Needle cylinder conical joint air tightness detector and injector processing system

A conical joint and air-tightness technology, which is applied in the direction of liquid-tightness measurement using liquid/vacuum degree, and detecting the appearance of fluid at the leakage point, etc., can solve the problems of poor detection timeliness, high professional requirements of operators, and increased production Cost and production risks and other issues to achieve the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The first embodiment of the air tightness tester for the syringe conical joint:

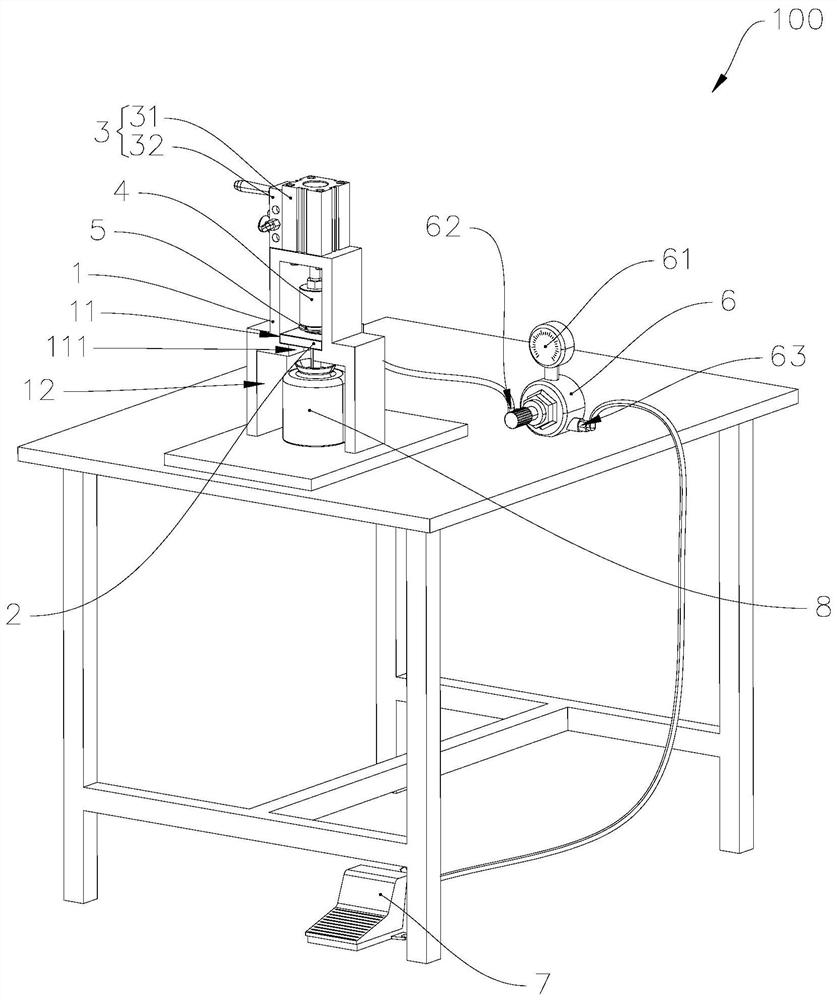

[0040] refer to figure 1 , the airtightness tester 100 of the needle barrel conical joint is used to test the airtightness of the needle barrel conical joint. The process of testing the syringe will not cause pollution to the production workshop. The airtightness tester 100 for the syringe cone joint includes a bracket 1 , a bearing plate 2 , a linear drive unit 3 , a pressure column 4 , a gasket 5 , a pressure regulating valve 6 , a valve switch 7 and a liquid storage bottle 8 .

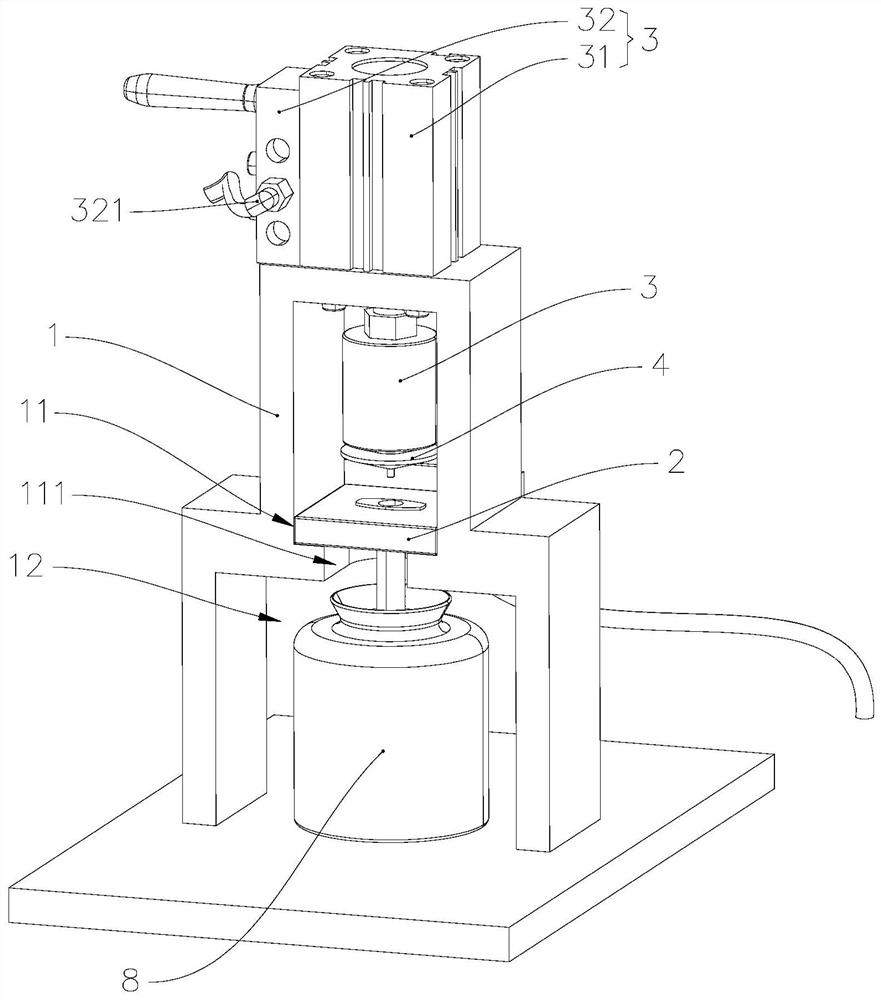

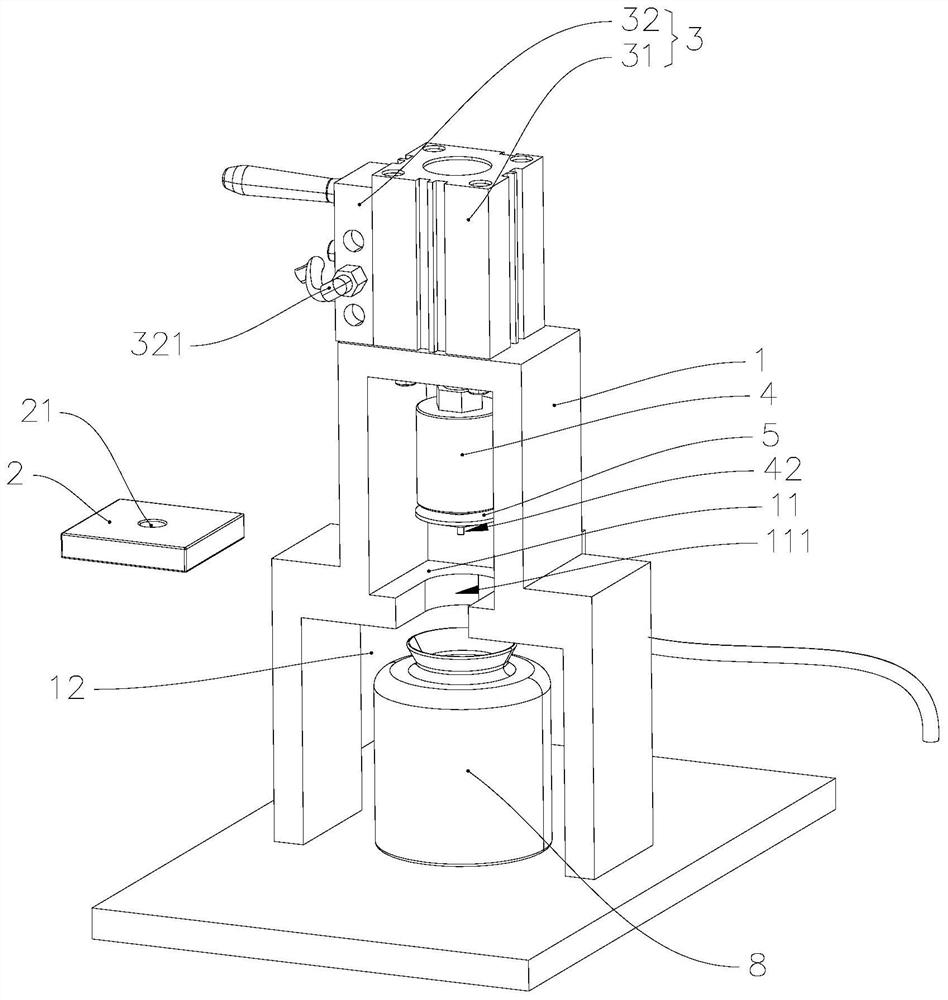

[0041] combine figure 2 and image 3 , in this embodiment, the bracket 1 and the bearing plate 2 are of a split structure, and the bracket 1 and the bearing plate 2 are detachably connected. Specifically, the bracket 1 is provided with an installation position 11 , and the bottom of the installation position 11 is provided with an opening 111 , and the opening 111 runs through the installation position 11 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com