Movable silicon tetrachloride product closed sampler

A technology of silicon tetrachloride and sampler, which is applied in sampling, sampling devices, instruments, etc., can solve the problems that silicon tetrachloride liquid can only be used once, and silicon tetrachloride liquid cannot be returned to the container again, so as to avoid chemical reaction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. The schematic embodiments and descriptions of the present invention are used to explain the present invention, but are not intended to limit the present invention.

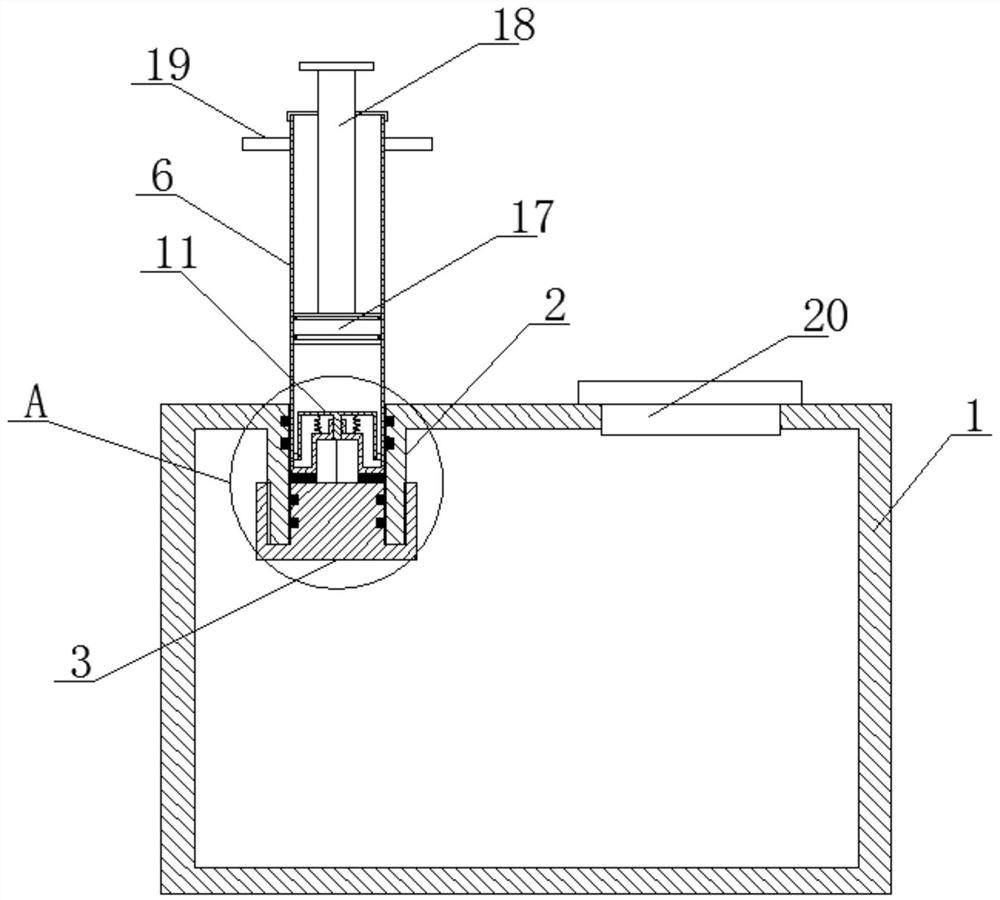

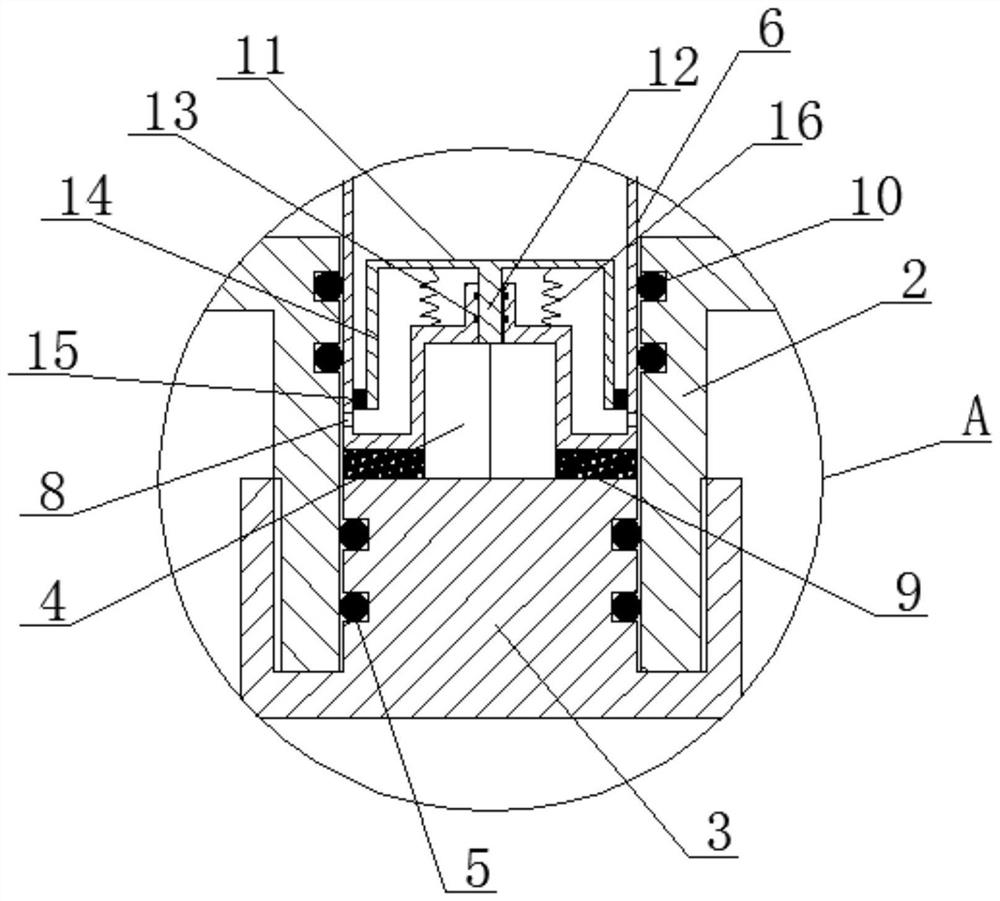

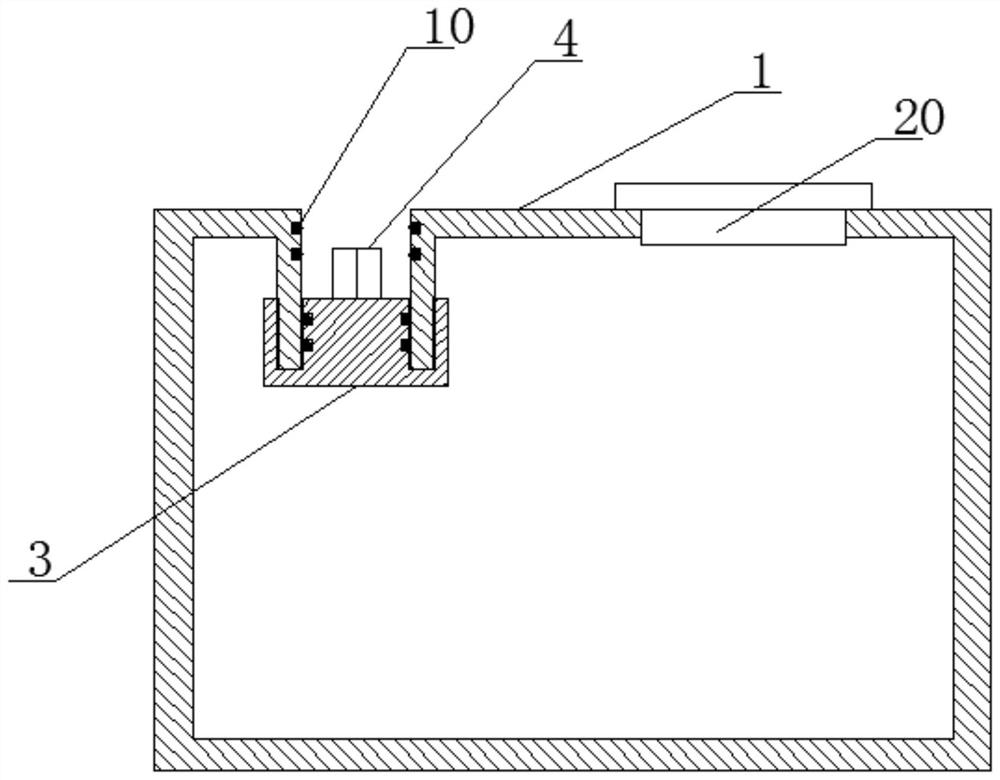

[0024] Such as Figure 1-7 As shown: the present invention includes a silicon tetrachloride container shell 1, a built-in sampling pipeline 2, a built-in pipeline cover 3, a pipeline cover block body 4, a sampling suction cylinder 6, a block body connecting cavity 7, and a suction cylinder inlet and outlet Liquid through hole 8, suction tube piston ring 17 and piston ring pull rod 18, the built-in sampling pipeline 2 is arranged on the inner side of the upper end of the silicon tetrachloride container shell 1, and the built-in pipeline cover 3 is located in the In the silicon tetrachloride container shell 1, and be threadedly connected between described built-in type sampling pipe 2,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com