Wind power boosting rotor ventilation and heat dissipation device

A technology for ventilation, heat dissipation and boosting, which is applied in cooling/ventilation devices, cooling/ventilation/heating renovation, pump devices, etc., and can solve the problems that affect the continuous operation of the rotor, affect the stability of the motor, and complex heat dissipation schemes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

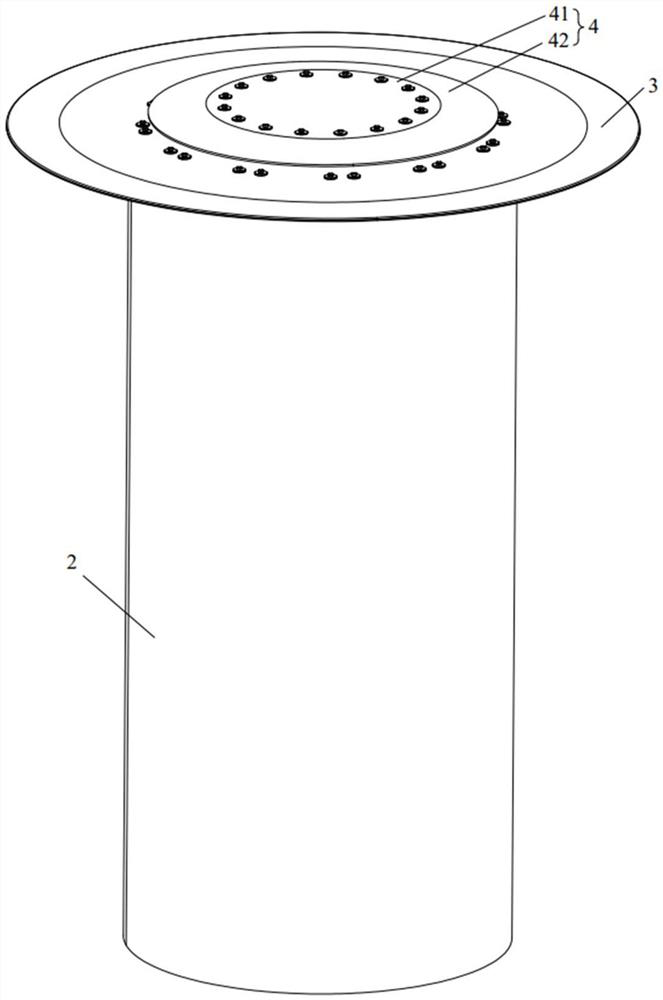

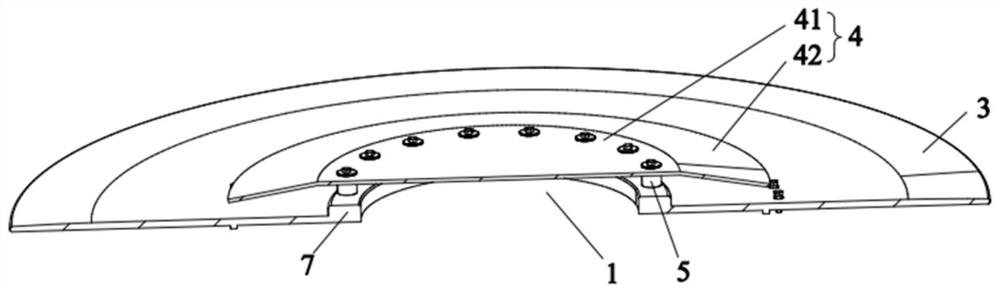

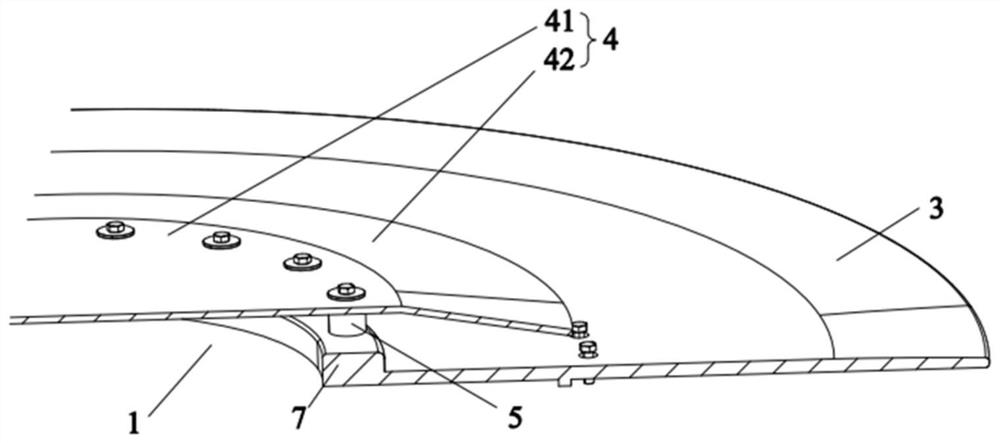

[0045] like figure 1 As shown, this embodiment provides a wind-assisted rotor ventilation and heat dissipation device, and the wind-assisted rotor ventilation and heat dissipation device includes a cylinder body 2 , a top cover 3 and a rain shield 4 . Specifically, such as figure 2 and image 3 As shown, the top cover 3 is covered and arranged on the top of the cylinder body 2 , and the manhole 1 is opened on the top cover 3 , and the manhole 1 communicates with the inner cavity of the cylinder body 2 . The rain shielding plate 4 is covered and arranged above the manhole 1, and the rain shielding plate 4 and the top cover 3 are spaced apart to form a heat dissipation gap communicated with the outside atmosphere. like Figure 4 As shown, in this embodiment, by setting the wind-assisted rotor ventilation and heat dissipation device, the heat inside the cylinder body 2 is dissipated to the outside atmosphere through the heat dissipation gap under the action of the exhaust fan...

Embodiment 2

[0053] This embodiment proposes a wind-assisted rotor ventilation and heat dissipation device, such as Figure 5 and Image 6 As shown, the difference between the wind-assisted rotor ventilation and heat dissipation device and the wind-assisted rotor ventilation and heat-radiation device in the first embodiment is only that the wind-assisted rotor ventilation and heat dissipation device in this embodiment has a reinforcing component 6 .

[0054] In order to further improve the structural strength of the flashing board 4 to cope with bad weather, the wind-assisted rotor ventilation and heat dissipation device in this embodiment may further include a reinforcement assembly 6 . like Figure 5 and Image 6 As shown, the reinforcement assembly 6 is provided on the lower surface of the flasher 4 between the flasher 4 and the top cover 3 . Specifically, as Figure 7 As shown, the reinforcing assembly 6 includes an inner lining plate 61 and a reinforcing rib 62, and the inner lini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com