Degradable and high-toughness composite material and preparation method thereof

A composite material, strong and tough technology, applied in medical science, surgery, etc., can solve the problems of fast degradation rate, insufficient mechanical properties of composite materials, poor connection performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

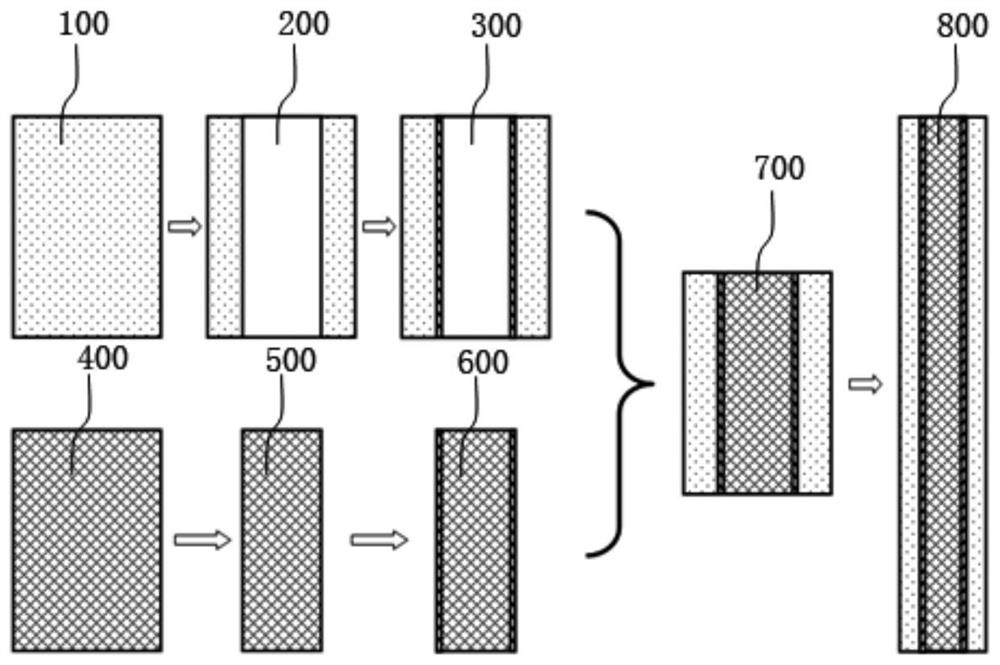

[0116] Embodiment 1: the preparation of composite material

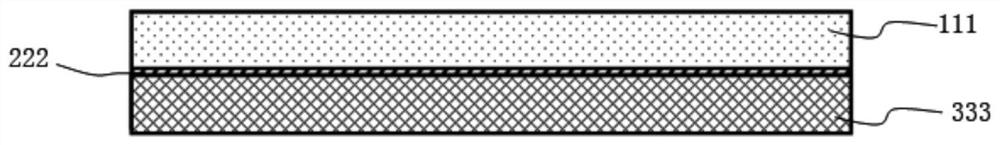

[0117] A flat plate-shaped degradable, strong and tough composite material, by volume percentage, including 39% of the zinc alloy layer, 1% of the intermediate alloy layer and 60% of the magnesium alloy layer; the intermediate alloy layer is composed of magnesium-zinc alloy powder; the zinc alloy layer The layer does not contain Mg; the magnesium alloy layer does not contain Zn.

[0118] The zinc alloy layer is composed of zinc alloy, and zinc alloy, by mass percentage, includes the following components:

[0119] Y 3.5%

[0120] Nd 3.0%;

[0121] The magnesium alloy layer is made of magnesium alloy, and the magnesium alloy, by mass percentage, includes the following components:

[0122] Y 3.5%

[0123] Nd 3.0%;

[0124] The preparation method of above-mentioned zinc alloy comprises the following steps:

[0125] (1) Weigh Y, Nd, Zn (residue) according to the proportion, then vacuum smelting, the temperature of v...

Embodiment 2

[0140] Embodiment 2: the preparation of composite material

[0141] A flat plate-shaped degradable, strong and tough composite material, by volume percentage, including 29% of the zinc alloy layer, 2% of the intermediate alloy layer and 69% of the magnesium alloy layer; the intermediate alloy layer is composed of magnesium-zinc alloy powder; the zinc alloy layer The layer does not contain Mg; the magnesium alloy layer does not contain Zn.

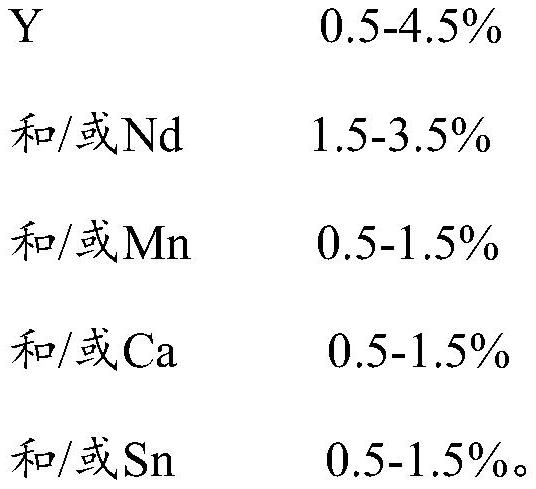

[0142] The zinc alloy layer is composed of zinc alloy, and zinc alloy, by mass percentage, includes the following components:

[0143]

[0144]

[0145] The magnesium alloy layer is made of magnesium alloy, and the magnesium alloy, by mass percentage, includes the following components:

[0146]

[0147] The preparation method of above-mentioned zinc alloy comprises the following steps:

[0148] (1) Weigh Y, Nd, Mn, Ca, Sn, Zn (remainder) according to the proportion, and then vacuum smelt. The temperature of vacuum smelting is 680...

Embodiment 3

[0162] Embodiment 3: the preparation of composite material

[0163] A kind of degradable, strong and tough composite material in the shape of a round bar. According to the volume percentage, from the outside to the inside, there are 39% of the zinc alloy layer, 1% of the intermediate alloy layer and 60% of the magnesium alloy layer; the intermediate alloy layer is composed of magnesium Composed of zinc alloy powder; the zinc alloy layer does not contain Mg; the magnesium alloy layer does not contain Zn.

[0164] The zinc alloy layer is composed of zinc alloy, and zinc alloy, by mass percentage, includes the following components:

[0165] Y 3.0%

[0166] Nd 2.5%

[0167] Mn 1.0%;

[0168] The magnesium alloy layer is made of magnesium alloy, and the magnesium alloy, by mass percentage, includes the following components:

[0169] Y 3.0%

[0170] Nd 2.5%

[0171] Mn 1.0%;

[0172] The preparation method of zinc alloy, magnesium alloy and magnesium-zinc alloy powder is the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com