Control method and system for improving frequency and power of free piston linear generator

A technology of linear generators and control methods, applied in free piston engines, engine control, machines/engines, etc., can solve the problems of less than 1.1kW output power, low maximum moving speed of movers, and low overall operating frequency, and achieve improved The effect of improving the movement frequency of the mover, reducing the pump air loss and increasing the working frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

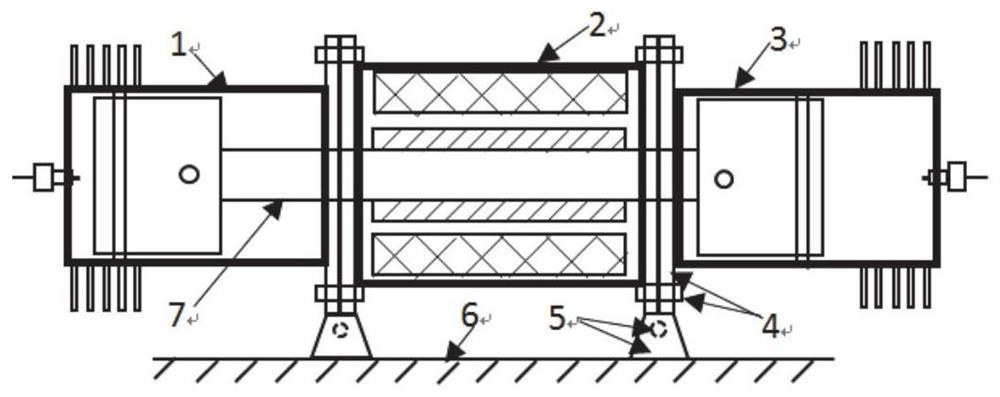

[0038] This embodiment discloses a control method for increasing the frequency and power of a free-piston linear generator, including:

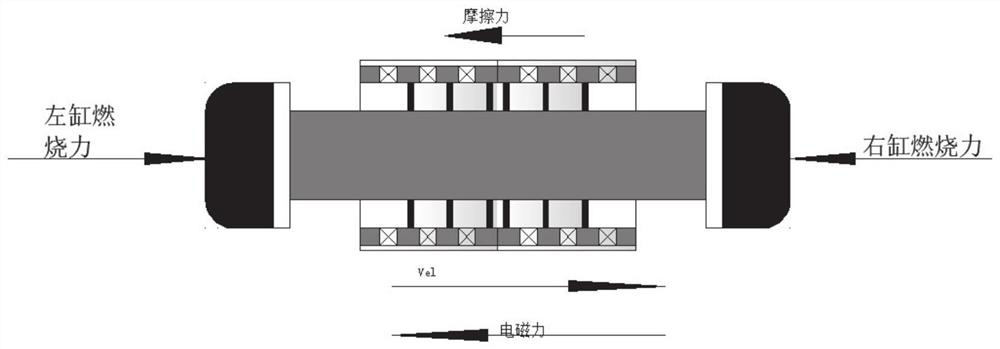

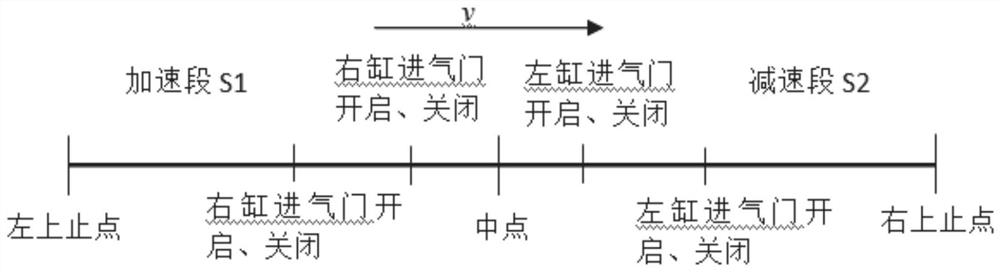

[0039] Moving the mover from the top dead center position on one side to the top dead center position on the other side is divided into an acceleration section and a deceleration section, where the stroke length of the mover acceleration section S 1 and the stroke length S of the deceleration section of the mover 2 The sum is a fixed value;

[0040] In the acceleration section, the electromagnetic load is the resistance. By reducing the electromagnetic load of the motor, the acceleration of the mover in this stage is increased, and the acceleration section S is reduced. 1 travel time;

[0041] In the deceleration section, the size of the electromagnetic load is controlled so that the travel S of the mover in this section 2 Complete the action from a certain movement speed to zero in the middle, shorten the deceleration stage time.

[0042...

Embodiment 2

[0129] The purpose of this embodiment is to provide a computing device, including a memory, a processor, and a computer program stored in the memory and operable on the processor. When the processor executes the program, the method in the first embodiment above is realized. step.

Embodiment 3

[0131] The purpose of this embodiment is to provide a computer-readable storage medium.

[0132] A computer-readable storage medium, on which a computer program is stored. When the program is executed by a processor, the steps of the method in the first embodiment above are performed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com