Deformation and displacement measurement method in model test based on image processing

A model test and displacement measurement technology, applied in image data processing, measurement devices, image analysis, etc., can solve the problems of complex methods, complex measurement principles, increased workflow and workload, etc. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

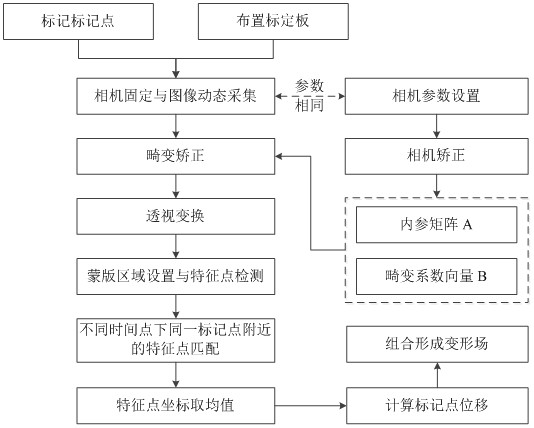

[0071] A method for measuring deformation and displacement in a model test based on image processing, comprising the steps of:

[0072] Step 1. Set the camera parameters for the test process to the camera used in the test, perform camera parameter calibration, and obtain the camera internal parameter matrix , and the distortion coefficient vector of the lens ;

[0073] Step 2: Mark the area of the tested model that needs to measure deformation and displacement in the model test, and set multiple marking points; at the same time, arrange a calibration board in the test scene;

[0074] Step 3, fix the camera and set the camera parameters as calibration parameters, and automatically take pictures of the test process at fixed intervals to collect multiple photos;

[0075] Step 4, through the camera internal reference matrix described in step 1 and the vector of distortion coefficients Carry out distortion correction to the photo described in step 3, obtain the image afte...

Embodiment 2

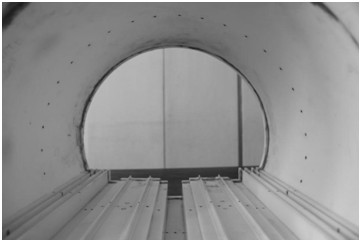

[0120] The present invention provides a method for measuring deformation and displacement in a model test based on image processing. In this embodiment, it is used to measure the full-field deformation of the inner lining of the middle cross-section of a 3D printed tunnel model in a model box during the test. See figure 1 , including the following steps:

[0121] S1: Set the camera parameters of the test process for the Canon 80D camera used in the test, perform camera correction, and obtain the camera internal parameter matrix , and the distortion coefficient vector :

[0122]

[0123]

[0124] S2: Dot marking on the inner side of the lining in the middle cross-section of the 3D printed tunnel model. All marking points are located on the same plane. There are 50 marking points in total. The marking points are . Marking points are marked with an erasable red marker pen for color contrast with the inside of the cream lining and for easy erasing and changes. figure...

Embodiment 3

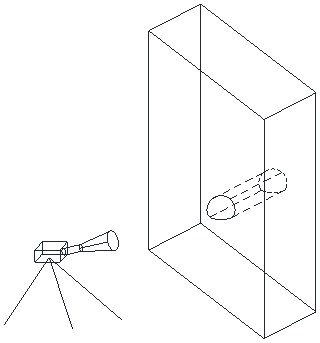

[0147] see figure 1 , the present invention provides a method for measuring deformation and displacement in a model test based on image processing. In this embodiment, it is used to measure the shear displacement of the test block along the bedding in the variable-angle plate shear test. See figure 1 , including the following steps:

[0148] S1: Set the camera parameters of the test process for the Canon 80D camera used in the test, perform camera correction, and obtain the camera internal parameter matrix , and the distortion coefficient vector :

[0149]

[0150]

[0151] S2: Mark a triangular mark point 1 at the two right angles of the variable-angle plate where the variable-angle plate is in contact with the test block. The two mark points 1 are located on the same plane. There are two mark points 1 in total. Mark point 1 as . Marking point 1 is marked with removable red tape for color contrast with the silver-white variable-angle plate shear gauge and for eas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com