Magnesian binding agent and method for preparing refractory material by using magnesian binding agent

A magnesia binder and refractory technology, which is applied in the field of magnesia binder and the preparation of refractory materials by using magnesia binder, can solve problems such as low strength, and achieve the effects of improving bonding strength, increasing strength and prolonging storage time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

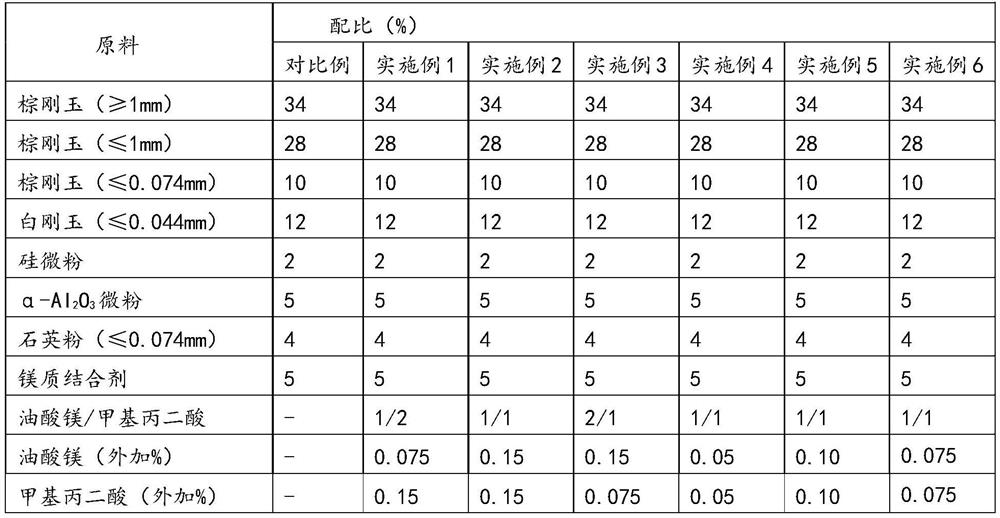

[0026] In this embodiment, a corundum castable refractory material is used, and a magnesia binder is used as a binder. The composition of raw materials is shown in Table 1.

[0027] Table 1 raw material ratio composition

[0028]

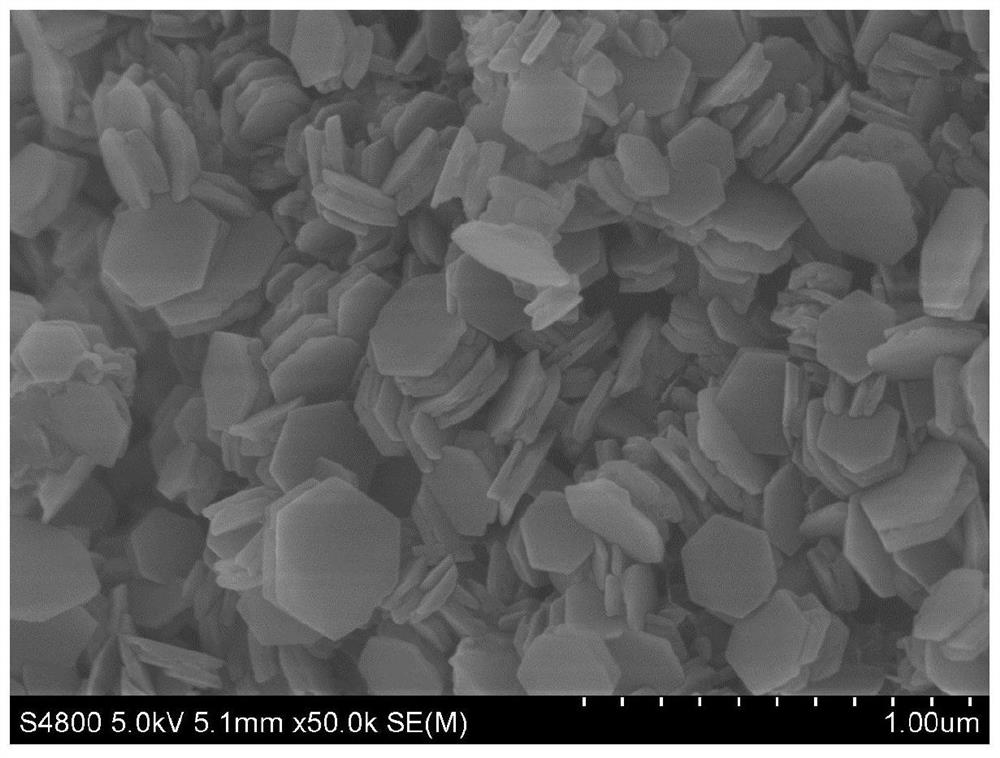

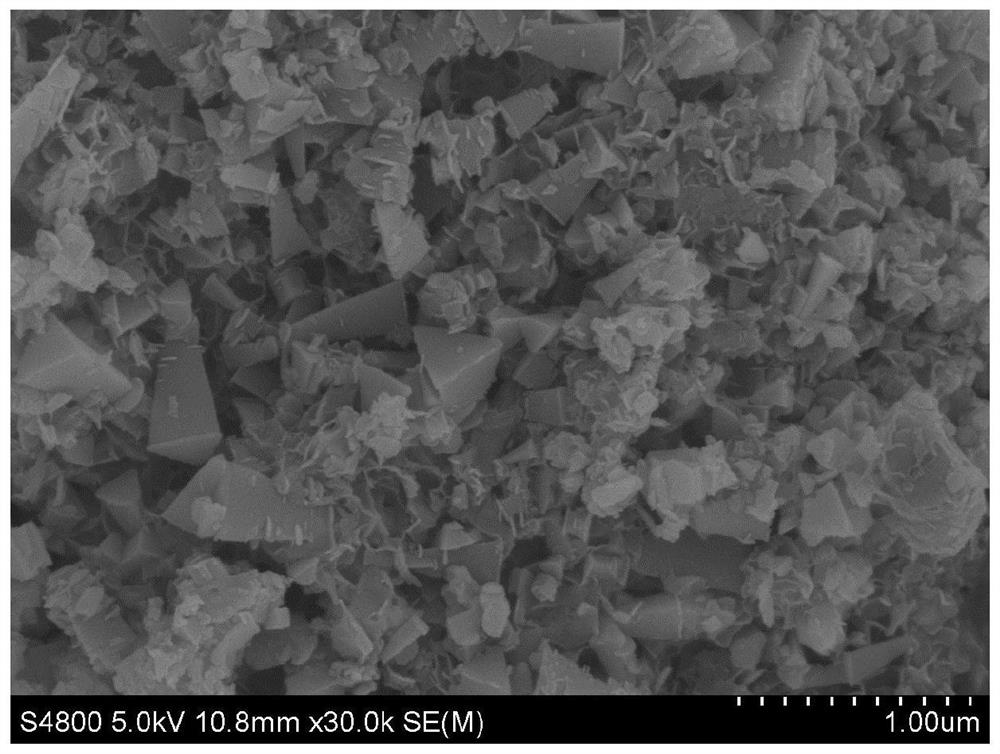

[0029] Weigh by raw material proportion shown in Table 1, proportioning total weight is 1000g. Put the above raw materials into a mixer and stir evenly, then add 70g of water, continue stirring for 10 minutes to form a slurry, and then inject the slurry into a mold for molding. After forming, the mold is naturally cured for 24 hours, and then the mold is demoulded. After demoulding, the natural curing is continued for 24 hours, and then baked in an oven at 200 ° C for 24 hours. After drying, the compressive strength of the sample was measured according to GB / T5072-2008 "Test Method for Compressive Strength at Normal Temperature of Refractory Materials", and the microstructure of the bonded phase of the sample section was observed with an electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com