Cadmium oxide metallographic specimen and preparation method thereof

A metallographic sample and cadmium oxide technology, which is applied in the field of cadmium oxide metallographic sample and its preparation, can solve the problem that the preparation method has not been reported, achieve clear and complete microstructure, improve work efficiency, and shorten corrosion time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

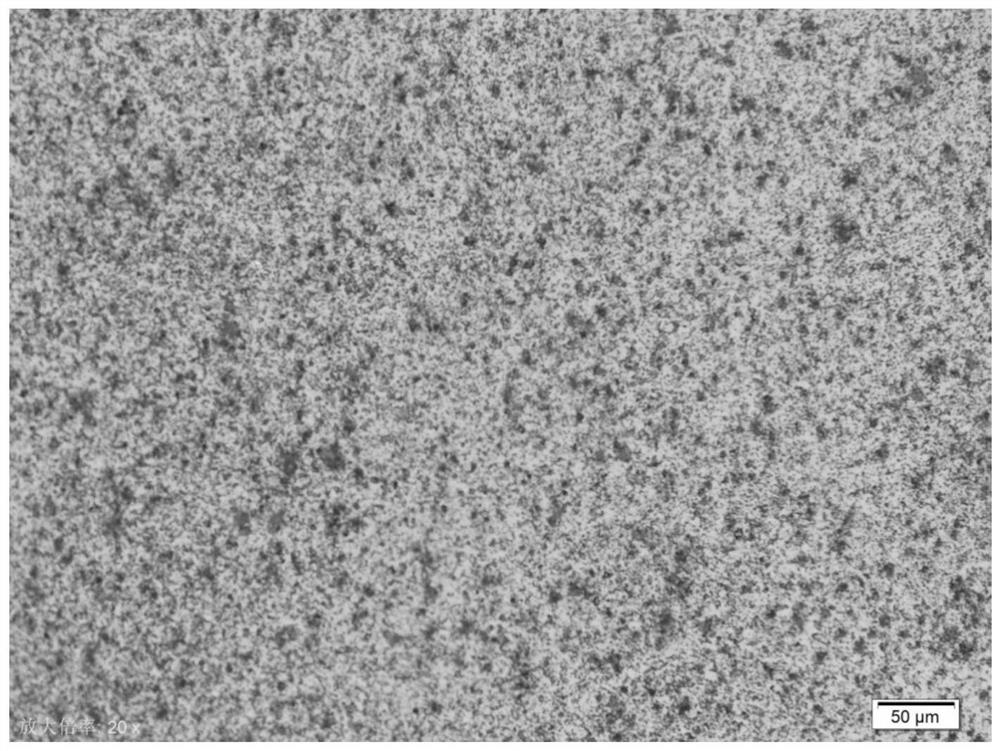

Embodiment 1

[0032] A preparation method for a cadmium oxide metallographic sample, comprising the following steps:

[0033] (1) Cut the cadmium oxide sample on the cadmium oxide target by wire cutting according to the metallographic sample preparation standard;

[0034] (2) Grind the cadmium oxide sample obtained in step (1) with water-based sandpaper of 400, 800, 1500 and 3000 mesh in sequence: when grinding, fix the sandpaper of a predetermined specification on the electric turntable of the polishing machine, and use pure water as the moistening agent. Wet agent, let the turntable rotate clockwise at a speed of 200r / min, then place the cadmium oxide sample in the direction perpendicular to the wire cutting pattern and the tangent of the electric turntable rotation, and apply 20N vertically downward to the metallographic sample After grinding for 2 minutes, rotate the sample 180°, and then polish it with the same method for 2 minutes; then replace the sandpaper, and rotate the sample 90°...

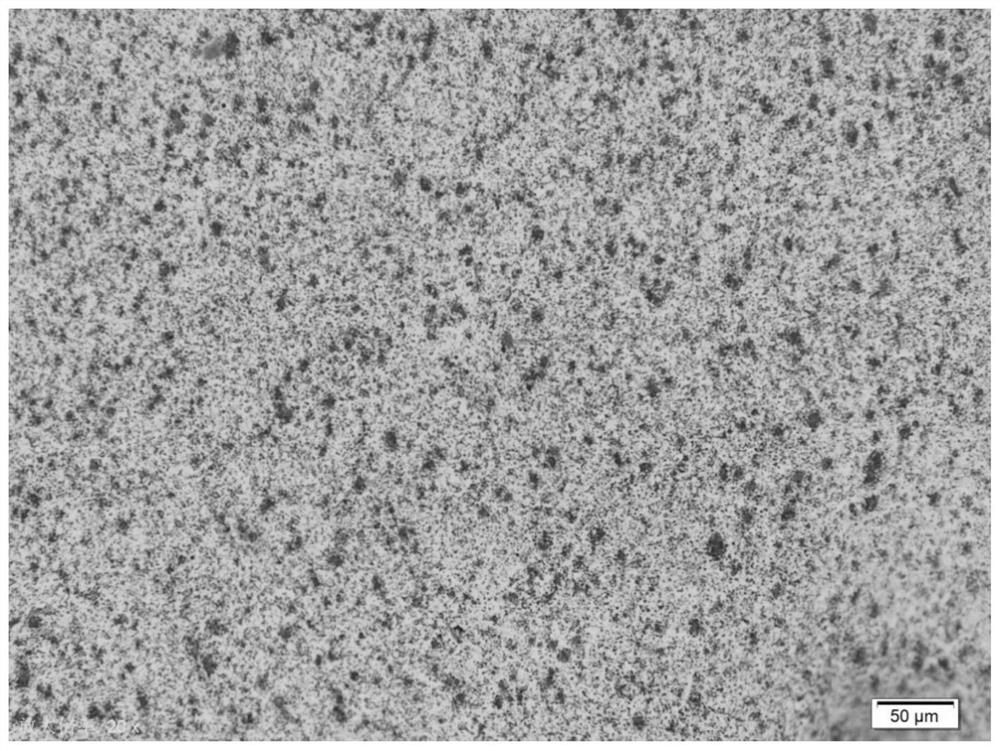

Embodiment 2

[0041] A preparation method for a cadmium oxide metallographic sample, comprising the following steps:

[0042] (1) Cut the cadmium oxide sample on the cadmium oxide target by wire cutting according to the metallographic sample preparation standard;

[0043] (2) Grind the cadmium oxide sample obtained in step (1) with water-based sandpaper of 400, 800, 1500 and 3000 mesh in sequence: when grinding, fix the sandpaper of a predetermined specification on the electric turntable of the polishing machine, and use pure water as the moistening agent. Wet agent, let the turntable rotate clockwise at a speed of 250r / min, then place the cadmium oxide sample in the direction perpendicular to the wire cutting pattern and the tangent of the electric turntable rotation, and apply 20N vertically downward to the metallographic sample After grinding for 3 minutes, rotate the sample 180°, and then polish it in the same way for 3 minutes; then replace the sandpaper, and rotate the sample 90° every ...

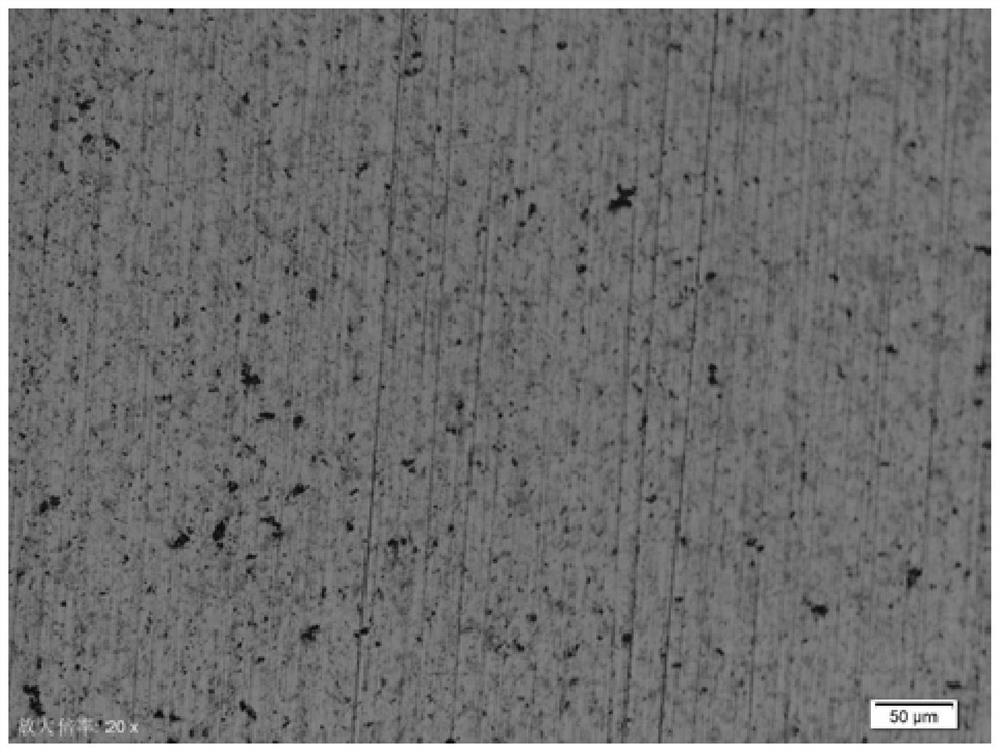

Embodiment 3

[0049] A preparation method for a cadmium oxide metallographic sample, comprising the following steps:

[0050] (1) Cut the cadmium oxide sample on the cadmium oxide target by wire cutting according to the metallographic sample preparation standard;

[0051] (2) Grind the cadmium oxide sample obtained in step (1) with water-based sandpaper of 400, 800, 1500 and 3000 mesh in sequence: when grinding, fix the sandpaper of a predetermined specification on the electric turntable of the polishing machine, and use pure water as the moistening agent. Wet agent, let the turntable rotate clockwise at a speed of 300r / min, then place the cadmium oxide sample in the direction perpendicular to the wire cutting pattern and the tangent of the electric turntable rotation, and apply 20N vertically downward to the metallographic sample After grinding for 5 minutes, rotate the sample 180°, and then polish it in the same way for 5 minutes; then replace the sandpaper, and rotate the sample 90° ever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com