Building aluminum formwork capable of being adjusted at different angles

A technology of angle adjustment and aluminum formwork, which is applied in the direction of architecture, building structure, formwork/formwork components, etc., can solve the problems affecting the quality of concrete pouring, the overall instability of the support system, and the instability of formwork reinforcement, etc., to achieve overall flatness Good, improve the quality of pouring, the effect of tight joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

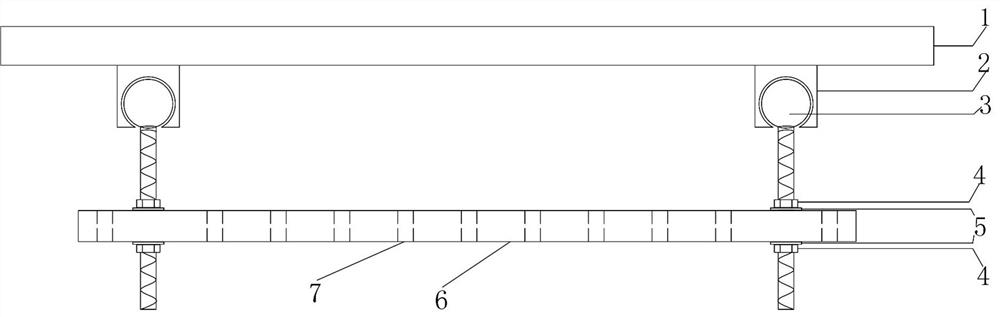

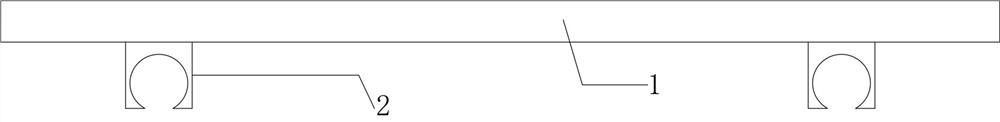

[0019] Such as Figure 1 to Figure 6 As shown, the present invention relates to a building aluminum formwork that can be adjusted at different angles. The main structure of the formwork system includes an aluminum formwork surface 1 and a formwork support. The top of the formwork support is hinged to the aluminum formwork surface 1. A height Regulating mechanism.

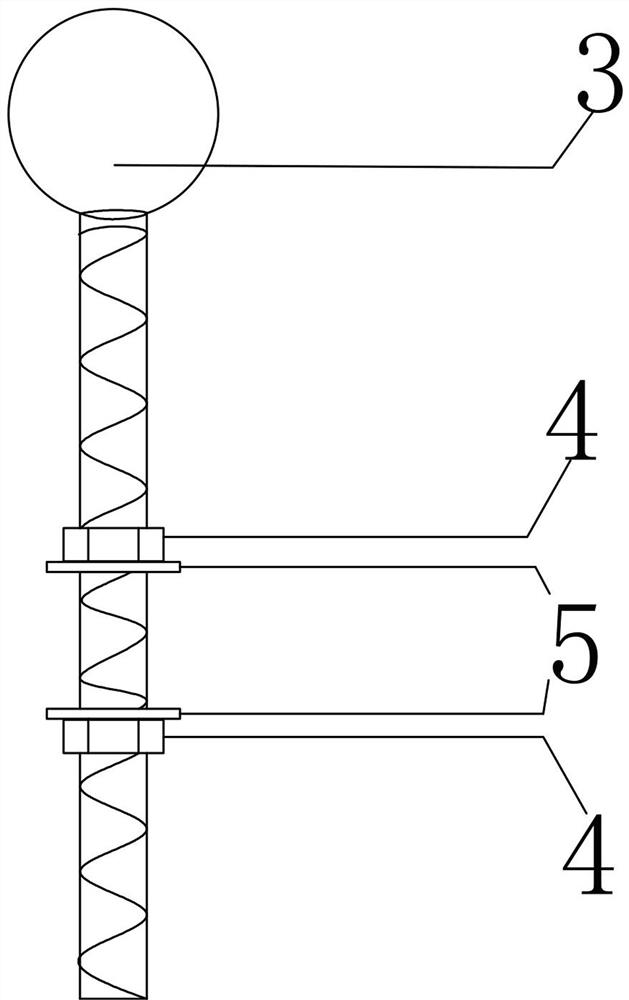

[0020] Wherein, the formwork support includes four screw rods 3 with round heads, movable hinge supports 2, two parallel and symmetrically distributed formwork support square steel pipes 6 and short square steel pipes 8 connected therebetween. The movable hinge supports 2 are respectively fixed on the four corners of the back of the aluminum formwork surface 1 by welding, and four screw rods 3 with round heads are respectively embedded and hinged in the corresponding movable hinge supports 2 to fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com