Alkyl-polyethoxy-sodium naphthalenesulfonate foam oil displacement agent and its preparation method

A technology of foam flooding and polyethoxy, which is applied in chemical instruments and methods, reagents, products, etc., can solve the problems of high-temperature foam being difficult to stabilize, restricting the practical application of foam flooding, and short half-life of foam, so as to improve oil resistance, The effect of improving stability and increasing the expansion ratio

Active Publication Date: 2022-06-03

PETROCHINA CO LTD

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

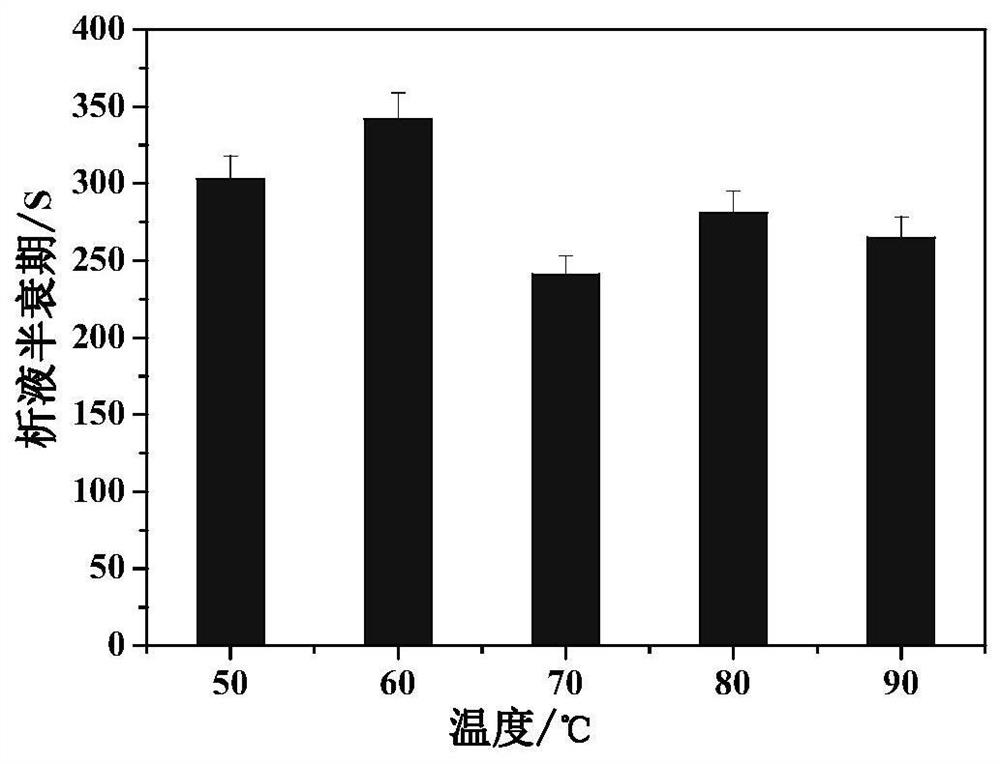

[0006] The embodiment of the present application provides an alkyl-polyethoxy-naphthalene sodium sulfonate foam oil displacement agent and its preparation method, which can solve the problem that high-temperature foam is difficult to stabilize in the related art, resulting in a short half-life of the foam, which seriously restricts foam flooding. Practical Application Issues in High Temperature Reservoirs

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

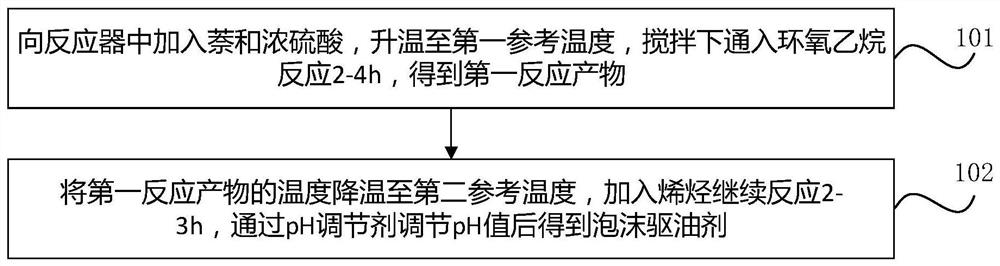

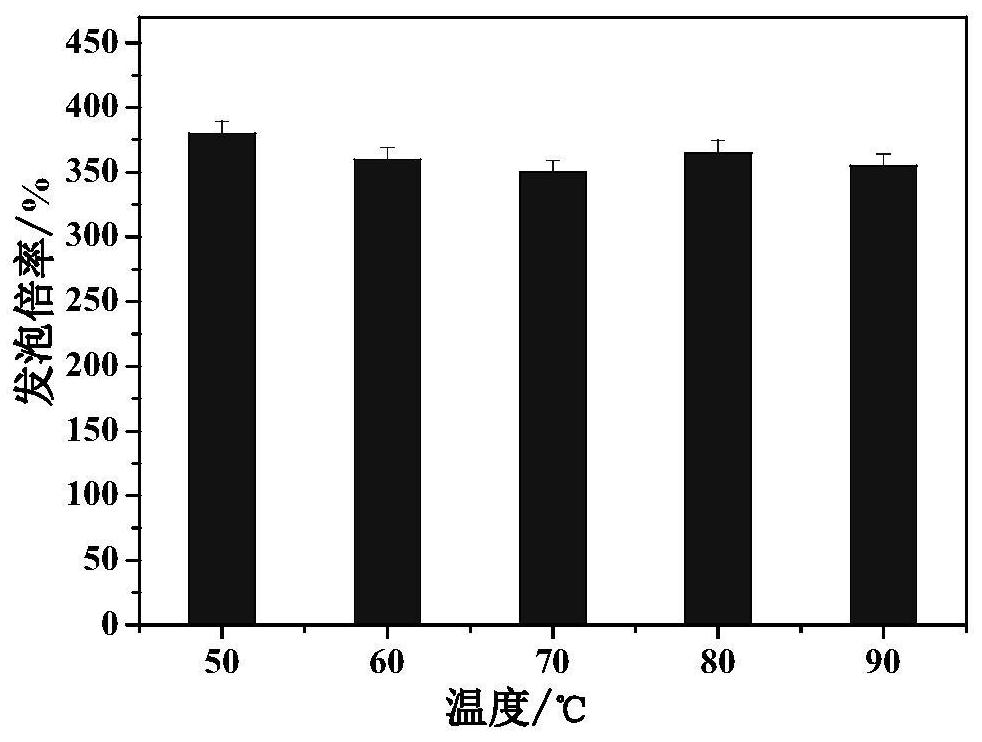

The application discloses an alkyl-polyethoxy-naphthalenesulfonate sodium foam agent flooding and a preparation method thereof, belonging to the technical field of tertiary oil recovery. The method comprises: adding naphthalene and concentrated sulfuric acid into a reactor, heating up to a first reference temperature, feeding ethylene oxide under stirring, and reacting for 2-4h to obtain a first reaction product; The temperature is lowered to the second reference temperature, olefins are added to continue the reaction for 2-3 hours, and the pH value is adjusted by a pH regulator to obtain the alkyl-polyethoxy-naphthalenesulfonate sodium foaming agent. The application improves the stability of the foam oil displacement agent, has excellent foam stabilizing performance, and improves the oil resistance of the foam oil displacement agent. Since the olefin group is a lipophilic group, the oil-water balance of the foam oil displacement agent is balanced, and the foam oil displacement agent is improved. The foaming ratio of the oil displacing agent.

Description

Alkyl-polyethoxy-sodium naphthalene sulfonate foam oil displacing agent and preparation method thereof technical field The application relates to tertiary oil recovery technical field, particularly a kind of alkyl-polyethoxy-sodium naphthalene sulfonate foam flooding agent and its preparation method. Background technique There is a large amount of low-permeability, high water-cut heavy oil reservoirs in my country at present, and gas flooding is to improve recovery factor for above-mentioned oil fields However, the above-mentioned oil reservoirs have a large number of fractures due to complex formation structures and fracturing operations. Therefore, by Excessive gas flooding will cause problems such as gas channeling in oil wells, resulting in a decrease in the oil displacement effect. Foam flooding as an important part in tertiary oil recovery The oil displacement method has been widely used in the fields of profile control, water plugging and oil displacement in...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08G65/26C08G65/329C09K8/584

CPCC08G65/26C08G65/329C09K8/584Y02P20/141

Inventor 王洪涛张玉珍何萌曾庆桥冯丽娟章峻

Owner PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com