Full-automatic intelligent rubber tapping robot

A fully automatic and robotic technology, applied in agriculture, forestry, applications, etc., can solve the problem of high labor cost, achieve the effect of large working area, good promotion and use value, and reduce input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Firstly, the present invention will be further described with reference to the drawings and embodiments.

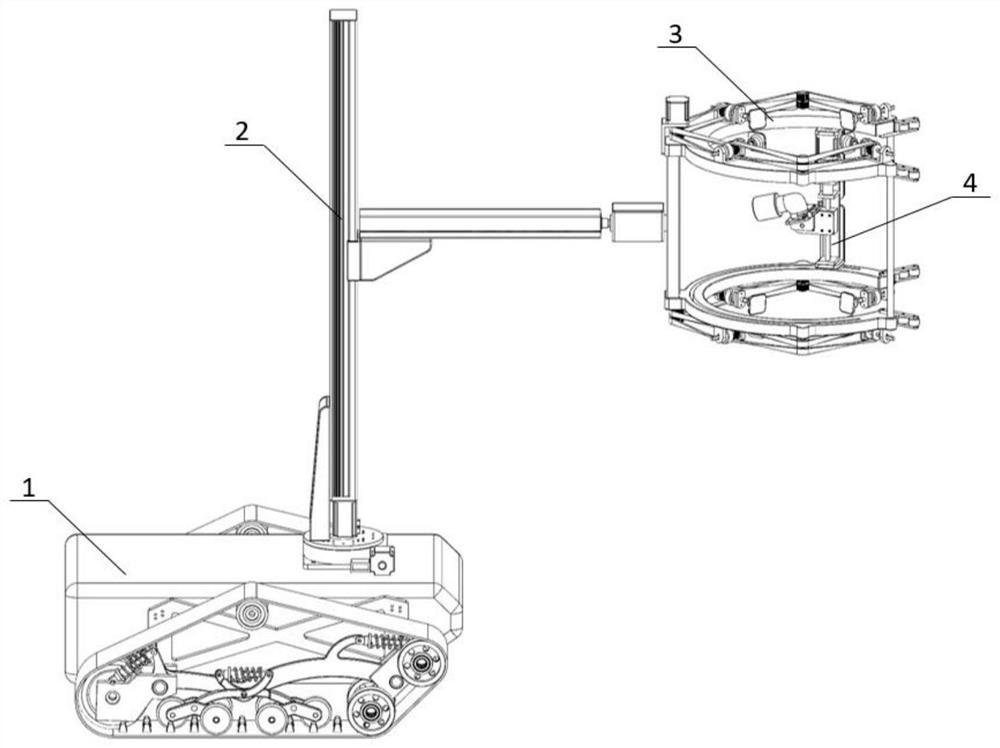

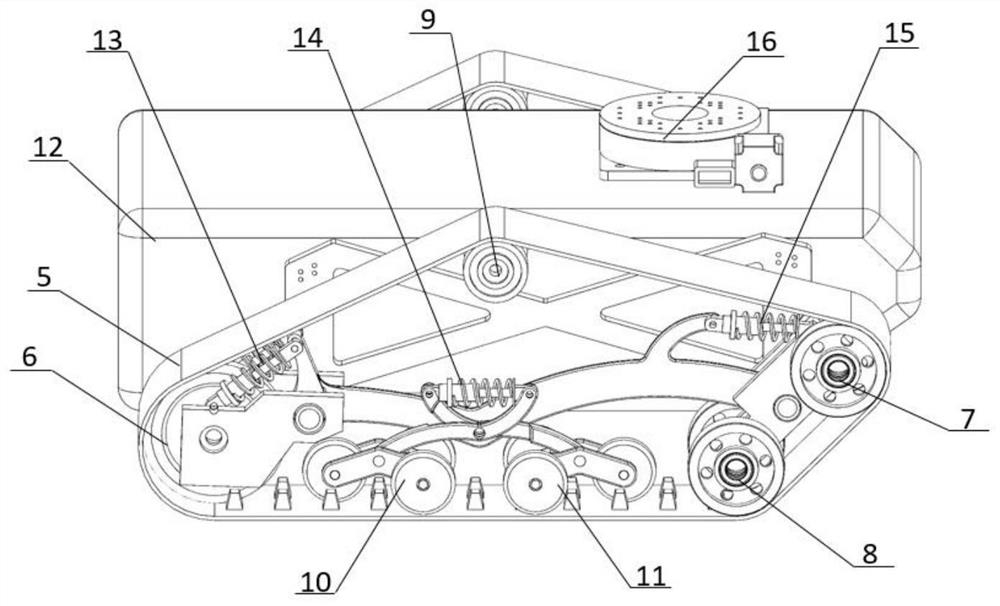

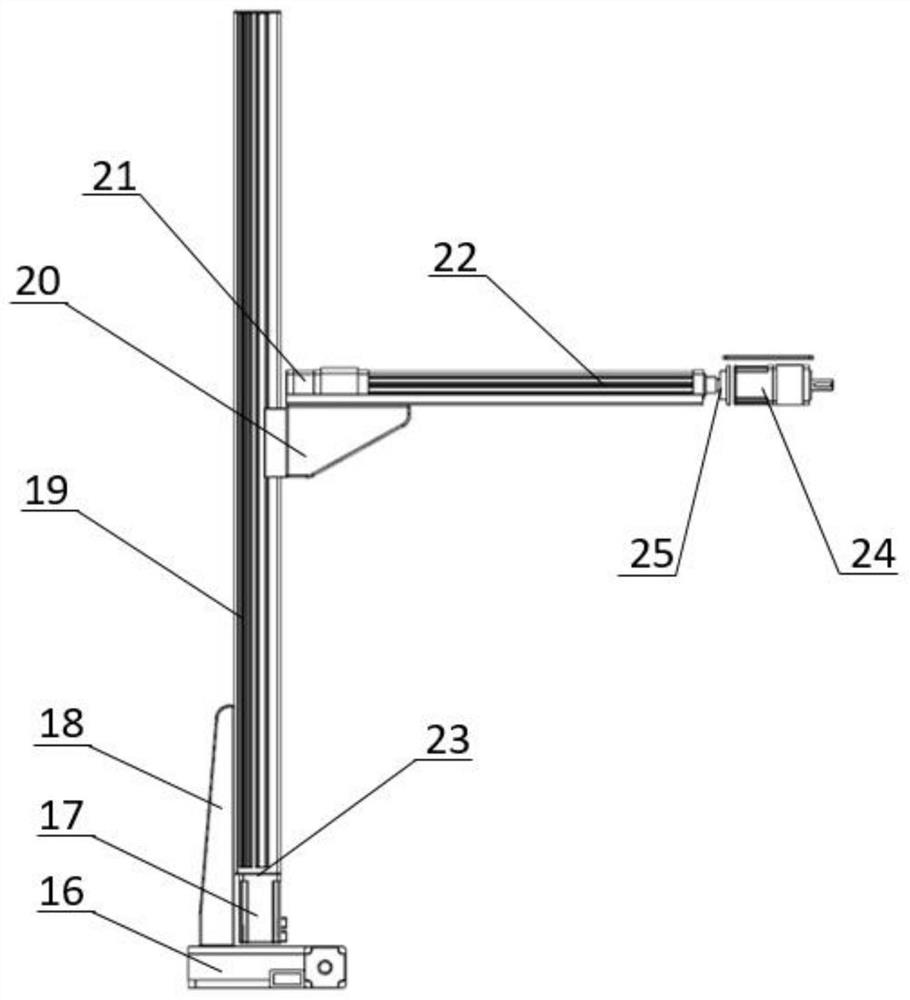

[0037] Device embodiment: refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5. First introduce the collation structure. The present invention is a fully automatic rubber tapping robot system, which mainly includes: a crawler-type mobile platform 1, which is a movable platform with a crawler structure and has a certain shock-absorbing ability, and is mainly responsible for carrying related equipment and moving between rubber forests. The rubber tapping work provides a stable platform, etc.; the rubber tapping mechanical arm 2 is connected with the electric rotary table 16 located on the crawler mobile platform 1 through the connecting plate 18, and its structure is a four-degree-of-freedom mechanical arm with vertical rotation and expansion and horizontal rotation. With four degrees of freedom of expansion and contraction, it can meet the working ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com