Iron-nitrogen doped core-shell carbon sphere material and preparation method thereof

An iron-doped, core-shell technology, applied in nanotechnology for materials and surface science, electrical components, battery electrodes, etc., can solve problems such as porous structure collapse, limit material transport, reduce surface area, etc., to promote graphitization degree, high ORR activity, enhanced conductivity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

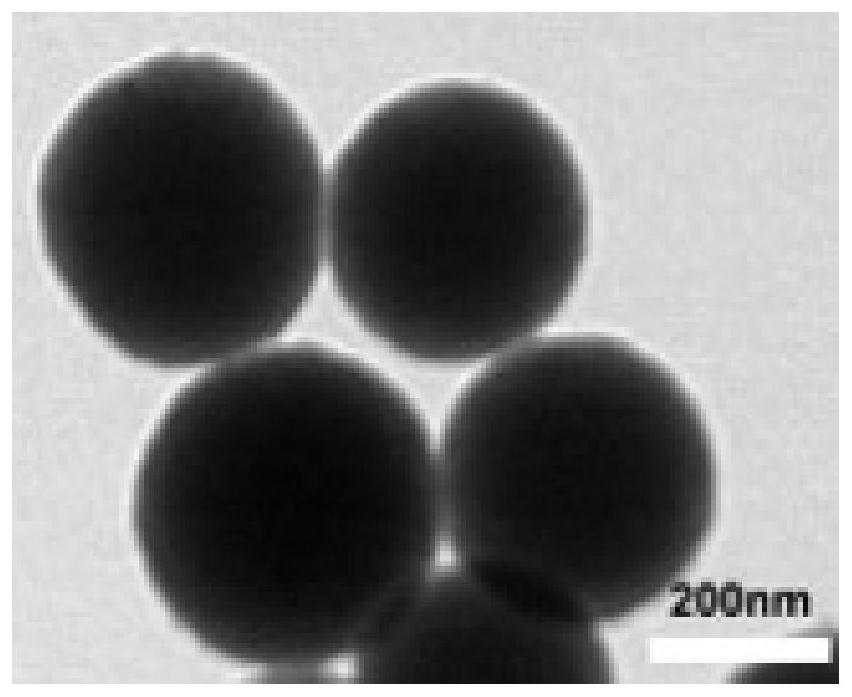

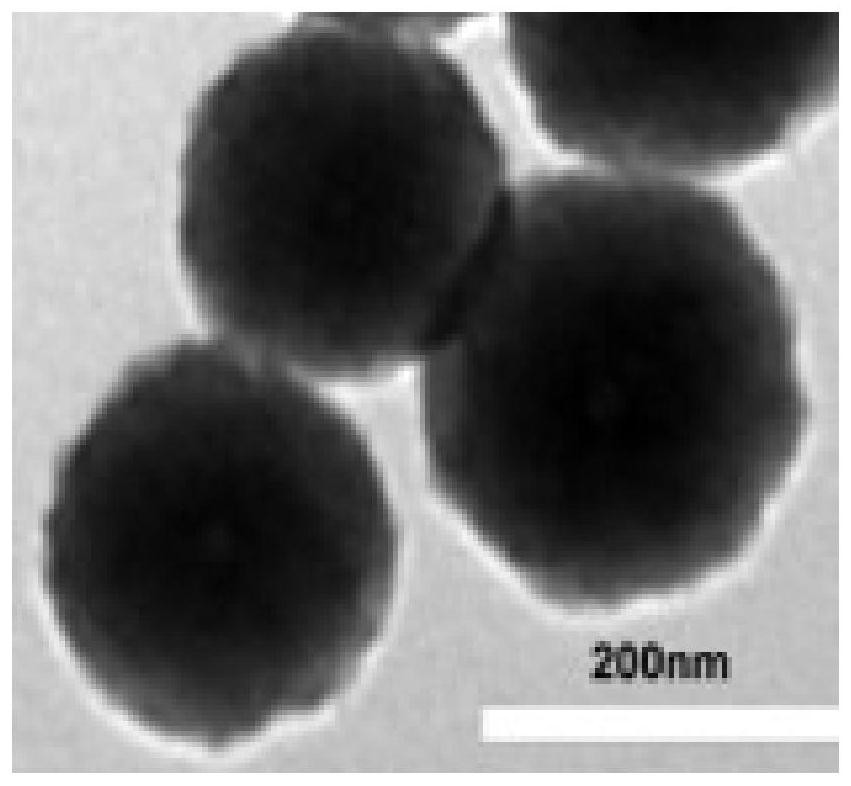

[0026] An embodiment of the preparation method of the iron-nitrogen-doped core-shell carbon sphere material of the present invention, the preparation method described in this embodiment includes the following steps:

[0027] (1) Synthesis of PDA balls: Mix 112mL deionized water and 28mL methanol, then drop 1.5mL ammonia water into the mixture to obtain solution A; add 0.5g dopamine hydrochloride to solution A, stir for 30h, and centrifuged at 8500rpm for 3min, washed 3 times with methanol and ethanol, and dried in a vacuum oven for 12h to obtain the PDA spheres;

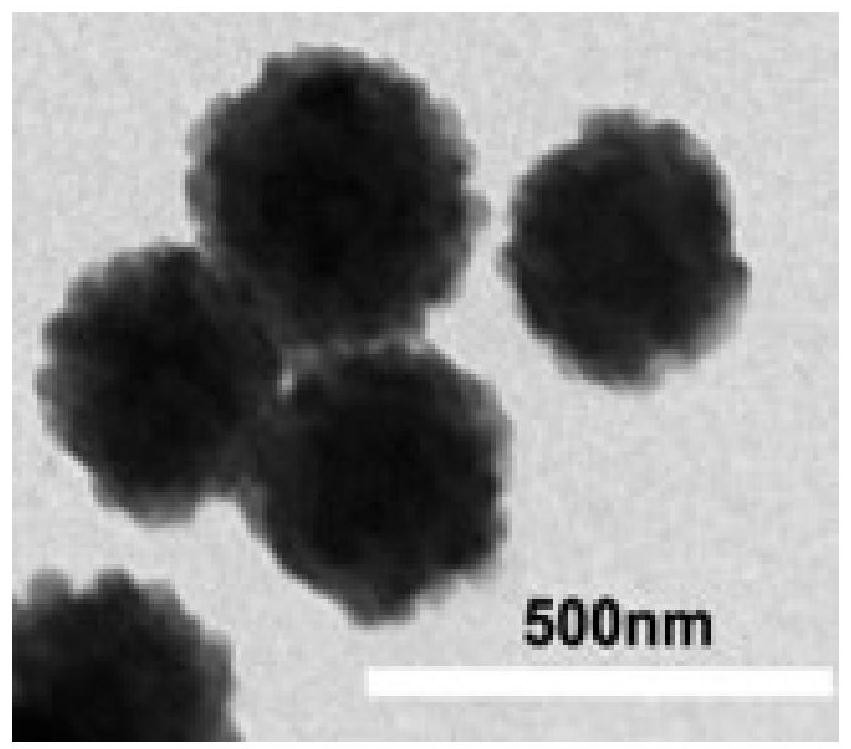

[0028] (2) Preparation of PDA@ZIF-8-Fe: Add 0.1g of PDA balls into 30mL of methanol, ultrasonically disperse for 10min to obtain a dispersion; then add 0.22g of zinc nitrate hexahydrate, 0.49g of 2-methyl imidazole and 0.02g ferric nitrate nonahydrate, stirred for 15h, centrifuged, washed with methanol three times, and then dried in a vacuum oven at 60°C for 12h to obtain the PDA@ZIF-8-Fe;

[0029] (3) Preparation o...

Embodiment 2

[0031] An embodiment of the preparation method of the iron-nitrogen-doped core-shell carbon sphere material of the present invention, the difference between this embodiment and the embodiment 1 is that the addition amount of iron nitrate nonahydrate is 0.01 g.

Embodiment 3

[0033] An embodiment of the preparation method of the iron-nitrogen-doped core-shell carbon sphere material of the present invention, the difference between this embodiment and the embodiment 1 is that the addition amount of iron nitrate nonahydrate is 0.04 g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com