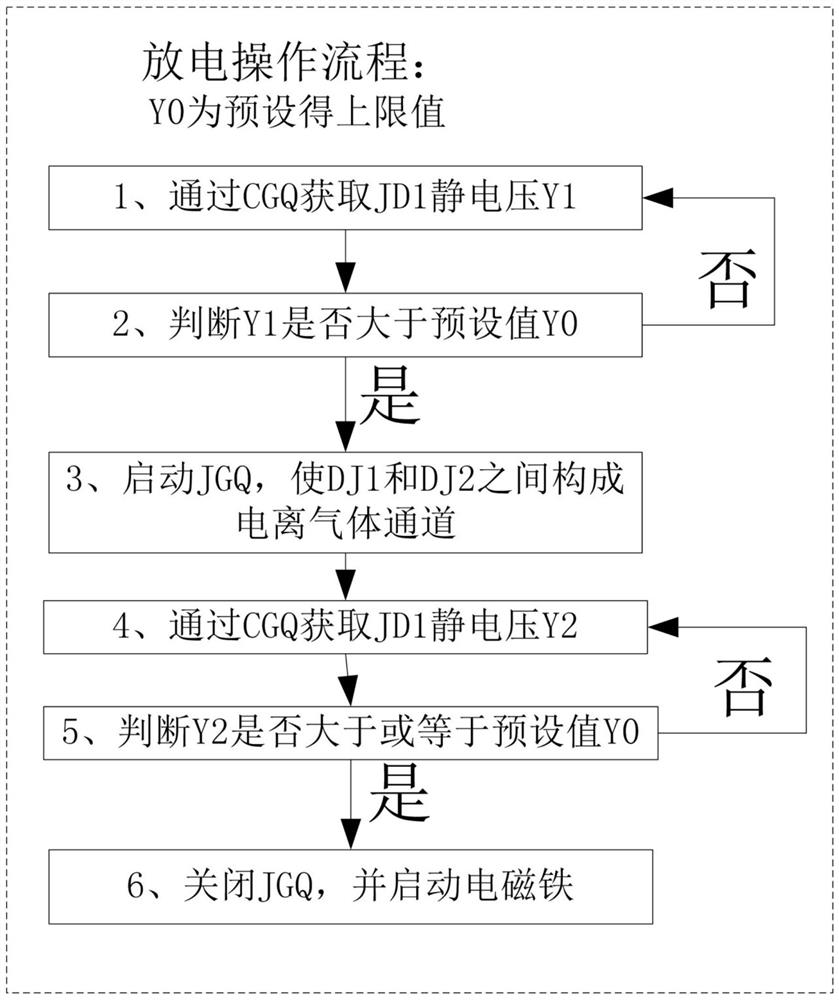

[0041] Embodiment 1. A discharge system for adjusting the electrostatic voltage of high-voltage electrostatic equipment, which is characterized in that it includes a laser (JGQ), a control module, an electrostatic field sensor (CGQ), an electromagnet (DCT), and a first electrode (JD1) , the second electrode (JD2);

[0042] The laser (JGQ), the control module, and the electrostatic field sensor (CGQ) share the same ground, and the site of the entire system is the ground;

[0043] The second electrode (JD2) is a negative pole, and there is an electrical connection between the second electrode (JD2) and the ground;

[0044] The first electrode (JD1) is connected to the positive output of the high-voltage electrostatic equipment;

[0045] The second electrode (JD2) is connected to the output negative pole of the high-voltage electrostatic equipment;

[0046] The electrostatic field sensor (CGQ) can detect the electrostatic field strength on the surface of the first electrode (JD...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com