A kind of hybrid steel and heat treatment method thereof

A bar and austenite technology, applied in the field of heat treatment, can solve problems such as lack of exploration of heat treatment process, achieve the effect of avoiding red hot brittleness, high corrosion resistance, and realizing efficient utilization of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

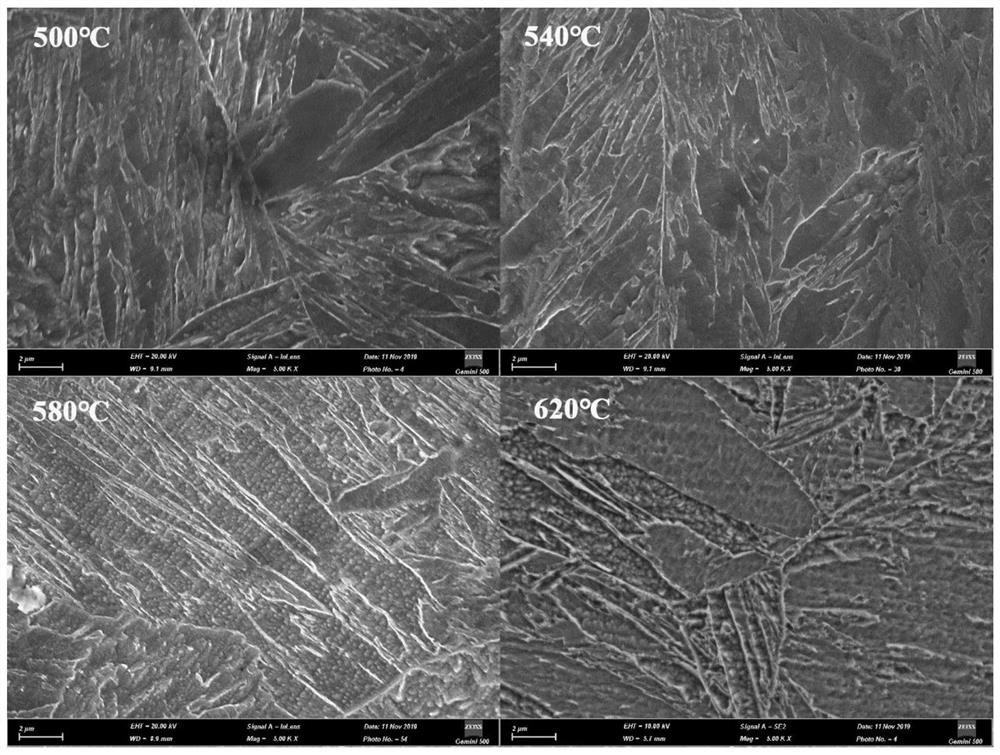

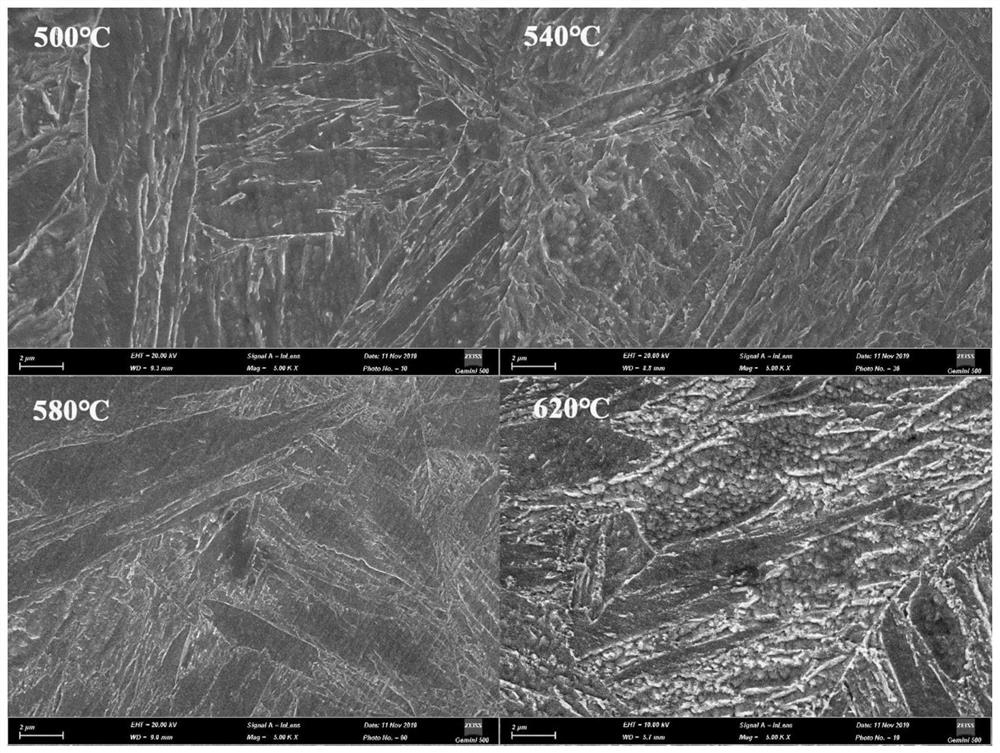

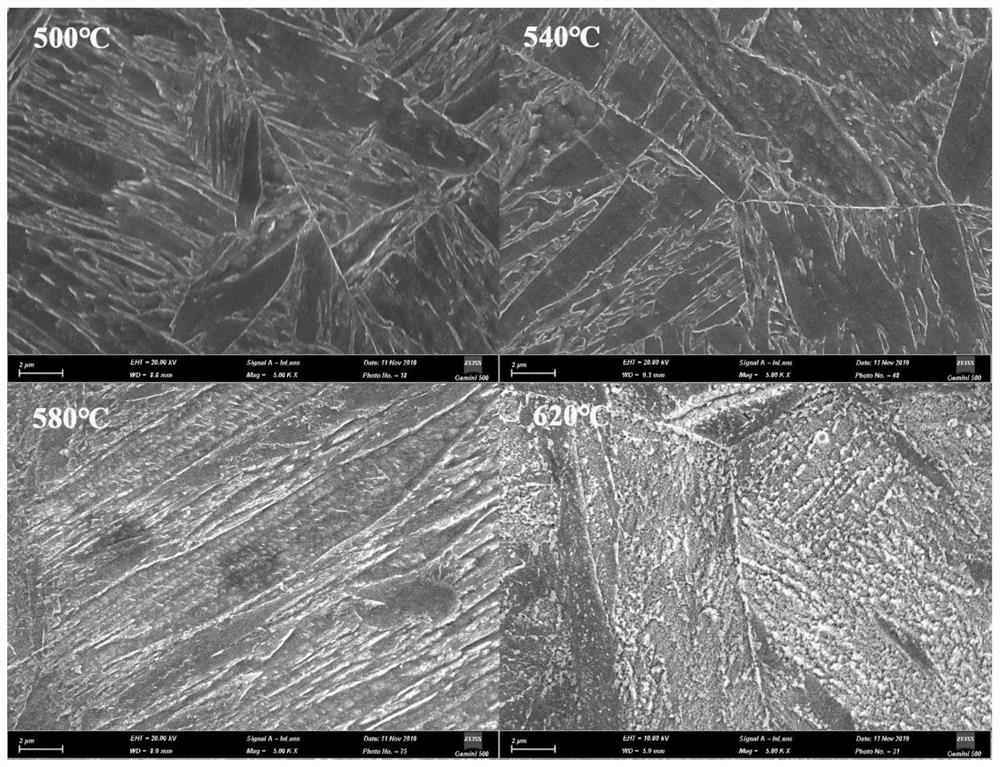

Embodiment 1

[0032] This embodiment provides a hybrid steel, including the following components in weight percentage: C 0.11%, Si0.13%, Mn0.30%, Cr4.76%, Ni5.90%, V0.48%, Nb0.002%, Mo0.68%, Al1.9%, P0.01%, S0.01%, and the rest is Fe.

[0033] This embodiment provides a method for heat treating the above hybrid steel, comprising the following steps:

[0034] Step 1. According to the composition of the mixed steel, it is refined into a bar with a diameter of 60mm, and the bar is taken to a warm loft and kept at 800°C for 180min; in this embodiment, the austenite transformation start temperature Ac1= 723-10.7Mn-16.9Ni+29.1Si+23.3Cr, Ac1=734°C;

[0035] Step 2: furnace cool the rod after step 1 to 600°C at a cooling rate of 20°C / h, air cool the rod cooled to 600°C to room temperature, and complete the softening annealing treatment; the room temperature is 25°C;

[0036] Step 3. Measure step 2. After air-cooling to room temperature, the diameter of the bar is 60mm, and then take the method of...

Embodiment 2

[0039] This embodiment is the same as Embodiment 1, except that the heating is performed to 540° C. in Step 4.

Embodiment 3

[0041] This embodiment is the same as Embodiment 1, except that the heating is performed to 580° C. in Step 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com