Assembly type special-shaped column-beam connecting joint capable of being repaired after earthquake

A technology for connecting nodes and special-shaped columns, which is applied in the field of prefabricated special-shaped column-beam connection nodes, and can solve problems such as low assembly rate, stress concentration, and restrictions on the development of prefabricated high-rise steel structure systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

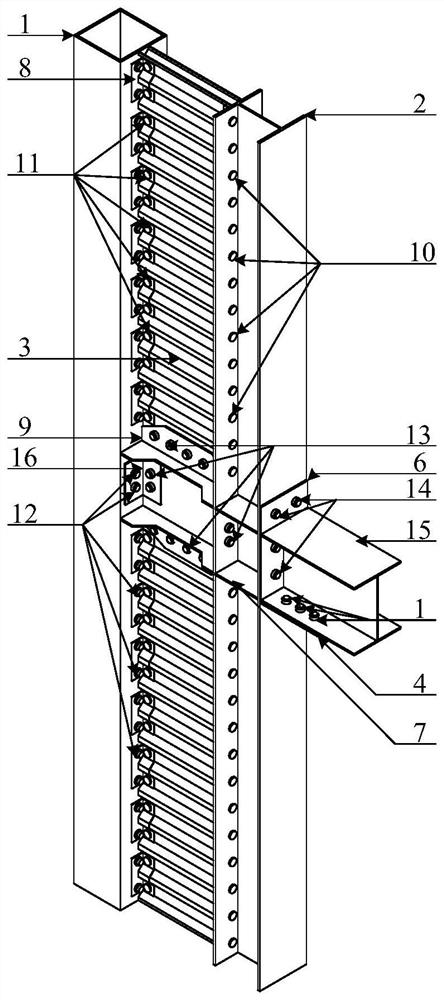

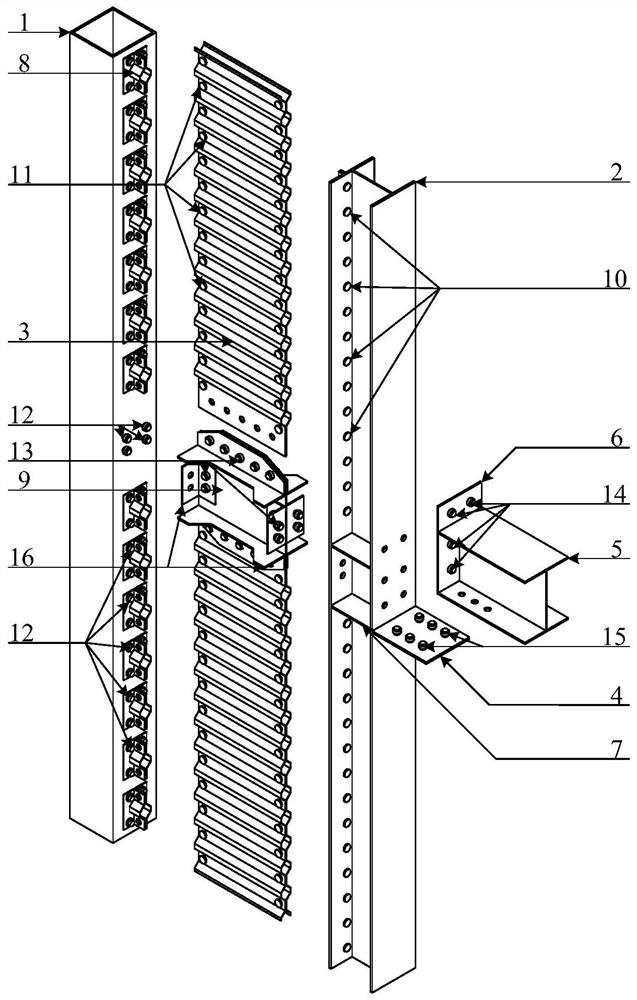

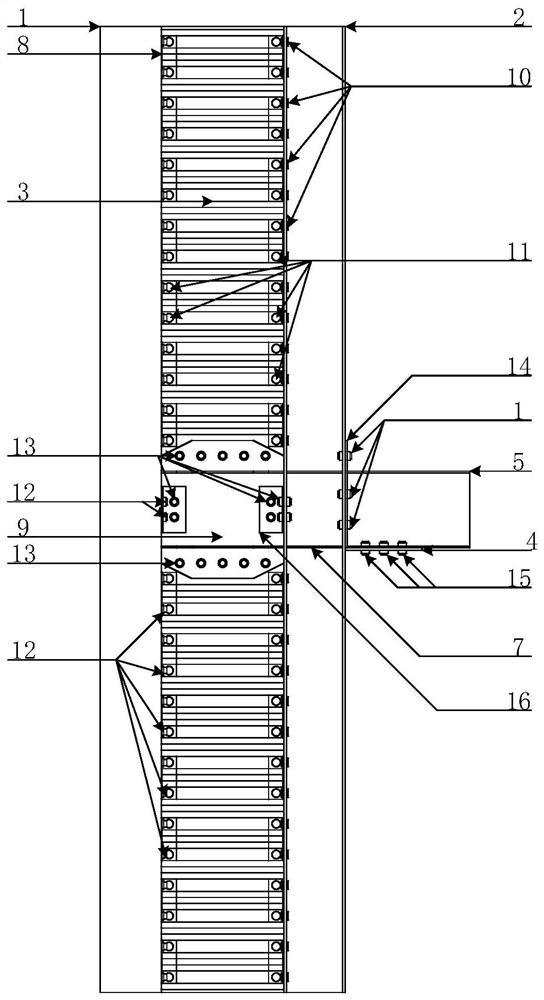

[0024] Attached below Figure 1-9 , detailing the implementation of this patent.

[0025] like Figure 1-9 As shown, a post-earthquake repairable assembled special-shaped column-beam connection node includes the following components:

[0026] 1——square steel column

[0027] 2——Steel column

[0028] 3——corrugated board

[0029] 4——Pallet

[0030] 5——I-beam

[0031] 6——End plate

[0032] 7——Stiffening plate

[0033] 8——corrugated angle steel

[0034] 9——Weaken the coupling beam section

[0035] 10——The first high-strength bolt group

[0036] 11——The second high-strength bolt group

[0037] 12——The third unilateral bolt group

[0038] 13——The fourth high-strength bolt group

[0039] 14——The fifth high-strength bolt group

[0040] 15——The sixth high-strength bolt group

[0041] 16——Angle steel connector

[0042] 17 - Lianliang

[0043] 18——Flange outer end plate

[0044] The specific connection mode of the beam-column node connection device of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com