Kitchen garbage self-heating drying and continuous fertilizer preparation device and method

A kitchen waste drying technology, applied to chemical instruments and methods, separation methods, organic fertilizers, etc., to reduce the cost of collection, transportation and subsequent treatment and disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

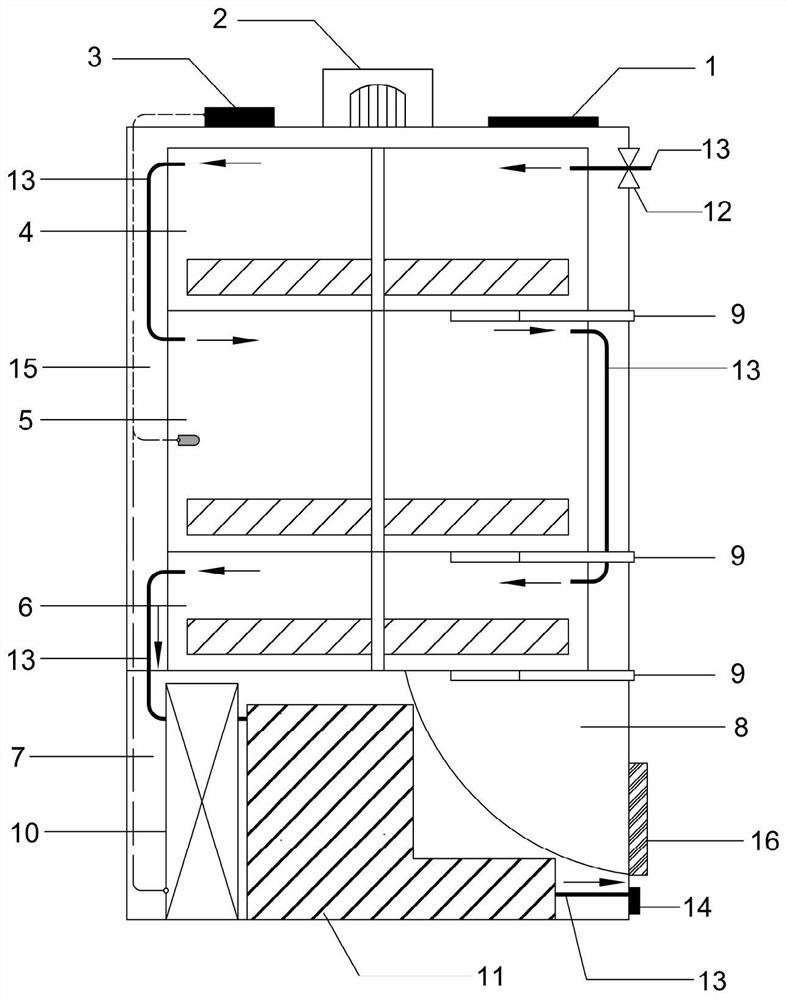

[0026] Such as figure 1 As shown, in the embodiment of the present invention, a kitchen waste self-heating drying and continuous fertilizer making device includes a tank body, the top of the tank body is provided with a feeding port 1, and the bottom is provided with a material outlet port 16 and an air outlet port 14. The tank is divided into area 1 and area 2, with a total volume of 100L.

[0027] In other optional embodiments of the present invention, the tank body may also adopt a split structure, that is, a tank body is used in the first area and the second area respectively. Feeding port 1 is in the tank body of area 1, and material outlet 16 and gas outlet 14 are in the tank body of area 2.

[0028] Area 1 is further divided into pre-fermentation area 4, main fermentation area 5 and decomposing area 6 from top to bottom. Feeding port 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com