Ocean engineering recycled concrete mix proportion design method based on modified CPM model and corrosion inhibitor protection

A technology of recycled concrete and mix ratio design, which is applied in design optimization/simulation, instrumentation, electrical digital data processing, etc., can solve the problem that marine recycled concrete is difficult to meet the design requirements, etc., to make up for poor physical properties and improve densification. degree, good ecological and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] In this example, recycled coarse aggregate I and recycled fine aggregate I are used to prepare marine recycled concrete. The cementitious material is composed of benchmark cement and slag powder. The mixing water is fresh water. The slump is required to reach 150mm and the strength reaches C40 grade.

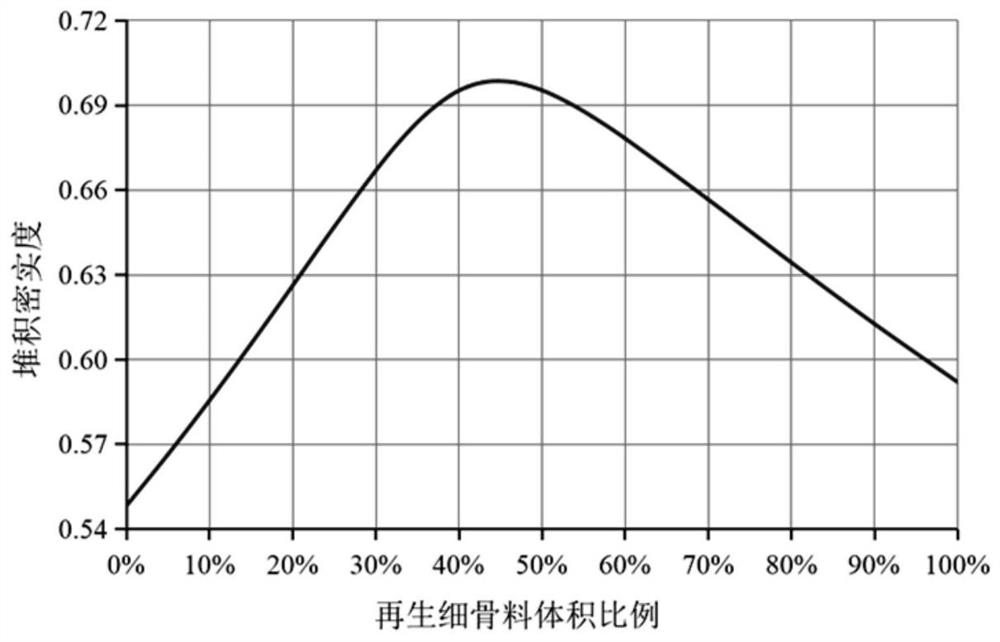

[0063] (1) Use the modified CPM model to calculate the packing density of recycled coarse aggregate and recycled fine aggregate, such as figure 1 As shown, when the volume ratio of recycled fine aggregate is 44.8%, the peak value is 0.698, that is, the concrete volume sand ratio is 44.8%.

[0064] (2) Determine the composition of the cementitious material, the base cement accounts for 80% by volume, and the slag powder accounts for 20%.

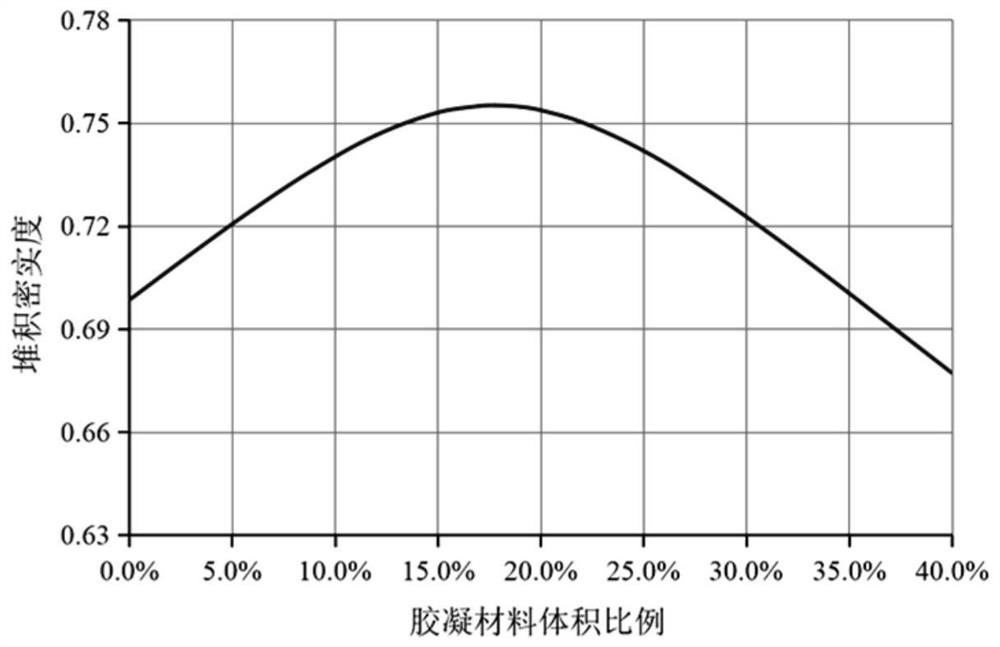

[0065] (3) The volumetric sand ratio remains unchanged at 44.8%. Using the modified CPM model, the packing density of recycled coarse and fine aggregates and cementitious materials is calculated, as shown in figure 2 As shown, when the...

Embodiment 2

[0075] On the basis of Example 1, the mixing water was changed from fresh water to sea water, correspondingly the dosage of sodium metasilicate pentahydrate was increased from 2.0% to 3.0%, and other parameters remained unchanged. At this time, the concrete slump reaches 160mm, the compressive strength at 3d, 7d, and 28d reaches 25.4MPa, 34.7MPa, and 45.1MPa respectively, and the splitting tensile strength at 28d reaches 3.24MPa.

Embodiment 3

[0077] In this example, recycled coarse aggregate II and recycled fine aggregate II are used to prepare marine recycled concrete. The cementitious material is composed of benchmark cement and slag powder. The mixing water is fresh water. The slump is required to reach 150mm and the strength reaches C30 grade.

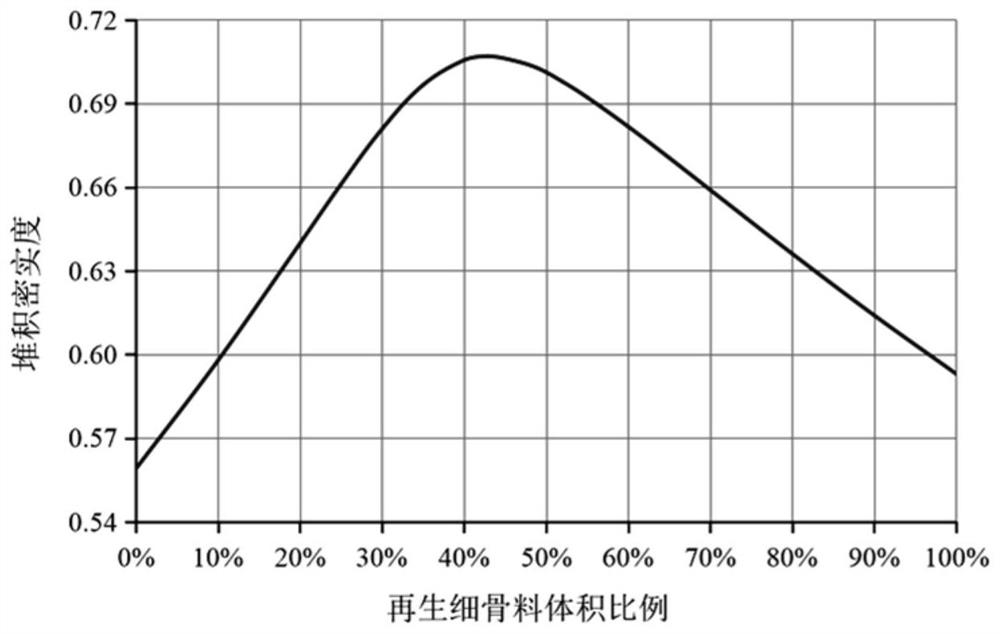

[0078] (1) Use the modified CPM model to calculate the packing density of recycled coarse aggregate and recycled fine aggregate, such as image 3 As shown, when the volume ratio of recycled fine aggregate is 42.9%, the peak value is 0.707, that is, the concrete volume sand ratio is 42.9%.

[0079] (2) Determine the composition of the cementitious material, the base cement accounts for 80% by volume, and the slag powder accounts for 20%.

[0080] (3) The volumetric sand ratio remains unchanged at 42.9%. Using the modified CPM model, calculate the packing density of recycled coarse and fine aggregates and cementitious materials, as shown in Figure 4 As shown, when the v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Splitting tensile strength | aaaaa | aaaaa |

| Slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com