Full-automatic production line for fruit and vegetable juice production

An assembly line, fully automatic technology, applied in the direction of juice extraction, fixed filter element filter, food forming, etc., can solve the problem of waste of fruits and vegetables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

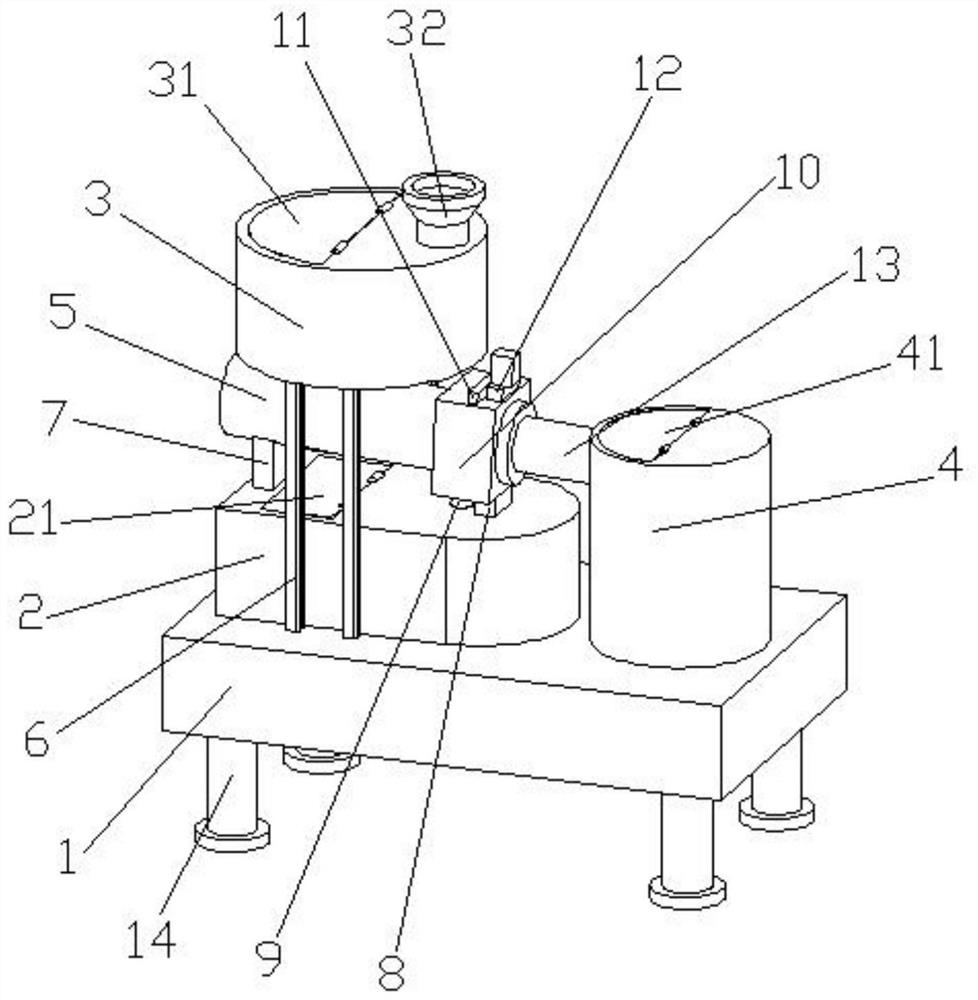

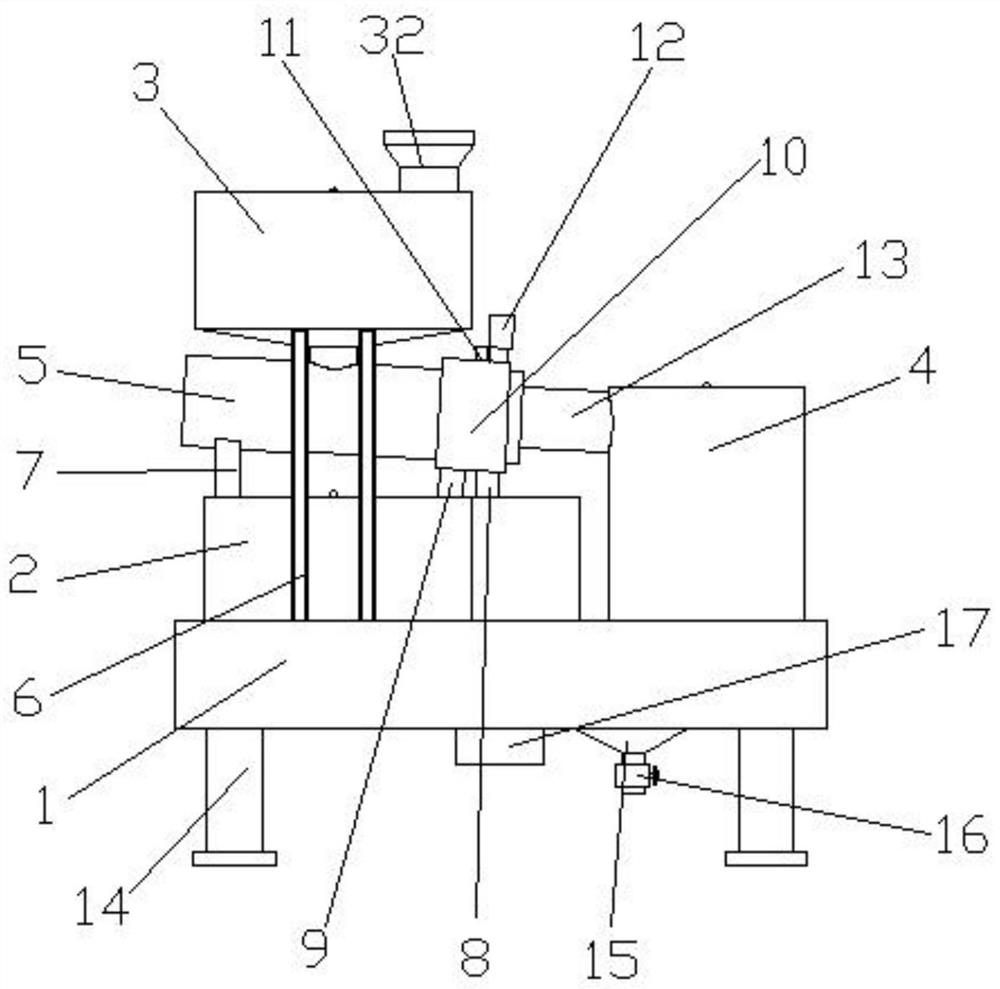

[0033] refer to Figure 1-4 As shown, a fully automatic assembly line for fruit and vegetable juice production includes a mixing box 1, an additive adding box 2 and a pomace box 4 are arranged on the mixing box 1, a crushing box 3 is arranged above the additive adding box 2, and a crushing box 3 is arranged on the additive adding box 1. A solid-liquid separation cylinder 5 is provided between the box 2 and the smashing box 3. The first fixed plate 7 and the second fixed plate 8 are fixedly connected with the solid-liquid separation cylinder 5 above the additive addition box 2. The first fixed plate 7 and the second fixed plate Two fixing plates 8 are arranged between the additive addition box 2 and the solid-liquid separation cylinder 5, and a set of support columns 6 are fixed on the lower side of the smashing box 3, and the lower ends of the support columns 6 are fixedly connected above the mixing box 1.

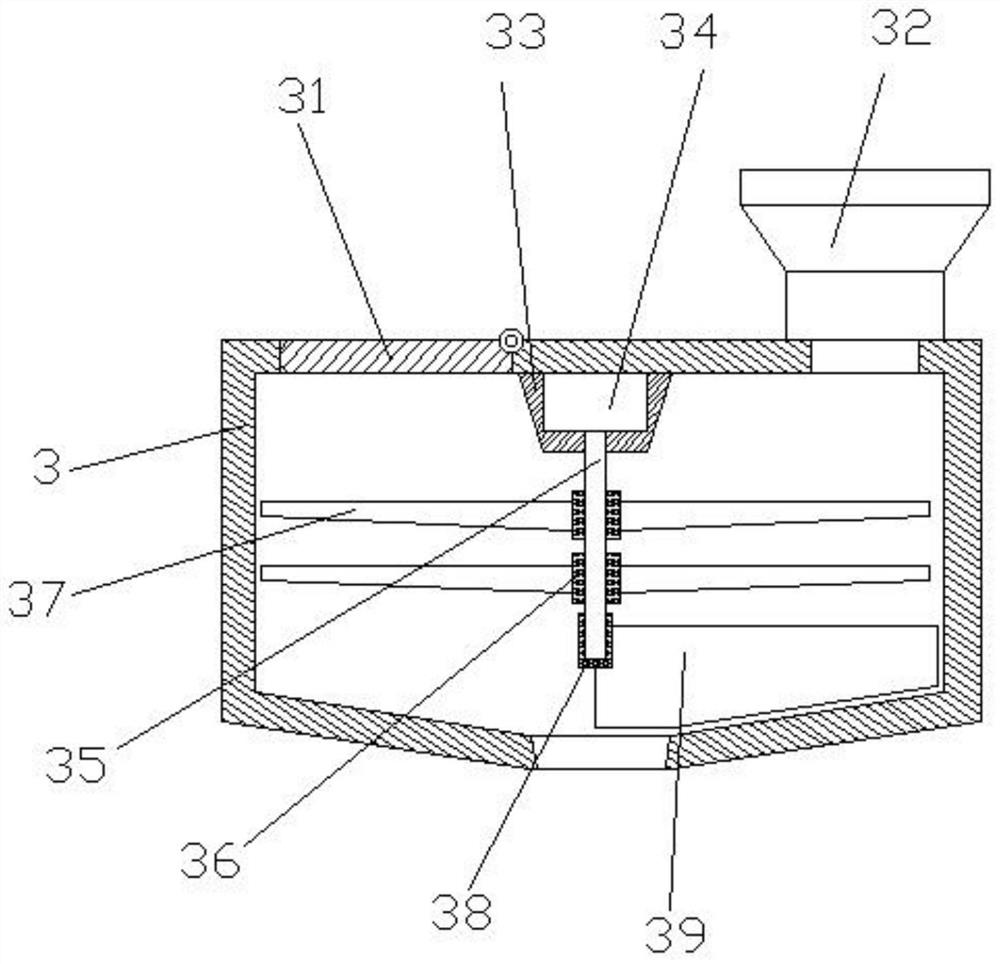

[0034] The first box door 31 is hinged on the broken box 3, and the f...

Embodiment 2

[0041] refer to figure 1 , figure 2 , Figure 5 and Figure 6 As shown, a fully automatic assembly line for fruit and vegetable juice production includes a mixing box 1, an additive adding box 2 and a pomace box 4 are arranged on the mixing box 1, a crushing box 3 is arranged above the additive adding box 2, and a crushing box 3 is arranged on the additive adding box 1. A solid-liquid separation cylinder 5 is provided between the box 2 and the smashing box 3, and the first fixed plate 7 and the second fixed plate 8 are fixedly connected with the solid-liquid separation cylinder 5 above the additive addition box 2, and the first fixed plate 7 is connected to the second fixed plate. The second fixing plate 8 is arranged between the additive addition box 2 and the solid-liquid separation cylinder 5 , a group of support columns 6 are fixed on the lower side of the crushing box 3 , and the lower ends of the support columns 6 are fixedly connected above the mixing box 1 .

[004...

Embodiment 3

[0046] refer to figure 1 , figure 2 , image 3 , Figure 5 , Figure 6 and Figure 7 As shown, a fully automatic assembly line for fruit and vegetable juice production includes a mixing box 1, an additive adding box 2 and a pomace box 4 are arranged on the mixing box 1, a crushing box 3 is arranged above the additive adding box 2, and a crushing box 3 is arranged on the additive adding box 1. A solid-liquid separation cylinder 5 is provided between the box 2 and the smashing box 3, and the first fixed plate 7 and the second fixed plate 8 are fixedly connected to the solid-liquid separation cylinder 5 above the additive addition box 2, and the first fixed plate 7 and the second fixed plate Two fixing plates 8 are arranged between the additive addition box 2 and the solid-liquid separation cylinder 5, and a set of support columns 6 are fixed on the lower side of the smashing box 3, and the lower ends of the support columns 6 are fixedly connected above the mixing box 1.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com