Treating and recycling method of phenolic wastewater

A recycling and waste water technology, applied in water/sewage treatment, chemical instruments and methods, water treatment of special compounds, etc., can solve the problems of difficult separation, pollution of phenolic substances, high cost, etc., to reduce the content of pollutants, treat Low cost, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

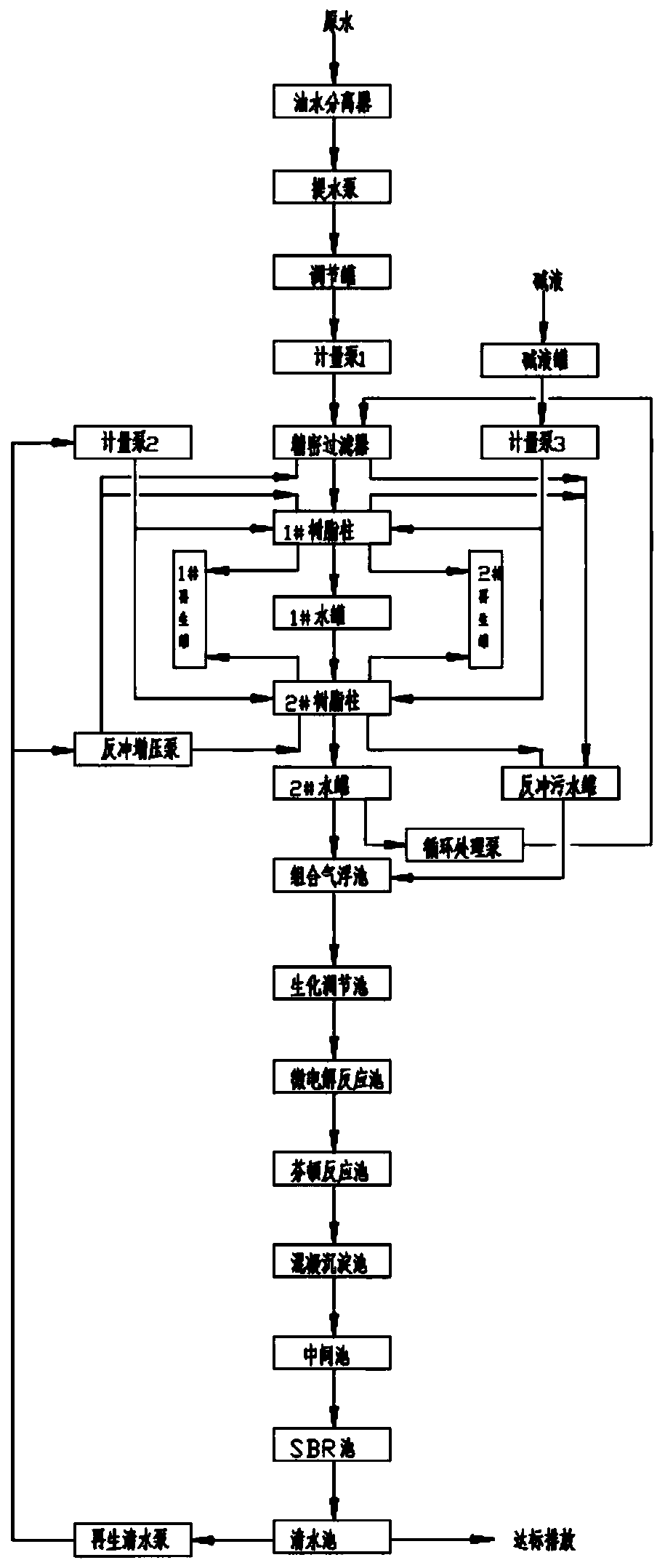

Image

Examples

Embodiment 1

[0029] A method for the treatment and resource utilization of phenolic waste water, comprising the following steps:

[0030] (1) Pass the phenolic wastewater into the oil-water separator for oil-water separation treatment, then pump it into the adjustment tank to adjust the water quality to a pH value of 5, and then filter the solid particles through a precision filter to obtain the filtrate; the precision filter The filter material is PPR filter cotton, the quantitative is 500g / m 2 , the precision filter specification is 1 meter in diameter and 2.5 meters in length;

[0031] (2) step (1) gained filtrate is passed through 1# resin column and 2# resin column successively, the phenol in the filtrate is adsorbed on the resin column; After the phenol content reaches 1000mg / L in the drainage after the resin column adsorption, to A NaOH solution with a concentration of 0.5% is introduced into the resin column, and the amount of introduction is 2.5 times the volume of the resin colu...

Embodiment 2

[0035] A method for the treatment and resource utilization of phenolic waste water, comprising the following steps:

[0036] (1) Pass the phenolic wastewater into the oil-water separator for oil-water separation treatment first, then pump it into the adjustment tank to adjust the water quality to a pH value of 3, and then filter the solid particles through a precision filter to obtain the filtrate; the precision filter The filter material is PPR filter cotton, the quantitative is 400g / m 2 , the precision filter specification is 1 meter in diameter and 2.5 meters in length;

[0037] (2) step (1) gained filtrate is passed through 1# resin column and 2# resin column successively, and the phenol in the filtrate is adsorbed on the resin column; A KOH solution with a concentration of 0.6% was introduced into the medium, and the amount of introduction was 2 times the volume of the resin column. The alkaline solution reacts with the phenolic substances in the resin column to form a sa...

Embodiment 3

[0041] A method for the treatment and resource utilization of phenolic waste water, comprising the following steps:

[0042] (1) Pass the phenolic wastewater into the oil-water separator for oil-water separation treatment, then pump it into the adjustment tank to adjust the water quality to a pH value of 4, and then filter the solid particles through a precision filter to obtain the filtrate; the precision filter The filter material is PPR filter cotton, the quantitative is 600g / m 2 , the precision filter specification is 1 meter in diameter and 2.5 meters in length;

[0043] (2) step (1) gained filtrate is passed through 1# resin column and 2# resin column successively, and the phenol in the filtrate is adsorbed on the resin column; A KOH solution with a concentration of 0.6% is passed through the column, and the amount passed through is 2.2 times the volume of the resin column. The alkaline solution reacts with the phenolic substances in the resin column to form a salt and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com