Method for forming welding metal layer on device substrate and packaging method

A technology for welding metal and underlying metal layers, which is applied in the manufacturing of electric solid devices, semiconductor devices, and semiconductor/solid state devices, etc. It can solve the problem of easy occurrence of voids in the solder layer, improve roughness and film thickness uniformity, and reduce pollution. The content of the material and the effect of improving the heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] As mentioned in the background art, in order to solve the phenomenon of voids in the solder layer, current research directions and improvement ideas are basically aimed at the soldering process.

[0034] Different from the traditional solution, the present invention turns the research direction to the influence of the processing technology of the device substrate on the subsequent welding process. Specifically, the inventors of the present invention have found after a lot of research that the shape of the solder metal layer on the device substrate will also affect the void phenomenon in the solder layer to a certain extent.

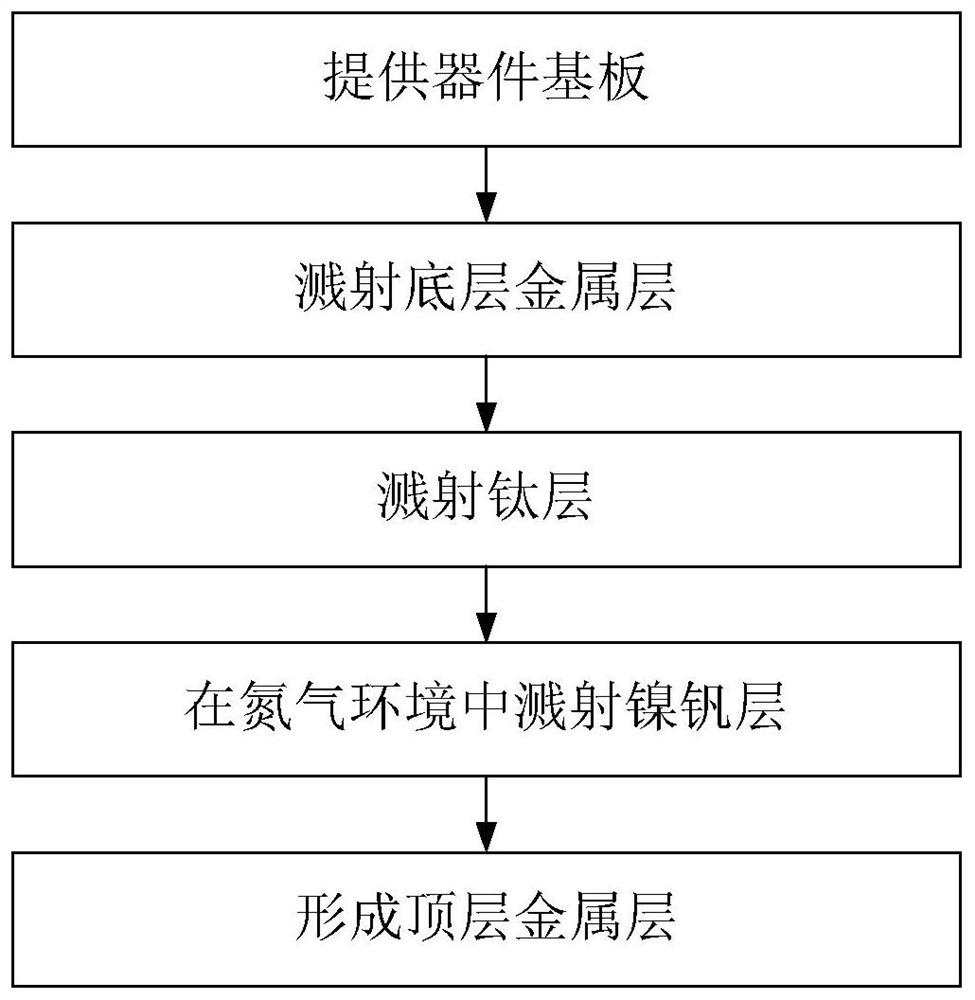

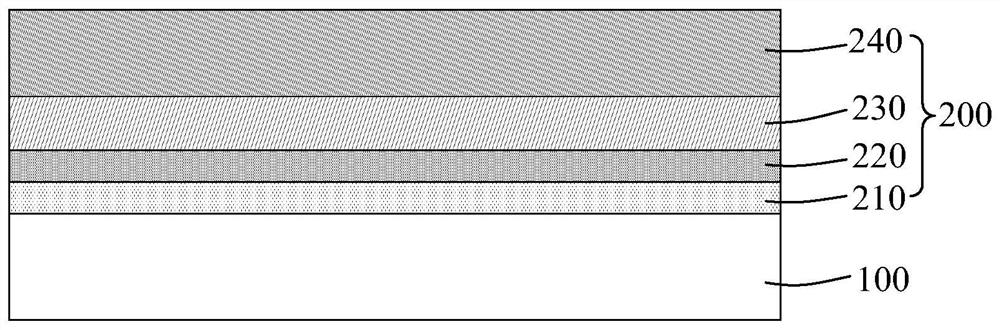

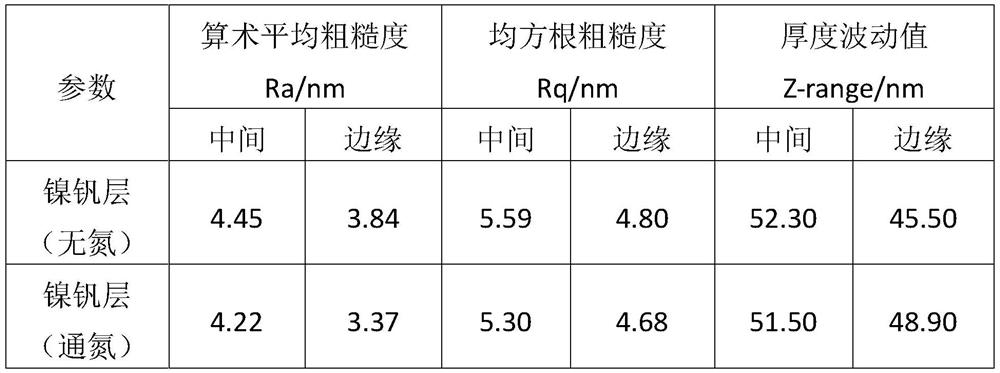

[0035] Thus, the present invention provides a method for forming a solder metal layer on a device substrate, for details, please refer to figure 1 As shown, the nickel vanadium layer in the solder metal layer is formed in a nitrogen atmosphere. That is, by improving the film quality of the nickel-vanadium layer, the overall shape of the solder met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com