Coal tar wastewater demulsification and oil removal device

A technology for coal tar and waste water, applied in grease/oily substance/float removal device, water/sewage treatment, natural water treatment, etc., can solve the big economic burden, violate clean production, dilute waste water and increase the processing load of biochemical station, etc. problems, to achieve the effect of reducing processing costs, reducing the content of pollutants, and high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

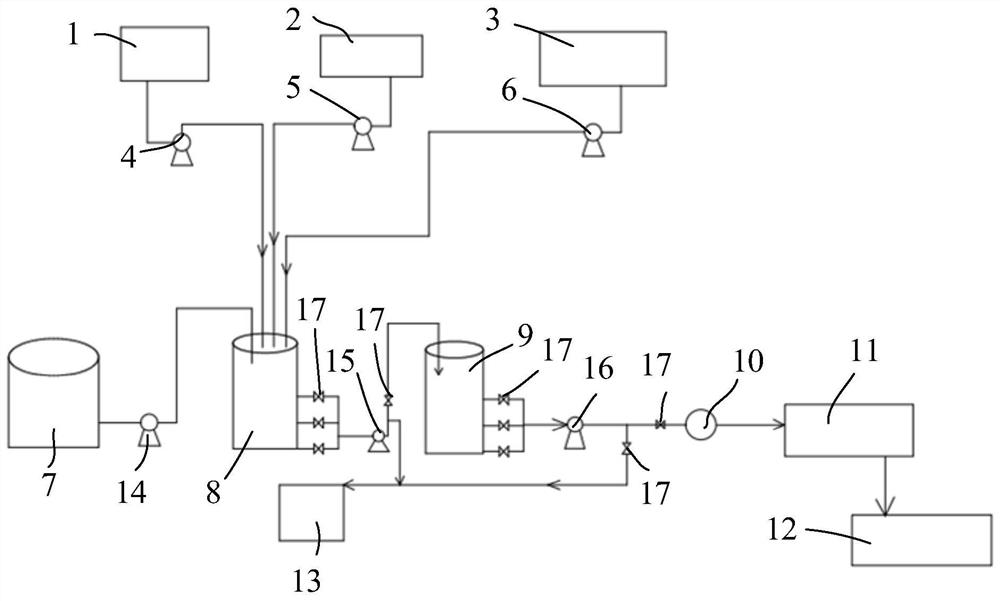

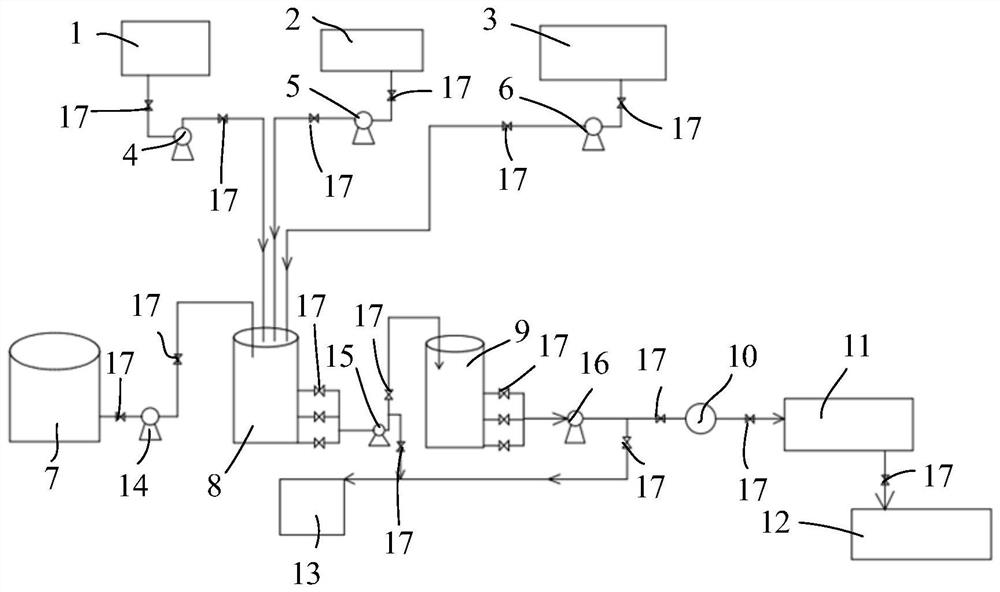

[0025] Such as figure 1 As shown, a coal tar wastewater demulsification and oil removal device in this embodiment includes a hydrochloric acid storage tank 1, a flocculant storage tank 2, a demulsifier storage tank 3, a coal tar wastewater tank 7, a primary separation tank 8 and a secondary The separation tank 9; the coal tar waste water tank 7 is connected to the primary separation tank 8 through a pipeline, the primary separation tank 8 is connected to the secondary separation tank 9 through a pipeline, and the hydrochloric acid storage tank 1, the flocculant storage tank 2 and the demulsifier storage tank 3 pass through the The pipeline is connected with the primary separation tank 8.

[0026] Specifically, the secondary separation tank 9 is connected to the stripping and dephenolizing device 11 through a pipeline, and the treated wastewater from the stripping and dephenolizing device 11 is discharged into the sewage treatment system 12 .

[0027] The technical effect achi...

Embodiment 2

[0029] Such as figure 1 As shown, a coal tar wastewater demulsification and oil removal device in this embodiment includes all the technical features in Embodiment 1. In addition, it also includes a bag filter 10 and a stripping dephenolization device 11. The bag filter The device 10 is arranged on the pipeline between the secondary separation tank 9 and the stripping and dephenolizing device 11.

[0030] Optionally, it also includes a first dosing pump 4, a second dosing pump 5 and a third dosing pump 6, the first dosing pump 4 is arranged on the pipeline between the hydrochloric acid storage tank 1 and the primary separation tank 8, The second dosing pump 5 is arranged on the pipeline between the flocculant storage tank 2 and the primary separation tank 8 , and the third dosing pump 6 is arranged on the pipeline between the demulsifier storage tank 3 and the primary separation tank 8 .

[0031] The beneficial effects in this embodiment are: by setting the bag filter 10, the...

Embodiment 3

[0033] Such as figure 1 As shown, a coal tar wastewater demulsification and degreasing device in this embodiment includes all the technical features in Embodiment 2. In addition, it also includes a first delivery pump 14, and the first delivery pump 14 is arranged on the coal On the pipeline between the tar waste water tank 7 and the primary separation tank 8.

[0034] Optionally, a second delivery pump 15 is also included, and the second delivery pump 15 is arranged on the pipeline between the primary separation tank 8 and the secondary separation tank 9 .

[0035] Optionally, a third delivery pump 16 is also included, and the third delivery pump 16 is arranged on the pipeline between the secondary separation tank 9 and the bag filter 10 .

[0036] The beneficial effects in this embodiment are: by setting the first delivery pump 14, the rapid delivery of the waste water in the coal tar wastewater tank 7 to the primary separation tank 8 is realized; by setting the second deli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com