Multi-airplane-type airplane weight gravity center automatic measuring device

A technology for measuring devices and aircraft, which is applied in the testing of measuring devices, machine/structural components, static/dynamic balance testing, etc. It can solve the problem that data accuracy, efficiency, and versatility cannot meet development needs, and the skills of testers are relatively high. High, can not eliminate problems such as lateral force, to achieve the effect of easy operation, not easy to tip over, and easy to adjust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

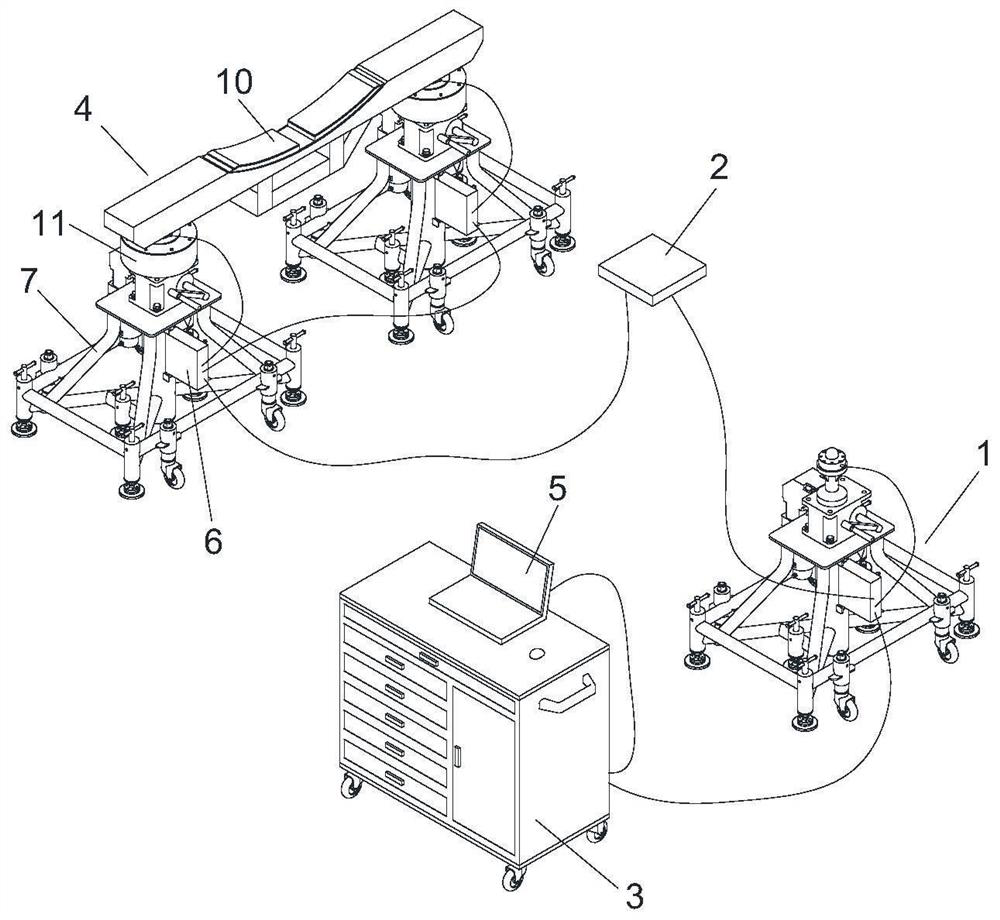

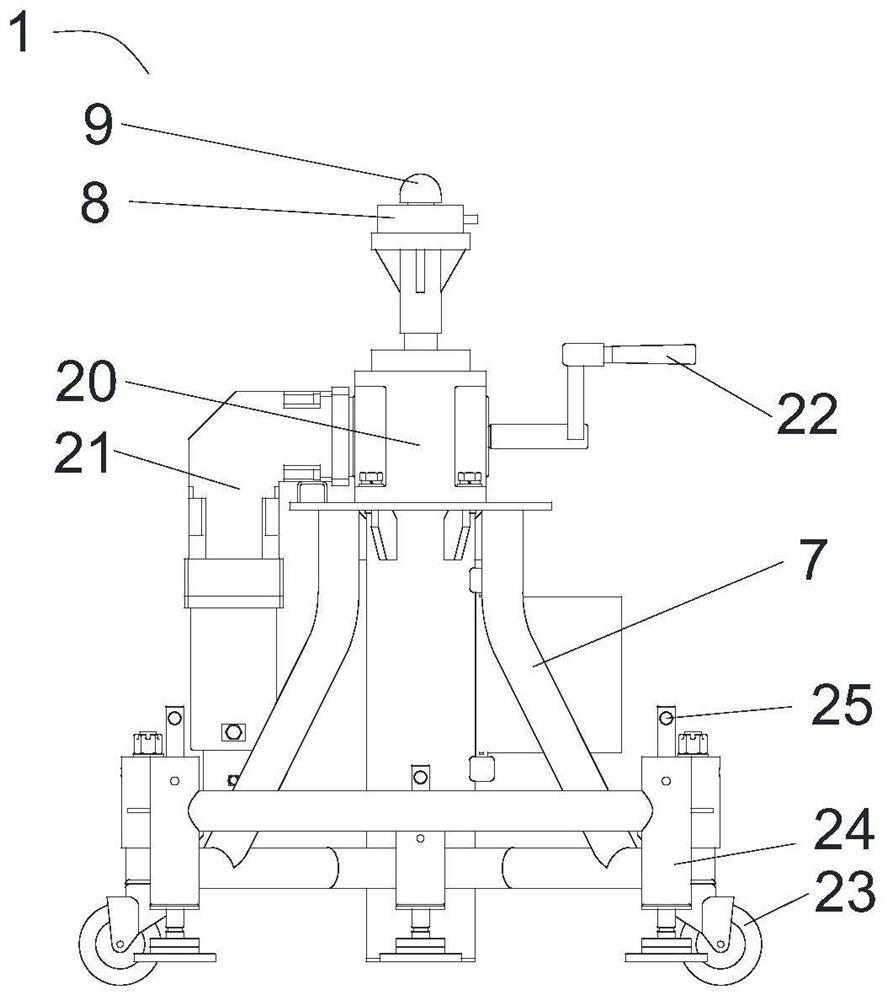

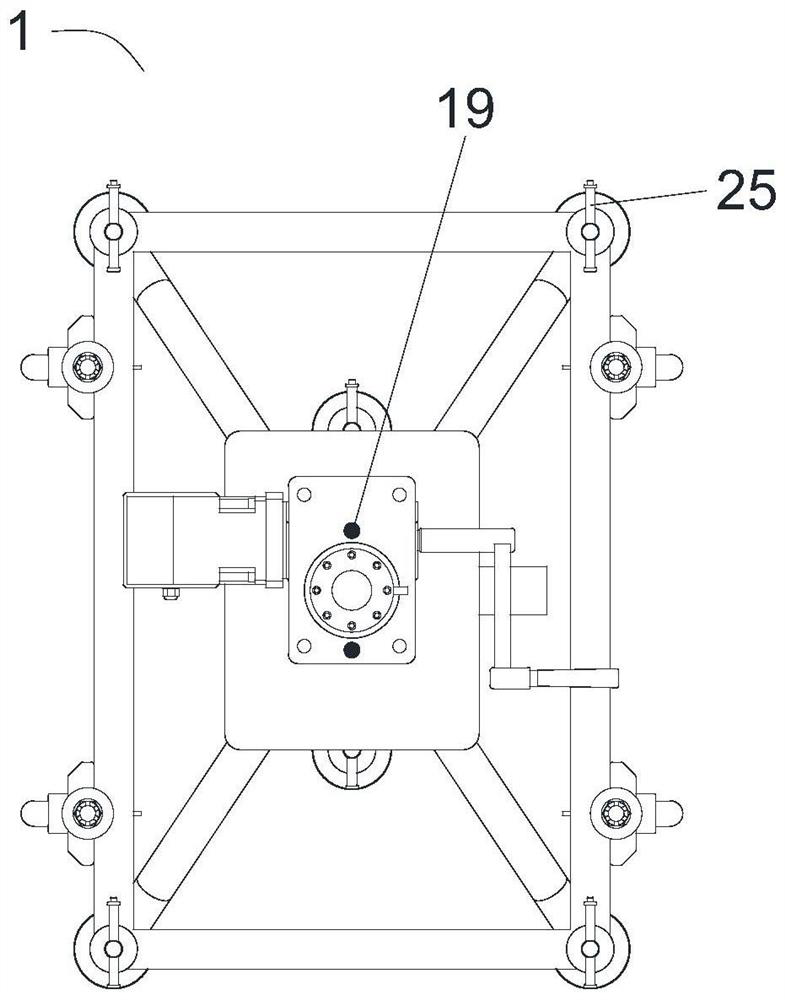

[0028] like Figure 1 to Figure 7 As shown, a multi-type aircraft weight center of gravity automatic measurement device includes a front servo lift leveling device 1, an inclination sensor 2, a tool cart 3, a rear servo lift leveling device 4 and a computer 5, and the inclination sensor 2 is installed on On the aircraft fuselage pitch reference plane, an electric control cabinet is built in the tool trolley 3, measurement management software is installed on the computer 5, the computer 5 is electrically connected to the electric control cabinet, the front servo lifting leveling device 1 and the rear servo lifting leveling device 1 The leveling devices 4 are all provided with a signal converter 6, and the inclination sensor 2, the signal converter 6, and the electric control cabinet are electrically connected in sequence. The attitude state of the aircraft can be obtained directly through the inclination sensor 2. Compared with the prior art, the aircraft attitude is obtained b...

Embodiment 2

[0039] like Figure 8 As shown, on the basis of the structure of Embodiment 1, the structure of the front servo lifting and leveling device 1 has the following changes:

[0040] In this embodiment, an anti-lateral force mechanism 11 is also provided between the bracket 7 and the load cell 8 of the front servo lifting and leveling device 1, and when lifting the top socket of the aircraft head, the anti-rolling force is improved. At the same time, it has a certain automatic alignment function, which reduces the requirements for the tester's operating skills, makes the operation easier and safer, and improves the accuracy and efficiency of the test.

[0041] When the multi-type aircraft weight and center of gravity automatic measurement device provided by this application is working, the front servo lift leveling device supports the front top socket of the aircraft head, the rear servo lift leveling device supports the rear reinforcement frame of the aircraft fuselage, and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com