Yellow River sand ultra-high-performance concrete and preparation method thereof

An ultra-high performance, concrete technology, applied in the field of building materials, can solve the problems of dust pollution, ecological damage, and low strength of Yellow River sand concrete, and achieve the effects of reducing environmental impact, increasing storage capacity, and reducing siltation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036]1. Raw materials

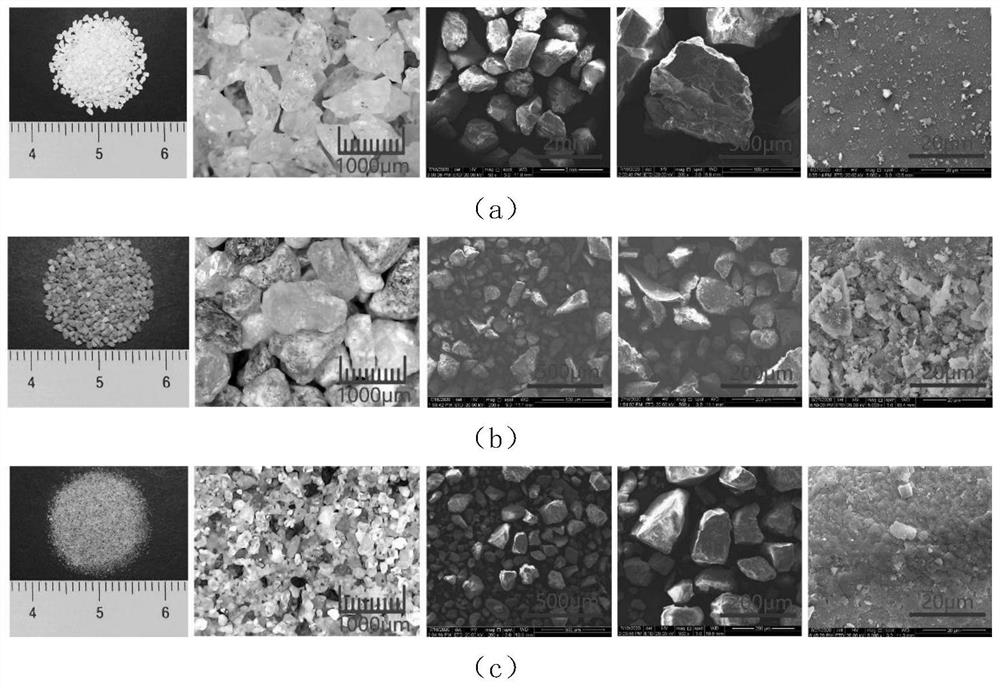

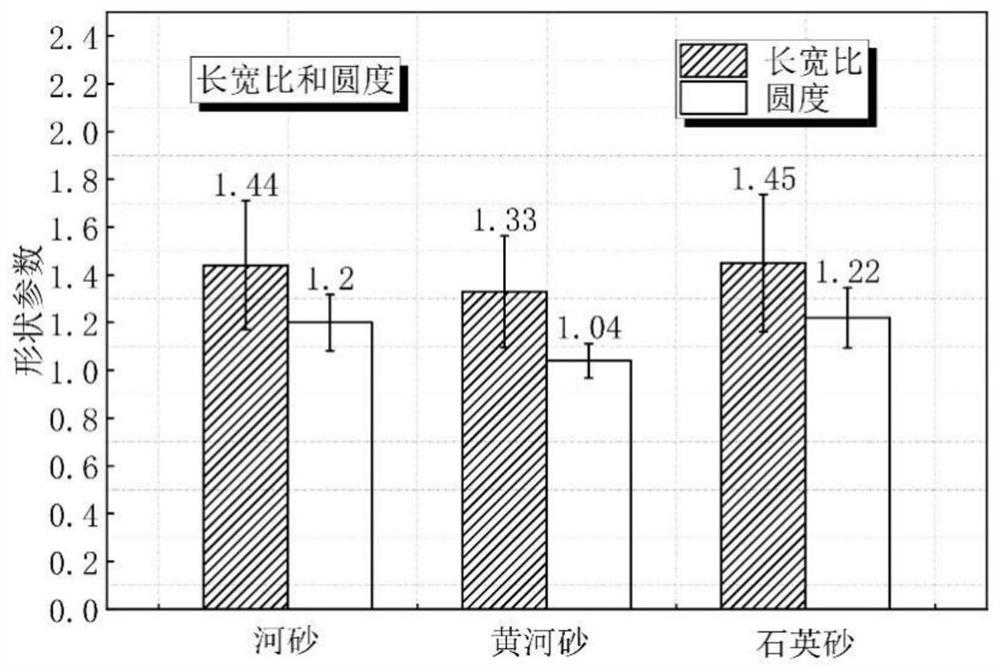

[0037]In the embodiment of the present invention, the materials used are first-grade fly ash (Rongchangsheng Environmental Protection Material Factory), microsilica fume (Lvmingyuan Environmental Protection Material Factory), cement (Boai Jinyu PO52.5), 30% curing amount Water reducing agent (Subbot), river sand with a particle size of 0.6-1.4mm, 52.5 ordinary Portland cement, yellow river sand with a particle size of 0-0.6mm, particle size of 0.45-1mm and 0.18-0.45mm Quartz sand. The raw material components are shown in Table 1.

[0038]Table 1 Ingredients of raw materials

[0039]

[0040]2. The ratio of raw materials

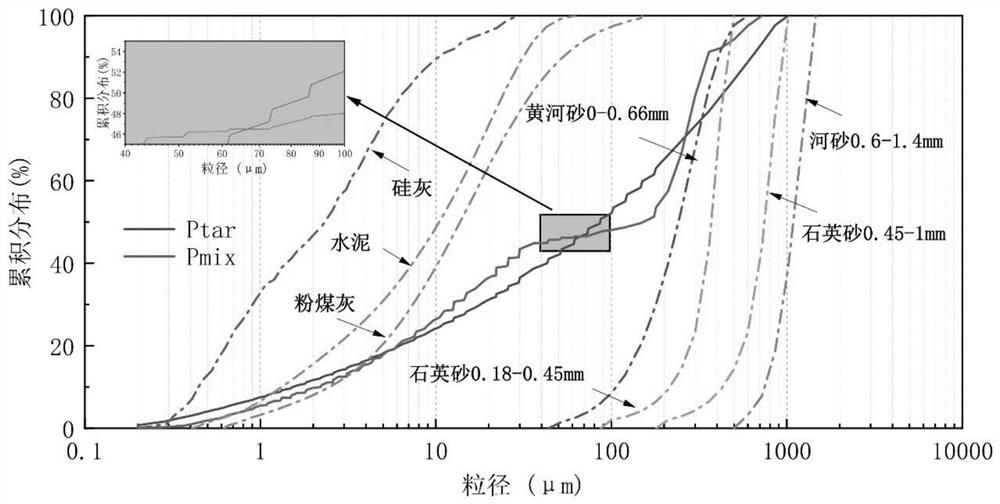

[0041]In order to make the various performances of UHPC more superior, the stacking framework is more dense. Through the revised A&A model, the particle size distribution curve of the mixed materials is close to the target curve, so as to realize the compact structure of UHPC, which is the key factor for the ultra-high performance of concrete. When the la...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap