Vacuum low-temperature dehydration equipment with monitoring device

A monitoring device, vacuum and low temperature technology, applied in evaporator regulation/control, sub-atmospheric process, method of chemically changing substances by atmospheric pressure, etc. Processing status, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

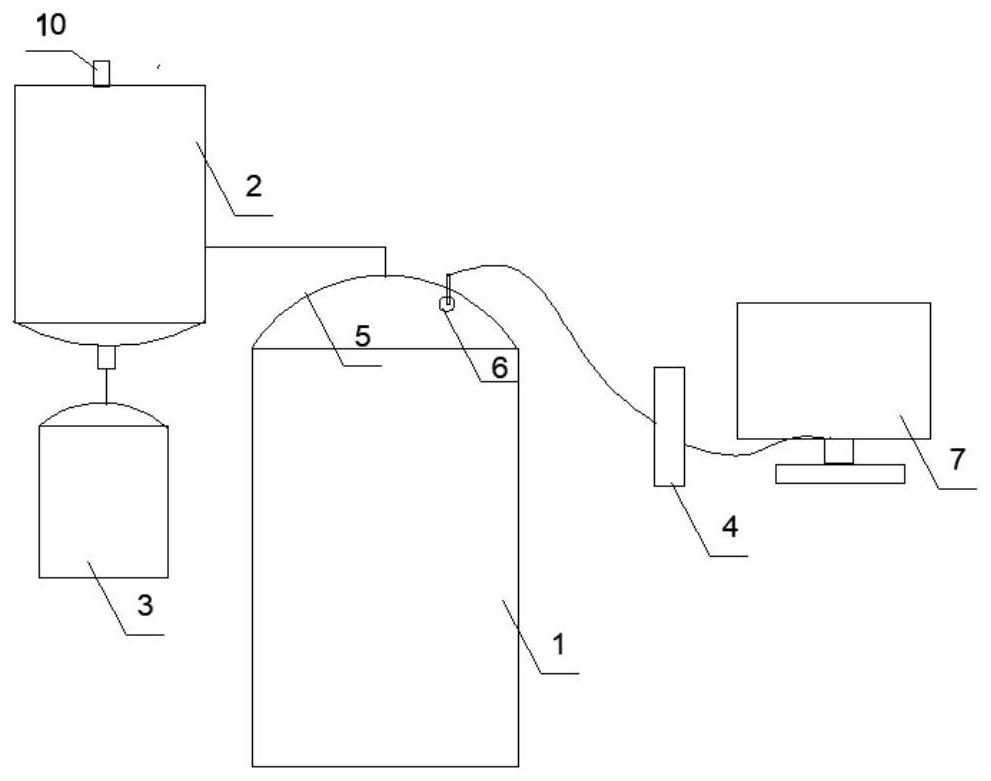

[0017] Such as figure 1 As shown, a vacuum low-temperature dehydration equipment with a monitoring device includes a dehydration reactor 1, a condensation device 2, a condensed water collection device 3 and a monitoring device. The dehydration reactor is provided with a cover 5, and the cover The air outlet on the top is connected to the air inlet of the condensing device through a pipeline, and the drain of the condensing device is connected to the water inlet of the condensed water collecting device through a pipeline. The monitoring device includes a camera 6, a PLC controller 4 and a display 7, The camera is arranged on the cover in the dehydration reactor, and the camera and the display are electrically connected with the PLC controller.

[0018] The model of the PLC controller used in this embodiment is S7-400, which is suitable for the field of medium and high performance automation control, with powerful performance and simple operation.

Embodiment 2

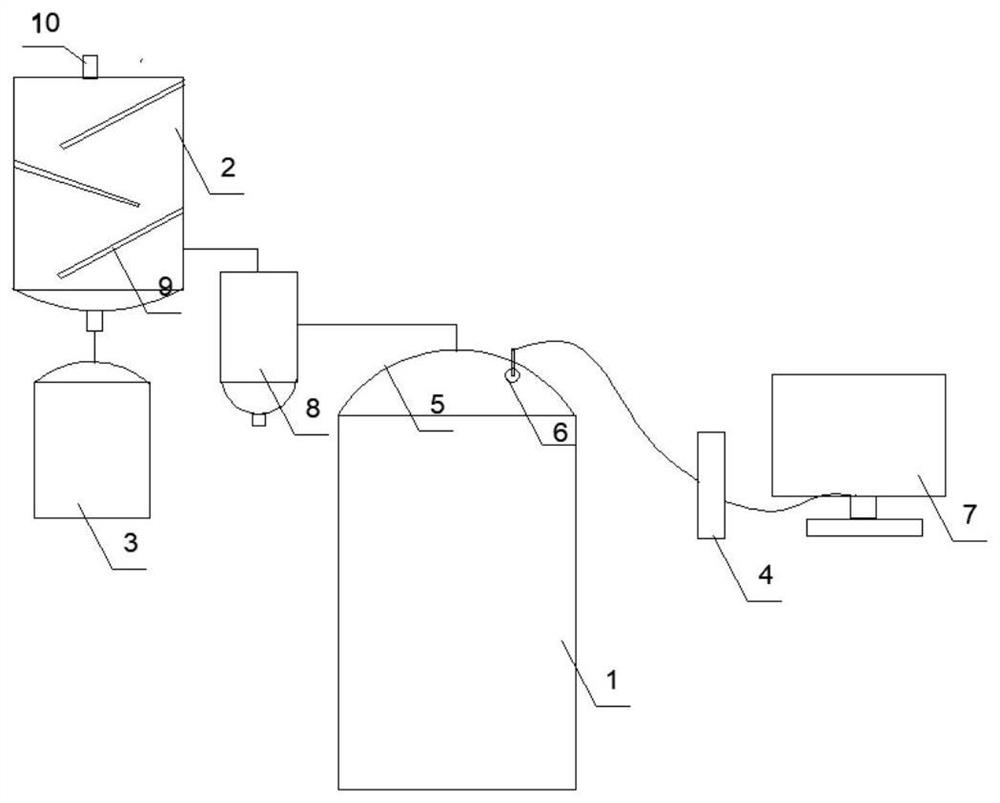

[0020] Such as figure 2 As shown, a vacuum low-temperature dehydration equipment with a monitoring device includes a dehydration reactor 1, a condensation device 2, a condensed water collection device 3 and a monitoring device. The dehydration reactor is provided with a cover 5, and the cover The air outlet on the top is connected to the air inlet of the condensing device through a pipeline, and the drain of the condensing device is connected to the water inlet of the condensed water collecting device through a pipeline. The monitoring device includes a camera 6, a PLC controller 4 and a display 7, The camera is arranged on the cover in the dehydration reactor, and the camera and the display are electrically connected with the PLC controller.

[0021] An oil-gas separator 8 is arranged between the air outlet on the cover and the air inlet of the condensing device, the air inlet of the oil-air separator is connected with the air outlet on the cover through a pipeline, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com